Bainite sheet steel produced by controlled rolling and cooling method and preparation method thereof

A technology of controlled rolling, controlled cooling, and bainite, applied in metal rolling, metal rolling, rolling mill control devices, etc., can solve problems such as difficult process control, and achieve high production efficiency, simple and controllable production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

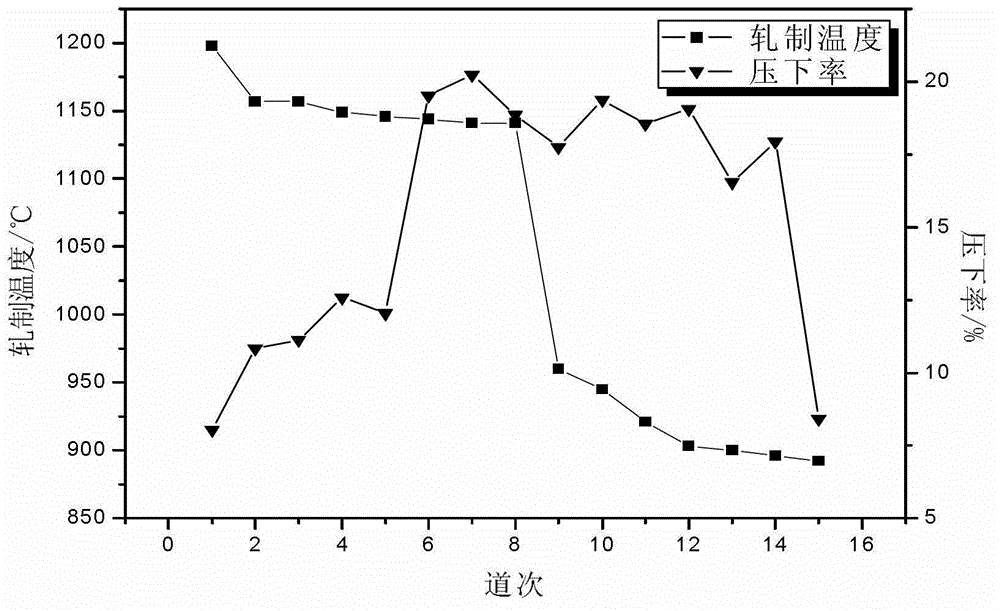

Embodiment 1

[0030] The bainite thin steel plate produced by controlled rolling and controlled cooling technology has a thickness of 10 mm and a width of 3800 mm. The chemical composition is shown in Table 1 in terms of weight percentage, specifically: C: 0.05%, Si: 0.39%, Mn: 1.68% , P: 0.013%, S: 0.004%, Nb+Ti: 0.07%, Mo+Cr: 0.35%, Als: 0.035%, the rest is Fe and trace impurity elements, and C+Si / 30+(Mn+Cr) / 20+Mo / 15 (abbreviated as Pcm in Table 1) <0.25;

[0031] The specific preparation method is as follows:

[0032] (1) According to the predetermined composition, see Table 1, it is smelted on a 130t converter production line, and cast into a continuous casting slab with a specification of 250mm×1600mm×L.

[0033] example C Si mn P S Cr+Mo Nb+ Ti als Pcm 1 0.05 0.39 1.68 0.013 0.004 0.35 0.07 0.035 <0.25 2 0.02 0.50 1.70 0.012 0.005 0.40 0.08 0.030 <0.25 3 0.08 0.35 1.65 0.012 0.004 0.32 0.05 0.015 <0.25 4 0.06 0.40...

Embodiment 2-4

[0045] With reference to the method of Example 1, each bainite thin steel plate is prepared correspondingly according to the component content design and process conditions in Table 1-Table 3, wherein: the rolling of the steel plate on the roller table in the residual heat self-tempering in the embodiment 2-4 The time is 80s, 90s, and 120s respectively. The chemical composition content of the bainite thin steel plate prepared by this method is shown in Table 1, and the test results of the unevenness and mechanical properties of the steel plate are shown in Table 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com