Jet flow rotor gyroscope based on expansion-shrinkage pipe micropump

A jet rotor and shrink tube technology, applied in the field of inertial measurement, can solve the problems of temperature rise, affecting the detection accuracy of jet rotor gyroscope, and the vibration cavity cannot complete alternate air injection and suction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

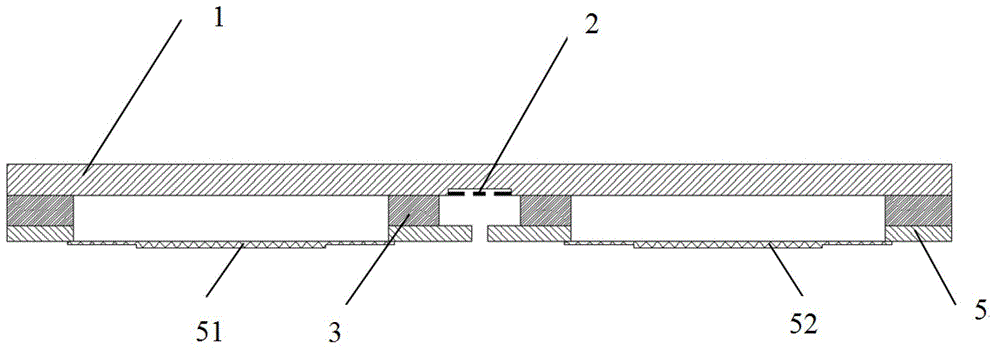

[0019] refer to Figure 1-6 , a jet rotor gyroscope based on an expanding-shrinking tube micropump, refer to Figure 1-5 , including an upper sealing layer 1, a thermistor layer 2, a cavity layer 3 and a lower sealing layer 5 in turn; the cavity layer 3 has a through cylindrical cavity, and vibrations are evenly distributed in the outer circumferential direction of the cylindrical cavity Cavity I31 and vibration cavity II32; both vibration cavity I31 and vibration cavity II32 do not penetrate the cavity layer 3, and the parts that do not penetrate form corresponding vibrating films respectively; each vibrating film is connected with a piezoelectric film I51 and a piezoelectric film II52; the cylindrical cavity communicates with the vibration chamber I31 and the vibration chamber II32 through the air outlet I35 and the air outlet II36 respectively; the air outlet I35 and the air outlet II36 are radially staggered; the air outlet I35 and the air outlet II36 are both tapered The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com