Broadwise elastic fabric and purpose thereof

A technology of elastic fabric and weft direction, which is applied in the field of textiles and can solve the problems of thick fabrics and narrow application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

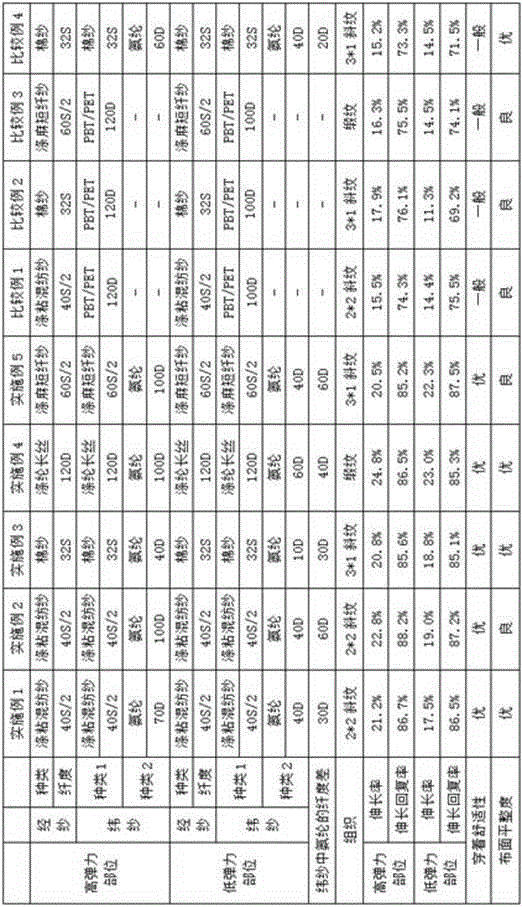

Examples

Embodiment 1

[0022] The warp yarn uses 40S / 2 polyester viscose blended yarn, the weft yarn 1 is the core-spun yarn of 40S / 2 polyester viscose blended yarn and 40D spandex, the weft yarn 2 is the core-spun yarn of 40S / 2 polyester viscose blended yarn and 70D spandex, and the warp yarn The tension on the upper machine is 3.0 centinewtons / dtex, the speed of the loom is 800 rpm, the warp and weft density is 116*69 threads / inch, and the gray fabric (62% polyester, 34% viscose, Spandex 4%).

[0023] Then through the following processing, gray fabric preparation → desizing and refining 95°C → relaxation 120°C * 30min → intermediate setting 195°C * 40m / min → dyeing (disperse dye 128°C, reactive dye 60°C) → finishing and setting 190°C * 40m / min min → weft elastic fabric.

[0024] The obtained weft elastic fabric has a length of 30cm at the warp-up high elastic part and a length of 100cm at the low elastic part; according to the JIS L 1096:2010B standard, the weft elastic elongation of the low elas...

Embodiment 2

[0026] The warp yarn uses 40S / 2 polyester viscose blended yarn, the weft yarn 1 is the core-spun yarn of 40S / 2 polyester viscose blended yarn and 40D spandex, the weft yarn 2 is the core-spun yarn of 40S / 2 polyester viscose blended yarn and 100D spandex, and the warp yarn The tension on the upper machine is 3.0 centinewtons / dtex, the speed of the loom is 800 rpm, the warp and weft density is 116*70 threads / inch, and the gray fabric (polyester 62%, viscose 33%, Spandex 5%).

[0027] Then through the following processing, gray fabric preparation → desizing and refining 95°C → relaxation 120°C * 30min → intermediate setting 195°C * 40m / min → dyeing (disperse dye 128°C, reactive dye 60°C) → finishing and setting 190°C * 40m / min min → weft elastic fabric.

[0028] The obtained weft elastic fabric has a length of 30cm at the warp-up high elastic part and a length of 100cm at the low elastic part; according to the JIS L 1096:2010B standard, the weft elastic elongation of the low ela...

Embodiment 3

[0030] The warp yarn is 32S cotton yarn, the weft yarn 1 is the core-spun yarn of 32S cotton yarn and 10D spandex, and the weft yarn 2 is the core-spun yarn of 32S cotton yarn and 40D spandex. The density design is 110*70 threads / inch, and the gray fabric (94% cotton, 6% spandex) is made by adopting striped dobby 3*1 twill weave.

[0031] Then through the following processing, gray fabric preparation → desizing and scouring 95 ° C → relaxation 120 ° C * 30 min → intermediate setting 195 ° C * 40m / min → dyeing (reactive dye 60 ° C) → finishing and setting 190 ° C * 40 m / min → weft elasticity fabric.

[0032] Gained weft elastic fabric has a length of 20cm at the warp-up high elastic part and a length of 60cm at the low elastic part; according to the JIS L 1096:2010B standard, the weft elastic elongation of the low elastic part is 18.8%, and the weft elongation recovery rate is 85.1%; The weft elastic elongation of the high elastic part is 20.8%, and the weft elongation recover...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com