Composite phosphor luminescent glass and preparation method for same

A technology of luminescent glass and fluorescent powder, which is applied in the field of luminescent materials and its preparation, can solve the problems of unretrieved composite phosphor luminescent glass patents, etc., achieve good luminous performance and chemical stability, easy industrialization, and solve the problems of resin aging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

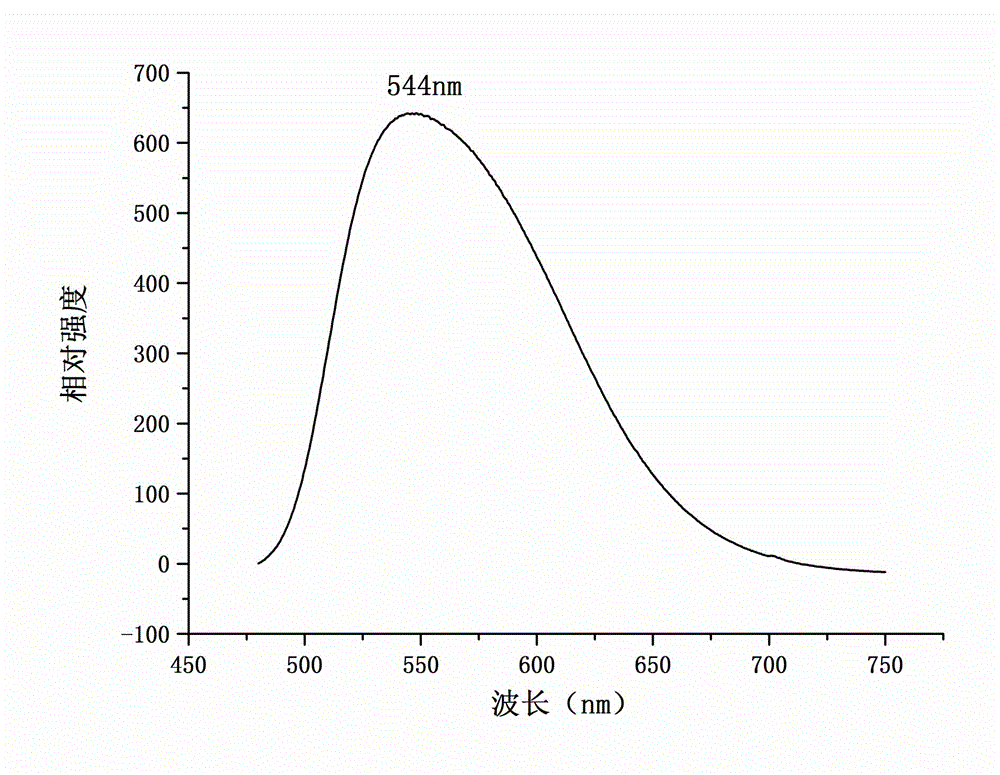

Image

Examples

Embodiment 1

[0034] The components of the composite phosphor luminescent glass include: phosphorus-zinc-silicon system glass powder and Y 3 al 5 o 12 : Ce 3+ Phosphor powder, their mass percentages are: phosphorus-zinc-silicon system glass powder 80%; Y 3 al 5 o 12 : Ce 3+ Phosphor 20%.

[0035] Among them, the composition of phosphorus-zinc-silicon glass includes P 2 o 5 , ZnO, SiO 2 、Al 2 o 3 and Na 2 O, the mass percentage of each component is: P 2 o 5 : 50%, ZnO: 40%, SiO 2 : 5%, Al 2 o 3 : 2.5%, Na 2 O: 2.5%.

[0036] Concrete preparation process is as follows:

[0037] (1) Preparation of phosphorus-zinc-silicon system glass:

[0038] ① Weigh NH according to the formula 4 h 2 PO 3 , ZnO, SiO 2 、Al 2 o 3 and Na 2 CO 3 Analysis of pure raw materials, where P 2 o 5 by NH 4 h 2 PO 3 Introduce, Na 2 O by Na 2 CO 3 introduce;

[0039] ② NH to be weighed 4 h 2 PO 3 , ZnO, SiO 2 、Al 2 o 3 、Na 2 CO 3 The raw materials were fully ground in an agate ...

Embodiment 2

[0047] The components of the composite phosphor luminescent glass include: phosphorus-zinc-silicon system glass powder and Y 3 al 5 o 12 : Ce 3+ Phosphor powder, their mass percentages are: phosphorus-zinc-silicon system glass powder 80%; Y 3 al 5 o 12 : Ce 3+ Phosphor 20%.

[0048] Among them, the composition of phosphorus-zinc-silicon glass includes P 2 o 5 , ZnO, SiO 2 、Al 2 o 3 and Na 2 O, the mass percentage of each component is: P 2 o 5 : 55%, ZnO: 35%, SiO 2 : 5%, Al 2 o 3 : 2.5%, Na 2 O: 2.5%.

[0049] Concrete preparation process is as follows:

[0050] (1) Preparation of phosphorus-zinc-silicon system glass:

[0051] ① Weigh NH according to the formula 4 h 2 PO 3 , ZnO, SiO 2 、Al 2 o 3 and Na 2 CO 3 Analysis of pure raw materials, where P 2 o 5 by NH 4 h 2 PO 3 Introduce, Na 2 O by Na 2 CO 3 introduce;

[0052] ② NH to be weighed 4 h 2 PO 3 , ZnO, SiO 2 、Al 2 o 3 、Na 2 CO 3 The raw materials were fully ground in an agate m...

Embodiment 3

[0060] The components of the composite phosphor luminescent glass include: phosphorus-zinc-silicon system glass powder and Y 3 al 5 o 12 : Ce 3+ Phosphor powder, their mass percentages are: phosphorus-zinc-silicon system glass powder 85%; Y 3 al 5 o 12 : Ce 3+ Phosphor 15%.

[0061] Among them, the composition of phosphorus-zinc-silicon glass includes P 2 o 5 , ZnO, SiO 2 、Al 2 o 3 and Li 2 O, the mass percentage of each component is: P 2 o 5 : 45%, ZnO: 40%, SiO 2 : 10%, Al 2 o 3 : 2.5%, Li 2 O: 2.5%.

[0062] Concrete preparation process is as follows:

[0063] (1) Preparation of phosphorus-zinc-silicon system glass:

[0064] ① Weigh NH according to the formula 4 h 2 PO 3 , ZnO, SiO 2 、Al 2 o 3 and Li 2 CO 3 Analysis of pure raw materials, where P 2 o 5 by NH 4 h 2 PO 3 Bring in, Li 2 O by Li 2 CO 3 introduce;

[0065] ② NH to be weighed 4 h 2 PO 3 , ZnO, SiO 2 、Al 2 o 3 , Li 2 CO 3The raw materials were fully ground in an agat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com