Process for producing high magnetic ferroferric oxide by galvanized pickle liquor

A technology of galvanizing pickling waste liquid and ferroferric oxide, which is applied in the direction of iron oxide/iron hydroxide, oxides of ferrous iron, chemical instruments and methods, etc., can solve the problem of low-grade iron compounds, complicated process flow, Difficult to popularize and apply, etc., to achieve the effect of high added value, wide source of raw materials, and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

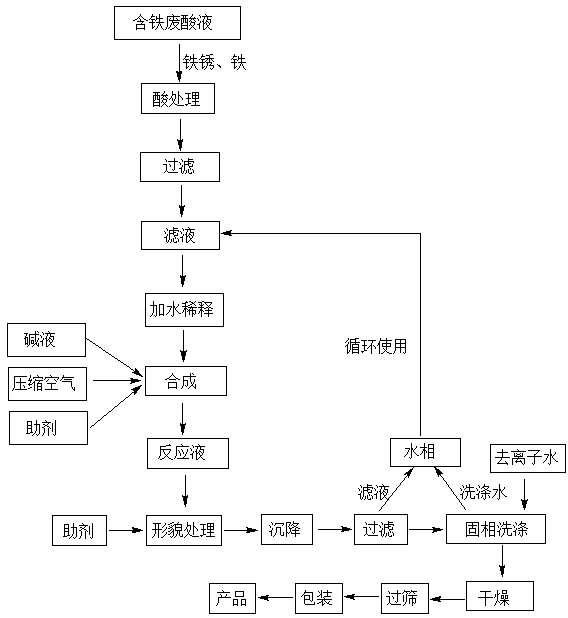

Method used

Image

Examples

Embodiment 1

[0049] Rust and iron were added to the iron-containing waste acid solution of a galvanizing plant to consume the free acid in the solution, and then filtered through a 800-mesh filter cloth. Transfer 240 ml of filtered filtrate to a reaction kettle, and add 160 ml of water to the reaction kettle for dilution. Turn on the heating device for heating, and turn on the stirring for slow stirring. When the heating temperature reaches 50°C, the stirring rate is controlled at 300r / min, and 3 mol L -1 200 ml of sodium hydroxide solution, the pH of the control solution is 6.0. Add polydimethyldipropylene ammonium chloride (0.5g) and 3-chloro-2-hydroxypropyltrimethylammonium chloride chitosan (0.5g) in turn to the reaction kettle. Air is introduced, and the air flow rate is controlled at 0.5 m 3 / h. When detecting Fe in the system 3+ with Fe 2+ When the molar ratio is 1.8, the aeration is stopped.

[0050] Add 20 ml 3 mol·L -1 Sodium hydroxide solution, control the pH of the solu...

Embodiment 2

[0054] Rust and iron were added to the iron-containing waste acid solution of a galvanizing plant to consume the free acid in the solution, and then filtered through a 800-mesh filter cloth. 480 ml of the treated filtrate was transferred to the reactor, and 320 ml of water was added to the reactor for dilution. Turn on the heating device for heating, and turn on the stirring for slow stirring. When the heating temperature reached 70°C, the stirring rate was controlled at 200r / min, and 3 mol L -1 205 ml of sodium hydroxide solution, the pH of the control solution is 6.5. 2-Hydroxypropyltrimethylammonium chloride chitosan (1.2 g) was added to the kettle. Air is introduced, and the air flow rate is controlled at 0.8 m 3 / h. When detecting Fe in the system 3+ with Fe 2+ When the molar ratio is 2.2, the aeration is stopped.

[0055] Add 20 ml 3 mol·L -1 sodium hydroxide solution, control the pH of the solution to 10.5, then add N, N , - Sodium dipalmitoyl ethylenediamine d...

Embodiment 3

[0059] Rust and iron were added to the iron-containing waste acid solution of a galvanizing plant to consume the free acid in the solution, and then filtered through a 800-mesh filter cloth. Transfer 240 ml of filtered filtrate to a reaction kettle, and add 160 ml of water to the reaction kettle for dilution. Turn on the heating device for heating, and turn on the stirring for slow stirring. When the heating temperature reached 85 °C, the stirring rate was controlled at 100 r / min, and 3 mol L -1 200 ml of sodium hydroxide solution, the pH of the control solution is 6.0. Add polydimethyldipropenyl ammonium chloride (0.7g) and iodide N-trimethylammonium chloride chitosan (0.8g) in turn to the reaction kettle. Air is introduced, and the air flow rate is controlled at 1.0 m 3 / h. When detecting Fe in the system 3+ with Fe 2+ When the molar ratio is 2.1, the aeration is stopped.

[0060] Add 20 ml 3 mol·L -1 sodium hydroxide solution, control the pH of the solution to 10, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com