Device and method for measuring rotational speed of engine based on differential pressure signals of exhaust back pressure

A technology of engine speed and difference signal, applied in the direction of using fluid devices, etc., can solve the problems of affecting the whole vehicle line and increasing the cost, and achieve the effect of simple structure, easy installation and debugging, and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, patent of the present invention is described further.

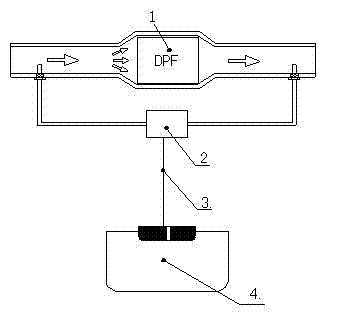

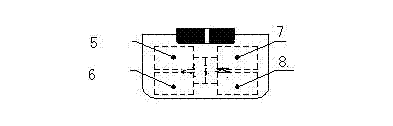

[0016] Such as figure 1 and figure 2 As shown, the device for measuring the engine speed based on the exhaust back pressure differential signal of the present invention includes: a DPF particle trap 1; an exhaust back pressure differential sensor 2; a signal transmission cable 3; a controller 4; The differential sensor is installed at the front and rear ends of the particle trap, and the exhaust back pressure differential sensor is connected to the controller through a signal transmission cable; the controller is equipped with a signal conditioning unit 5, a signal processing unit 6, and a signal analysis unit 7 connected in sequence and communication unit 8. In the specific implementation, the signal conditioning unit can use the bandpass filter composed of the AD810 chip. The signal processing unit is to collect the conditioning signal and perform Fourier tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com