Automatic temperature control method and device for optical fiber coating

An optical fiber and coating technology, applied in the field of optical fiber processing, can solve the problems such as difficulty in meeting the requirements of high-speed wire drawing coating, difficulty in ensuring optical fiber coating quality, coating defects, etc., and achieves easy implementation and promotion, simple structure, and reduced The effect of paint spillage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

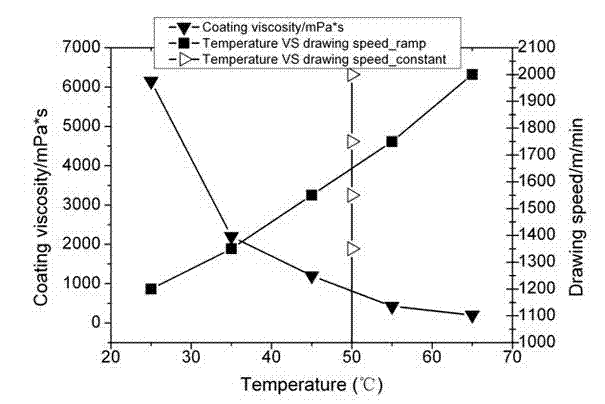

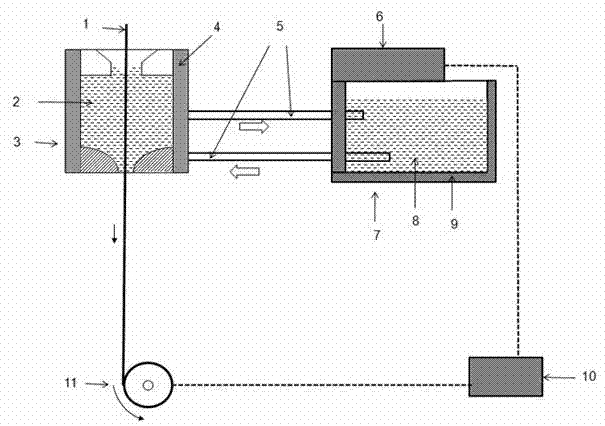

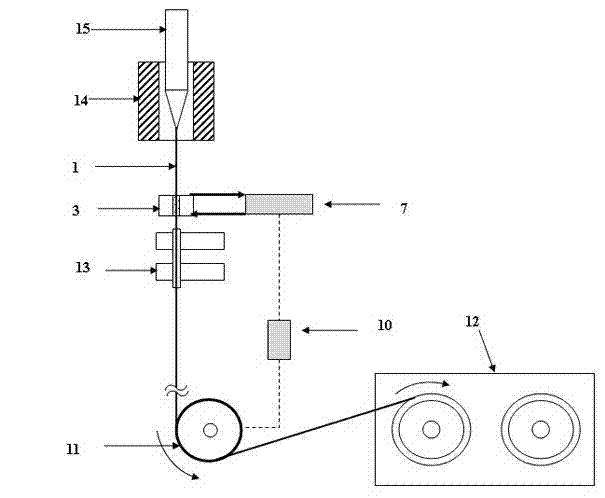

[0021] like figure 2 As shown, the drawing process of the optical fiber includes: the glass preform 15 is heated and softened in the drawing furnace 14 to form the optical fiber 1, and the optical fiber enters the optical fiber coater 3 after cooling and forming, and the optical fiber coater is conducted by the circulation heater 7 through the circulation pipe with liquid heat conduction. The medium is used for circulating heating and temperature control. The temperature sensing signal of the circulating heater is associated with the speed sensing signal of the traction wheel 11 through the PLC unit 10. The temperature control process of the circulating heater directly affects the quality of the optical fiber coating layer. After the coating is coated on the surface of the optical fiber, it enters the curing device 13 to cure the coating. After the opt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com