Main steam pressure change-based thermal power generating unit load control method

A technology of main steam pressure and thermal power unit, which is applied in the direction of mechanical equipment, engine components, engine starting, etc. It can solve the problems of large adjustment, insufficient load response range, and difficulty in taking into account the ability of load peak regulation and frequency regulation, etc., to ensure rapidity and Accuracy, meeting the needs of FM peak shaving, and the effect of improving FM capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0034]At present, power grids in some areas of my country require that grid-connected generating units must have the primary frequency regulation function, and thermal power units of 200MW and above should have the AGC function. The primary frequency regulation and AGC operation have been included in the daily assessment.

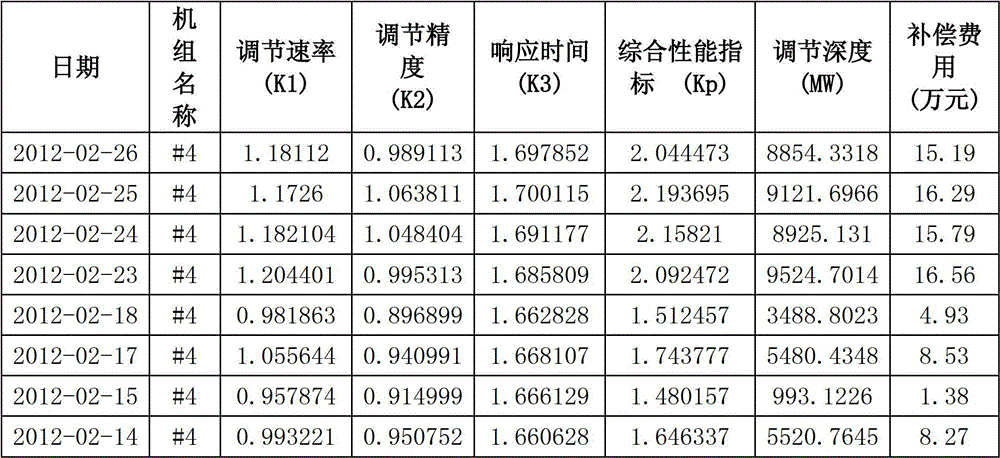

[0035] The test of the selected unit was carried out under the CCS+DEH mode, and the scheme proposed in this paper was adopted. The test object is a subcritical unit with a rated output of 330MW, high and medium pressure combined cylinders, intermediate reheating double-cylinder double-exhaust condensing steam turbines, and the rated pressure of the unit design is 16.5Mpa.

[0036] The main control output value of the steam turbine of this unit is per unit value (0~100%), the range of the given load of the unit and the actual power value of the unit is 0~330MW, and the test records are as follows:

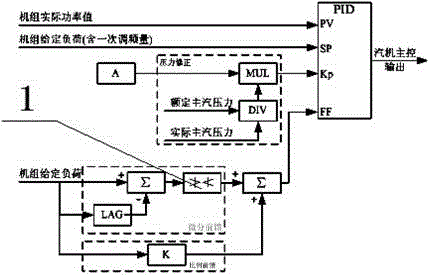

[0037] (1) Ratio feed-forward of the main control of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com