Device for attaching terminating tape to battery through winding

A technology of battery roll and adhesive paper, which is applied in secondary battery manufacturing, transportation and packaging, and final product manufacturing, etc. It can solve the problems that the end glue head is easy to turn up or down, affecting the glue application, etc., so as to avoid upturning , the effect of reducing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

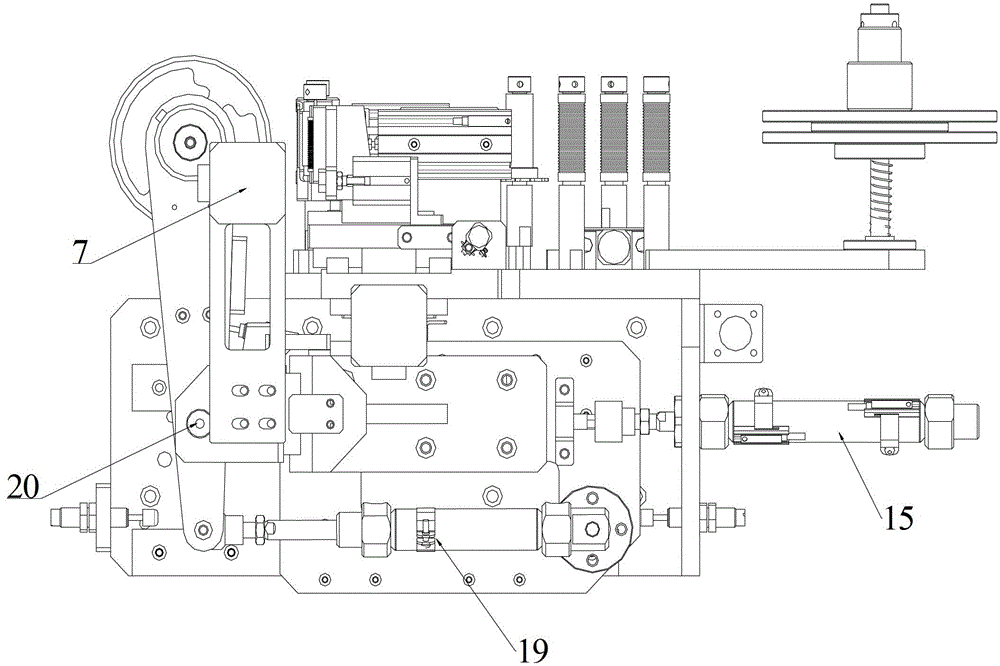

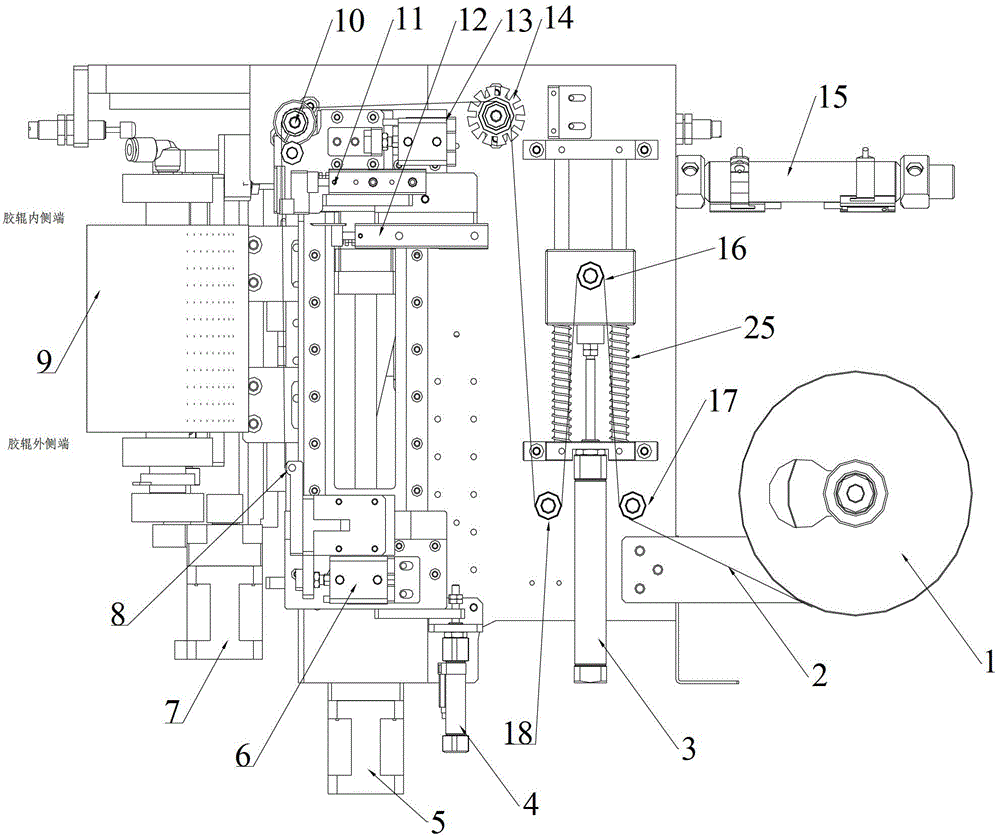

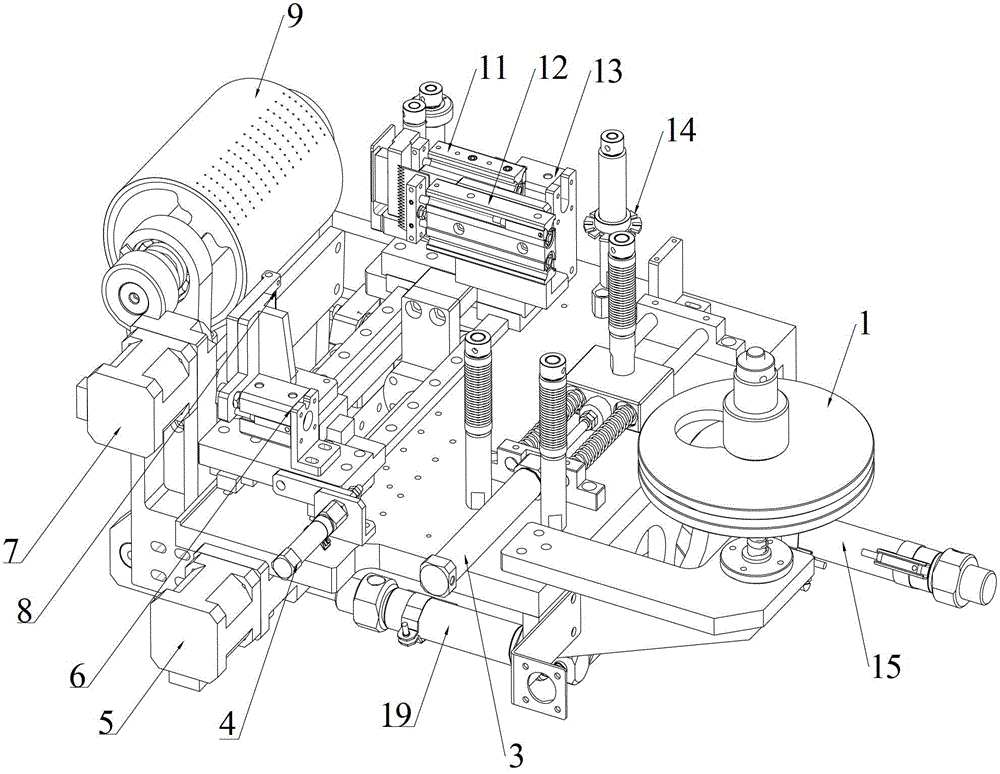

[0037] In this example, the device for wrapping and pasting the termination glue on the battery, such as Figure 1-4 As shown, it includes a gluing roller 9, a gluing assembly, a gluing paper drive assembly 5 that transports the gluing assembly from one end of the gluing roller to the other end, and a gluing head that presses the terminated glue on the gluing roller 9 8. The glue pulling assembly includes a fixing plate 23 and a pressure paper cylinder pressure head 22 for pressing the terminated glue on the fixing plate. The pressure paper cylinder pressure head 22 has a toothed pressing portion. In this example, it also includes a cutting knife 24 and a tape cutting cylinder 12 for driving the cutting knife, and a tape moving cylinder 13 . The cutter 24 and the glued paper cutting cylinder 12 are arranged on the inner side of the glue pulling assembly. The adhesive paper moving cylinder 13 is driven and connected with the rubber pulling assembly, and the pressure head 22 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com