A method for manufacturing a composite sound-absorbing diamond saw blade matrix

A technology of diamond saw blade and manufacturing method, which is applied in the direction of cutting tool manufacturing, manufacturing tools, metal sawing equipment, etc. of sawing machine devices, and can solve the constraints on the process quality, processing efficiency and processing cost of composite sound-absorbing diamond saw blade base products, sawing The flatness of the blade substrate and the stress difference increase the difficulty of leveling, and the single saw blade substrate has many procedures, so as to achieve the effects of shortening the processing cycle, reducing the cost of raw materials, and shortening the process cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

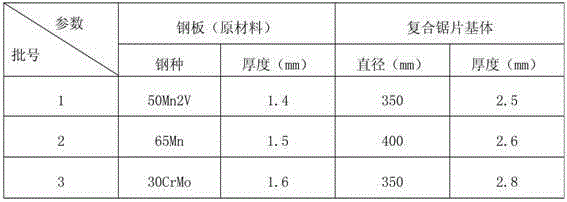

[0030] The present invention manufactures the manufacture method of composite sound-absorbing diamond saw blade matrix as follows:

[0031] 1) Equipped with a single saw blade base

[0032] Using the cold-rolled saw blade base steel plate as raw material, the single saw blade base is obtained after the overall punching and removal of burrs;

[0033] 2) Combination seam welding

[0034] Take two single saw blade substrates, clamp a layer of damping material between the two single saw blade substrates, and then perform seam welding on the combined saw blade substrate along the circumferential direction. After the seam welding is completed, a composite sound-absorbing diamond Saw blade base blank;

[0035] 3) Quenching and tempering

[0036] Quenching and tempering the composite sound-absorbing diamond saw blade base blank;

[0037] 4) Finishing

[0038] After quenching and tempering, the base blank of the compound noise-absorbing diamond saw blade is finished, including fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com