Device and method for controlling flow reactor used for processing lignocellulose biomass

A lignocellulose and biomass technology, applied in fiber raw material processing, digester, textile and paper making, etc., can solve problems such as difficulty in observing plug tightness, pressure release danger, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Hereinafter, various embodiments will be described with reference to the accompanying drawings. However, the invention is not limited to the shown implementations, but the presented solutions are examples of possible implementations. Features of various implementations may also be combined if these are not expressly conflicting or substitutable with respect to their technical implementation.

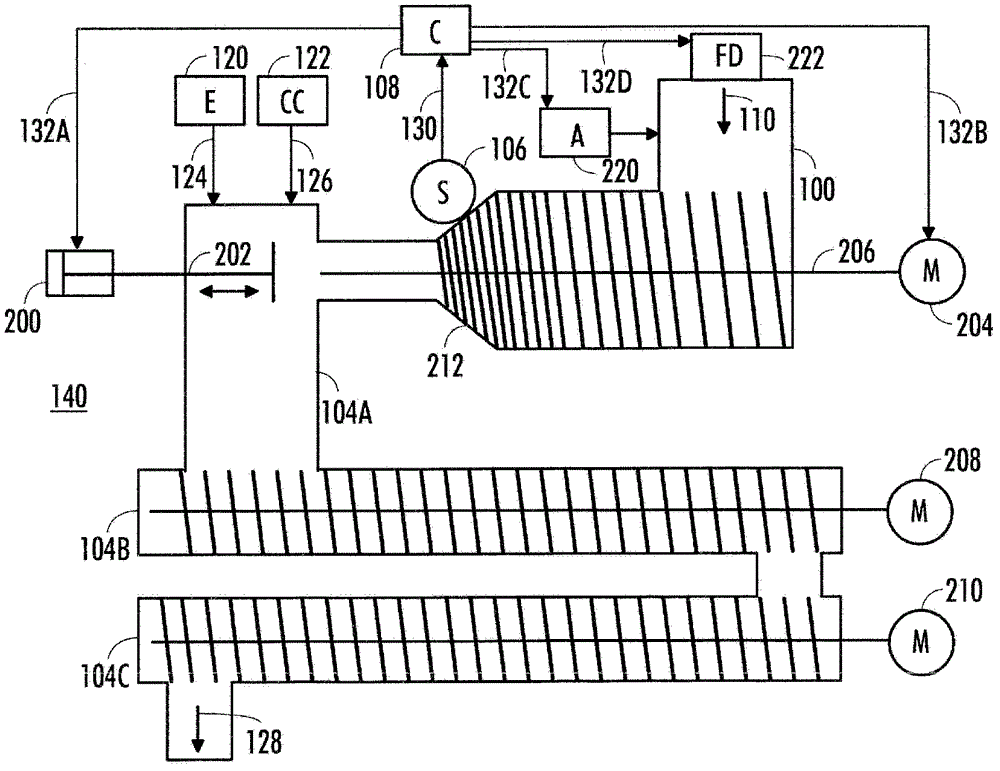

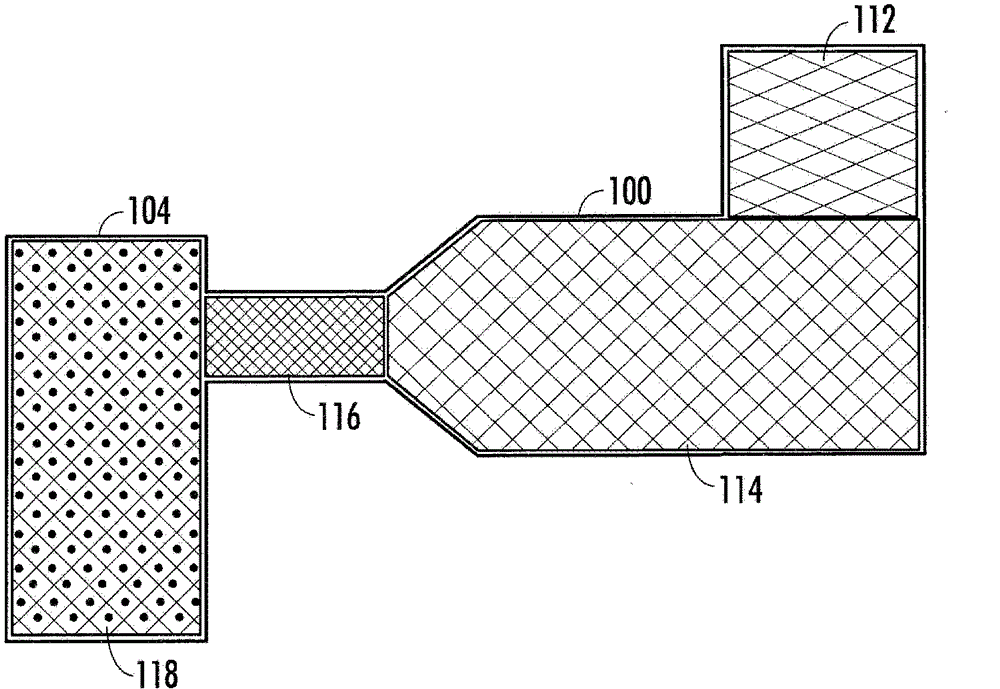

[0014] figure 1 An embodiment of device 140 is shown. figure 1 Only some elements are shown and the implementation of these elements may deviate from what is shown in the figures. Therefore, it should be understood that the device may also include other components. However, such other components may be irrelevant with respect to the actual invention, and therefore it is not necessary to discuss this other component in more detail here. Furthermore, it should be noted that although elements are described as being separate, some elements may be integrated into one physical eleme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com