Rotary pivot bearing used for driving by shield spiral machine

A shield screw machine, pivot bearing technology, applied in the field of bearings, can solve the problems of complex force at the support, impact force of the drive bearing, uneven pressure of the muck, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

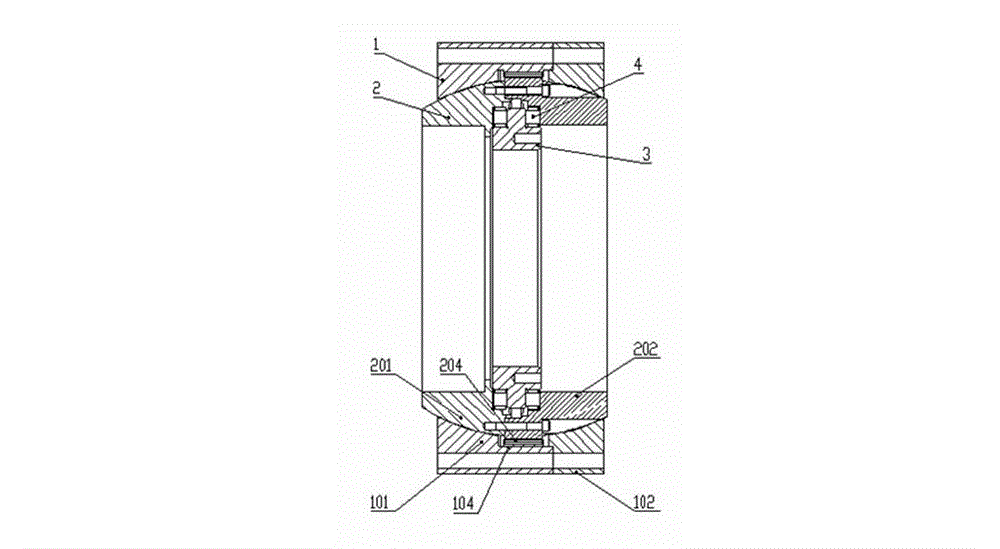

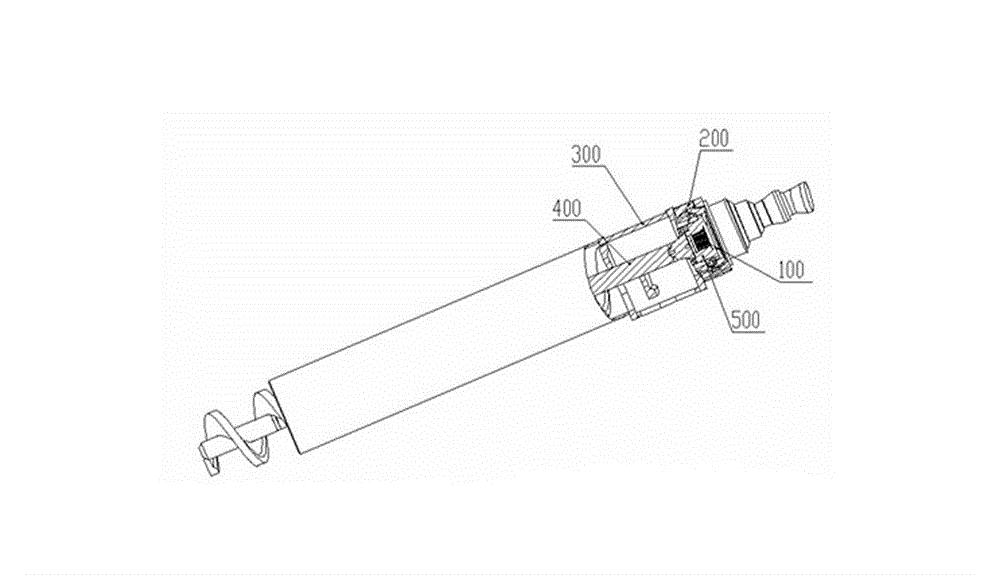

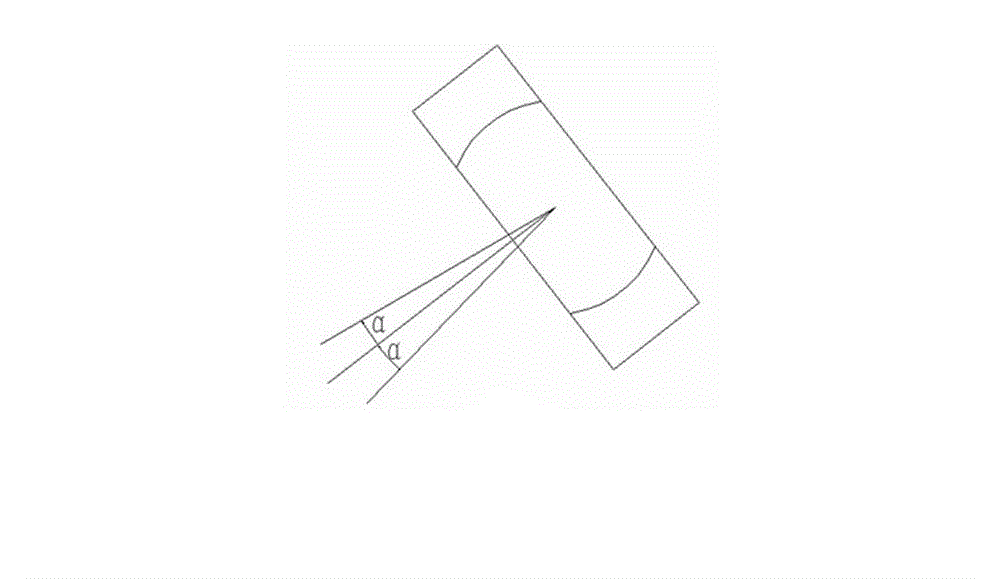

[0017] Embodiment: A rotary pivot bearing for driving a shield screw machine, including an outer ring 1, a middle ring 2, an inner ring 3 and a roller 4, the inner ring 3 can rotate in the circumferential direction and the axial stop is positioned in the middle In the ring 2, there is a raceway for the roller 4 to be accommodated between the inner ring 3 and the middle ring 2. The roller 4 can be rolled and positioned in the raceway, and the middle ring 2 is stopped in the circumferential direction and can rotate in the axial direction. The setting angle α is inserted in the outer ring 1. During operation, the rotating pivot bearing 200 is fixed on the casing 300 of the screw machine, and the inner ring 33 is respectively connected to the screw rod 400 and the output end 100 of the screw machine motor reducer through the connecting flange 500. In this way, the output end of the motor reducer drives the connecting flange 500, the inner ring 33 and the screw rod 400 to rotate aro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com