Multi-nozzle steam jet type heat pump and operation method

A technology of jet heat pump and operation method, which is applied in the field of multi-nozzle steam jet heat pump and operation, can solve the problems that steam cannot be used to drive steam, the pressure range of driving steam is narrow, and production efficiency is reduced, so as to reduce operating cost and facilitate manufacturing , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

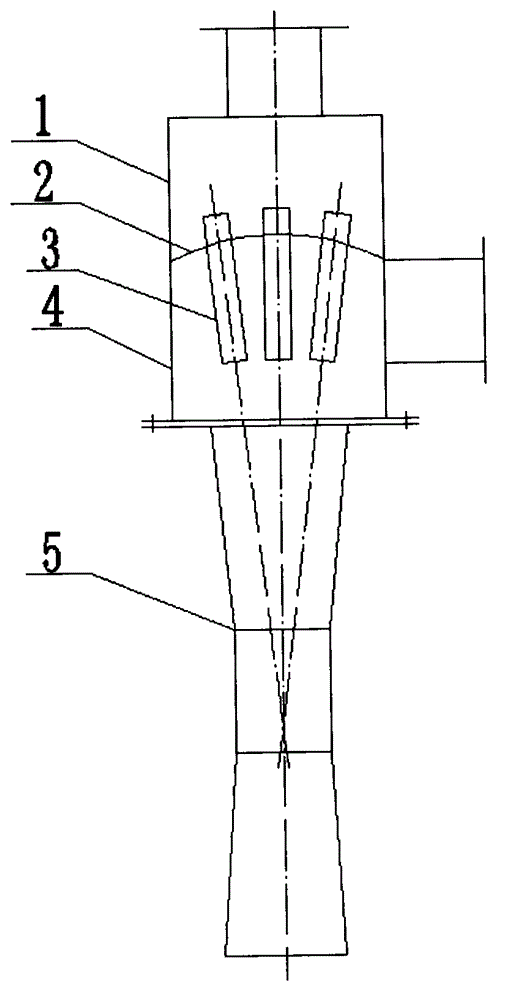

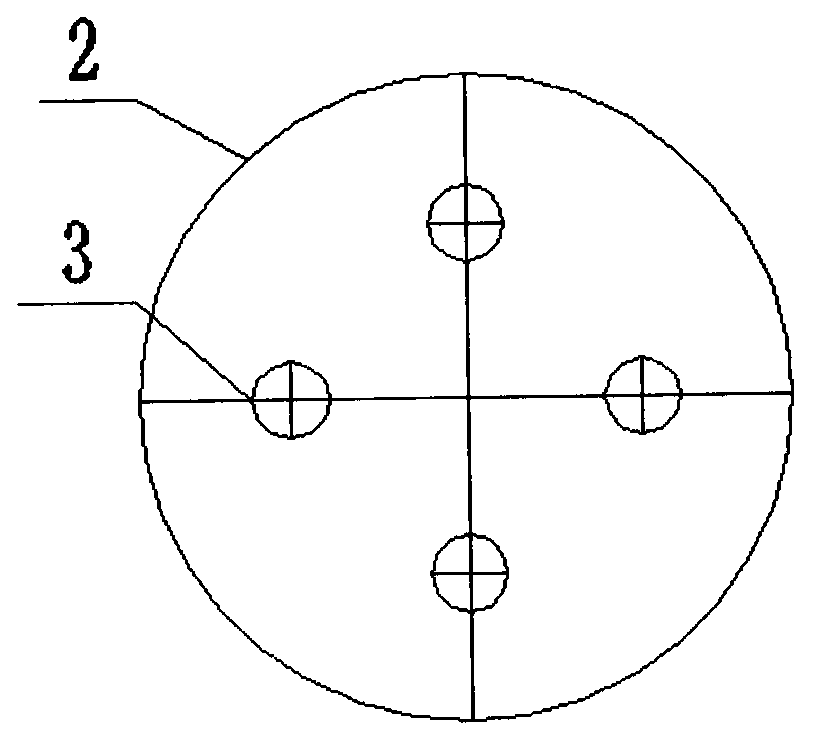

[0017] The present invention will be further described below in conjunction with the accompanying drawings. as attached figure 1 As shown, the high-pressure driven steam suction chamber 1 is located on the upper part of the nozzle fixing plate, coaxial with the symmetrical axis of the nozzle, and communicated with the nozzle. There is a high-pressure steam inlet on the top of the high-pressure driving steam suction chamber 1, which communicates with the high-pressure steam system through a pipeline, and the high-pressure driving steam enters the driving steam suction chamber 1 through the high-pressure steam pipeline. The nozzle fixing plate 2 is a circular plate with a certain radian, and is located in the high-pressure driving steam suction chamber. attached figure 2 The four nozzles of the multi-nozzle group 3 are evenly distributed on the nozzle fixing plate 2, and all form an included angle with the heat pump axis, and spray toward a collection point, and the included ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com