Liquid activated zinc manganese paper battery and preparation method thereof

A liquid activation, zinc-manganese paper technology, applied in the electrodes of primary batteries, dry batteries, etc., can solve the problems of capacity reduction and performance degradation, and achieve the effects of excellent performance, wide application and excellent storage performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

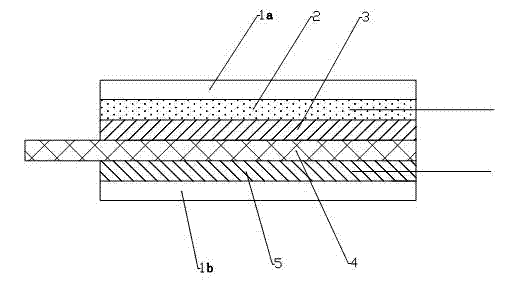

Image

Examples

Embodiment 1

[0028] Example 1. Fabrication of liquid-activated zinc-manganese paper monolithic paper batteries.

[0029] (1) Preparation of electrolyte, according to ZnCl 2 : NH 4 Cl: CaCl 2 =10:25:3 mass ratio preparation.

[0030] (2) Handling of fiber paper. Soak the filter paper in the above electrolyte solution for 2-3 minutes, drain the excess dripping liquid, and dry it at 40-50°C for later use.

[0031] (3) MnO 2 Preparation of mixed powder materials, according to electrolytic MnO 2 : carbon black: ZnO=9:1:0.1 mass ratio mixed, and ball milled into MnO 2 Mix the powder.

[0032] (4) MnO 2 The preparation of the slurry and its coating, the MnO 2 Mixed powder and deionized water to prepare MnO 2 active slurry, then the MnO 2 The active slurry is scraped and coated on the surface of the pulp layer paper, and dried at 40-50 degrees Celsius for later use.

[0033] (5) For the production of liquid-activated zinc-manganese paper batteries, first cut the filter paper adsorbed ...

Embodiment 2

[0035] Example 2. Fabrication of liquid-activated zinc-manganese monolithic paper batteries.

[0036] (1) Preparation of electrolyte, according to ZnCl 2 : NH 4 Cl: CaCl 2 =20:10:5 mass ratio preparation.

[0037] (2) Handling of fiber paper. Soak the quick-absorbing paper in the above electrolyte for 2-3 minutes, drain the excess dripping liquid, and dry it at 40-50°C for later use.

[0038] (3) MnO 2 Preparation of mixed powder materials, according to active MnO 2 : Carbon nanotubes: V 2 o 5 =9:1:0.1 mass ratio mixed and ball milled into MnO 2 Mix the powder.

[0039] (4) MnO 2 Preparation of active slurry and its coating, the MnO 2 The mixed powder is mixed with deionized water to prepare MnO 2 active slurry, then the MnO 2 The active slurry is scraped on the surface of the pulp layer paper and dried at 40-50 degrees Celsius for later use.

[0040] (5) For the production of liquid-activated zinc-manganese paper batteries, first cut the fast-absorbing paper a...

Embodiment 3

[0042] Example 3. Fabrication of liquid-activated zinc-manganese monolithic paper batteries.

[0043] (1) Preparation of electrolyte, according to ZnCl 2 : NH 4 Cl: CaCl 2 =20:20:5 mass ratio preparation.

[0044] (2) Handling of fiber paper. Soak the filter paper in the above electrolyte solution for 2-3 minutes, drain the excess dripping liquid, and dry it at 40-50°C for later use.

[0045] (3) MnO 2 Preparation of mixed powder materials, according to fiber MnO 2 : carbon nanotubes: zeolite = 9:0.5:0.1 mass ratio mixed and ball milled into MnO 2 Mix the powder.

[0046] (4) MnO 2 Preparation of active slurry and its coating, the MnO 2 The mixed powder is mixed with deionized water to prepare MnO 2 active slurry, then the MnO 2 The active slurry is scraped on the surface of the pulp layer paper and dried at 40-50 degrees Celsius for later use.

[0047] (5) For the production of liquid-activated zinc-manganese paper batteries, first cut the dry filter paper adsor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com