Fiber reinforce plastic (FRP) combination structure frame where integral type node is adopted and construction method thereof

A combined structure and integral technology, applied in building construction, building material processing, construction, etc., can solve the problems of unguaranteed joint strength and difficulty in adding steel prestressed tendons, so as to increase construction flexibility and improve bearing capacity. Force and stiffness, the effect of avoiding the use of formwork

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

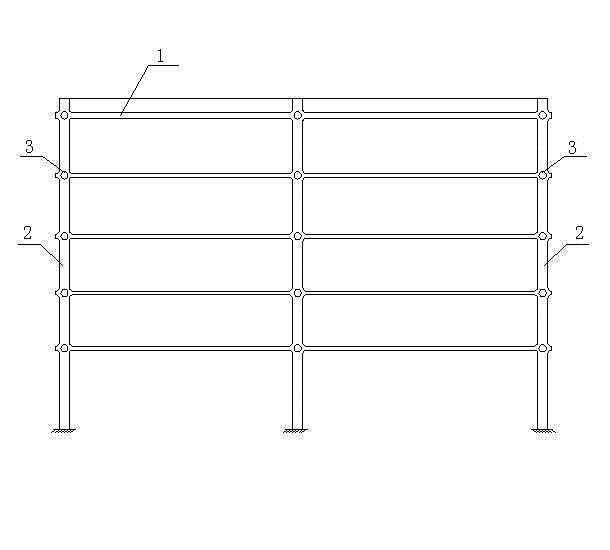

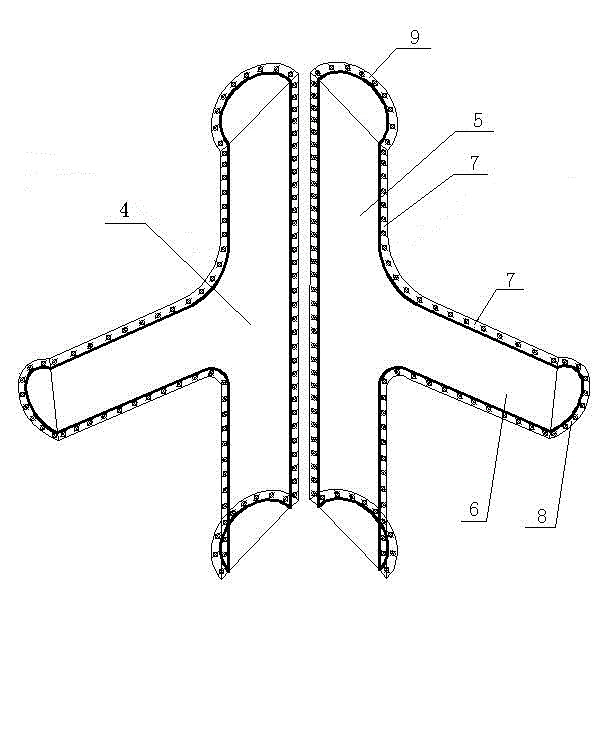

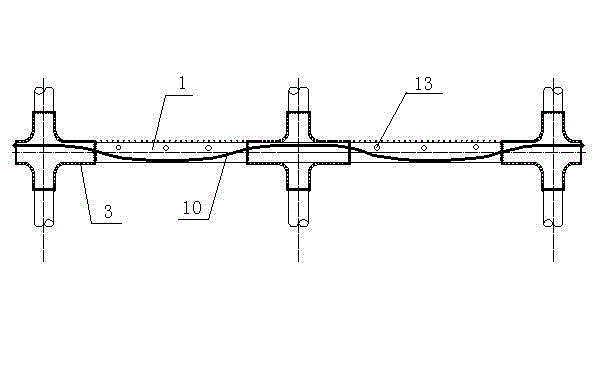

[0030] like figure 1 As shown, the FRP composite structural frame with integral joints is composed of FRP concrete-tube composite beams 1 and FRP concrete-pipe composite columns 2. The two are fixedly connected by the integral node 3 at the intersection, the FRP concrete tube composite column 2 is composed of FRP tube filled with concrete, the FRP tube concrete composite beam 1 is composed of FRP tube filled with concrete, and the FRP tube concrete composite beam 1 has a shear resistance key to facilitate connection to the floor; see figure 2 , the FRP integral node 3 is fastened together by two node monomers 4 and then fixedly connected by bolts. Each node monomer 4 is formed by the intersection of a vertical half-pipe 5 and a horizontal half-pipe 6. The vertical half-pipe 5 The two longitudinal end surfaces of the vertical half-pipe 5 respectively extend outwards to form connecting ears 7, and there are bolt holes on the connecting ears 7, and the upper and lower two ends ...

Embodiment 2

[0032] like Image 6 As shown, in this embodiment, the FRP tube concrete composite column 2 is provided with a cross-shaped steel 12, and the cross-shaped steel 12 passes through the vertical pipe of the integral node 3; the FRP tube concrete composite beam 1 is provided with an H-shaped steel 11, and the H-shaped steel 11 passes through the transverse pipe of the integral node 3, and the FRP pipe of the composite beam 1 is provided with a concrete exhaust port 13. like Figure 7 shown. Other structures are the same as in Embodiment 1.

[0033] The construction method of this embodiment:

[0034]Position the cross-shaped steel 12 in the composite column on the ground floor, bind the steel bars, put the FRP pipe with a high design height on the outside of the two, and then pour concrete into the pipe. The FRP pipe can not only share the load with the steel concrete, but also serve as a formwork when pouring concrete role. At this time, the cross-shaped steel should be high...

Embodiment 3

[0037] Since the integral node 3 in this implementation is formed by buckling two node monomers 4, the FRP tube concrete composite beam 1 is provided with prestressed tendons 10, such as image 3 As shown, the prestressed tendon 10 passes through the transverse pipe of the integral node 3. During construction, the two node monomers 4 are buckled outside the prestressed tendon 10, so that the prestressed tendon 10 can be realized from the integral node 3 in the transverse direction. Through the pipe, the connection at the node is more stable, and the node is stronger. Other structures are the same as in Embodiment 2.

[0038] The construction method of this embodiment:

[0039] Position the cross-shaped steel 12 in the composite column 2 on the ground floor, bind the steel bars, put the FRP pipe with a high design height on the two, and then pour concrete into the pipe. The role of the template. At this time, the cross-shaped steel 12 will be higher than the node of the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com