Flexible one-step silane naturally-crosslinked EPDM cable material and preparation method thereof

A technology of natural cross-linking and method silane, which is applied in the field of wire and cable insulation and sheath materials, soft one-step silane natural cross-linking EPDM cable material and its preparation, which can solve the problem of product instability, high energy consumption and short storage period To achieve reliable extrusion performance and cross-linking degree, simplify the process flow, and stabilize product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

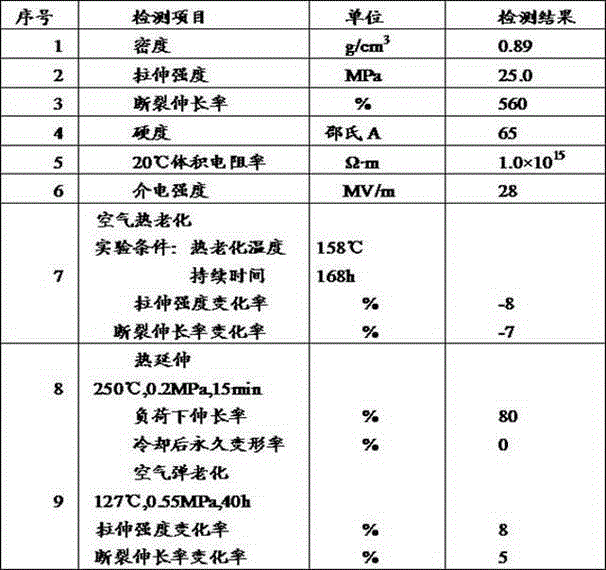

[0045] Example 1: Soft one-step silane natural crosslinking EPDM cable material and its preparation method

[0046] One, the preparation of EPDM compound:

[0047] Weigh 70 parts of EPDM (Exxon 2605B) and 30 parts of ethylene-ethyl acrylate copolymer (DuPont 2116), and mix them evenly to obtain the EPDM compound.

[0048] 2. Preparation of catalyst masterbatch:

[0049]Weigh 100 parts of low-density polyethylene (Shanghai Petrochemical Q281), 15 parts of catalyst (di-n-butyltin maleate), 15 parts of antioxidant (antioxidant 1010), metal deactivator (N,N'-bis[ β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionyl]hydrazine) 10 parts, lubricant (stearic acid) 10 parts, after mixing in a closed high-speed mixer for 20 minutes, in ordinary Extrude and granulate on a twin-screw extruder, dry at 60°C for two hours, and set aside.

[0050] Three, the preparation of cross-linking composite agent:

[0051] Weigh 2 parts of vinyltrimethoxysilane as a coupling agent and 1 part of dicumyl pe...

Embodiment 2 4

[0057] Embodiments 2-4: A kind of flexible one-step silane natural crosslinking EPDM cable material and its preparation method

[0058] 1. The formula of EPDM compound is as follows:

[0059] EPDM EEA Embodiment two 50 copies 50 copies Embodiment Three 60 copies 40 copies Embodiment Four 80 copies 20 copies

[0060] 2. The formula of the catalyst masterbatch is as follows:

[0061] LDPE catalyst antioxidant metal deactivator lubricant Embodiment two 100 copies 4 parts 15 copies 3 copies 13 copies Embodiment Three 100 copies 20 copies 20 copies 5 copies 20 copies Embodiment Four 100 copies 10 copies 5 copies 8 servings 30 copies

[0062] Note: 1. Example 2: Catalyst: 2 parts of di-n-butyltin dilaurate, 2 parts of di-n-octyltin dilaurate; antioxidant: 15 parts of dilauryl thiodipropionate; metal deactivator N, N 3 parts of '-bis[β-(3,5-di-tert-butyl-4-hydroxypheny...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com