Process control method of modified sequencing batch reactor (MSBR) system

A process control and reaction tank technology, applied in aerobic and anaerobic process treatment, anaerobic digestion treatment and other directions, can solve the problems of single mode, unable to adapt to the influence of process flow and effect, etc., to achieve sufficient pre-sedimentation time, exposure The effect of sufficient air time and strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

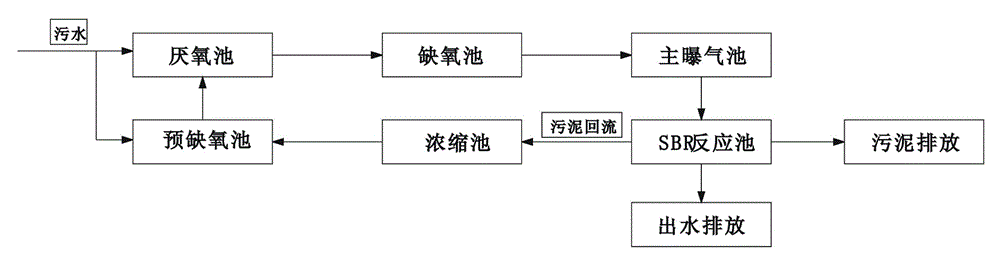

[0046] Process control methods for MSBR systems, such as figure 1 shown, including the following specific steps:

[0047] a. Inject 70% of the collected sewage into the anaerobic tank 4 through the pipeline, and at the same time inject the remaining 30% of the sewage into the pre-anoxic tank 3 for denitrification. The COD value of the sewage is between 200-500mg / L, NH3-N Value between 20-45mg / L; The design load of the process control method of the MSBR system is 20000 tons of sewage / day;

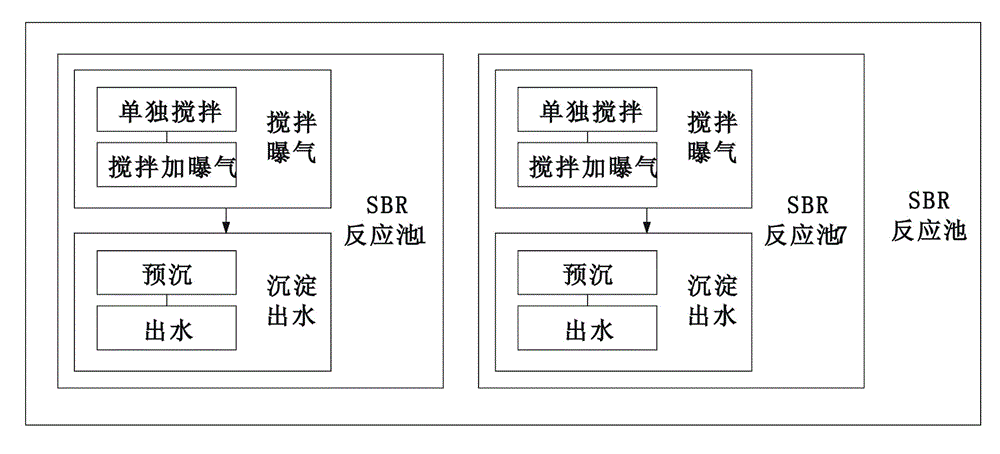

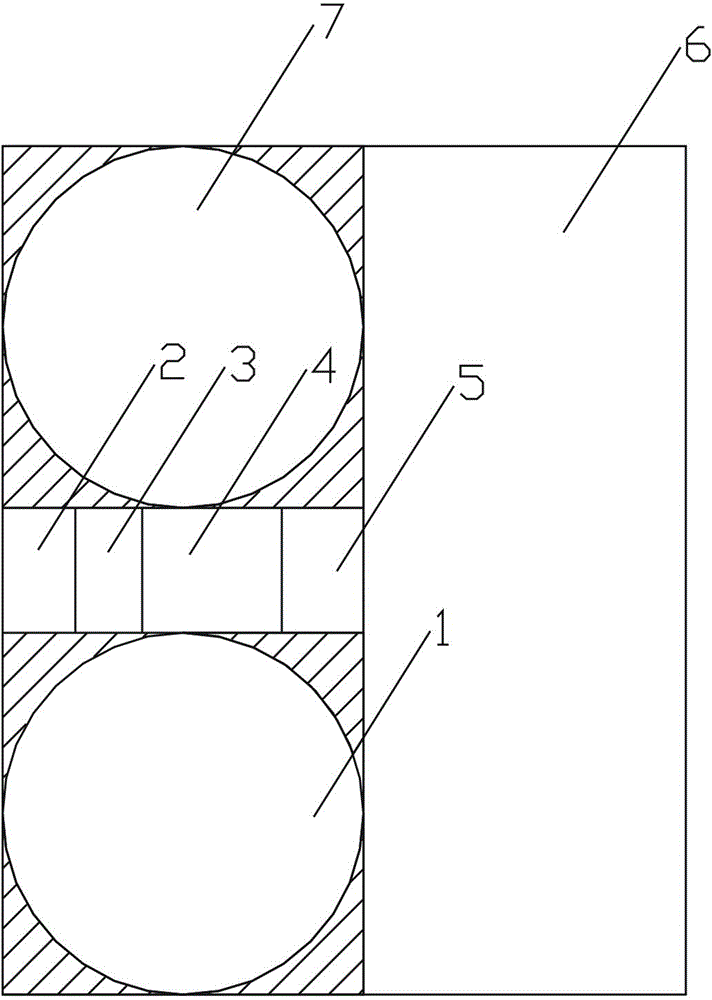

[0048] b. In step a, the effluent of anaerobic tank 4 enters the main aeration tank 6 after passing through the anoxic tank 5, and the effluent of the main aeration tank 6 enters the SBR reaction tank 1, 7, in order to reduce the effluent of the main aeration tank 6 Enter SBR reaction tank 1,7 to the agitation of the sludge layer at the bottom of SBR reaction tank 1,7, and described SBR reaction tank 1,7 is circular, as image 3 As shown, the effluent of the main aeration tank 6 is in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com