Multi-phase flow assembly type sealing coalescence oil removing apparatus

A prefabricated, multi-phase flow technology, which is applied in the direction of grease/oily substance/suspton removal device, liquid separation, flocculation/sedimentation water/sewage treatment, etc. Long residence time and other problems, to achieve the effect of short residence time, convenient sludge discharge and fast separation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

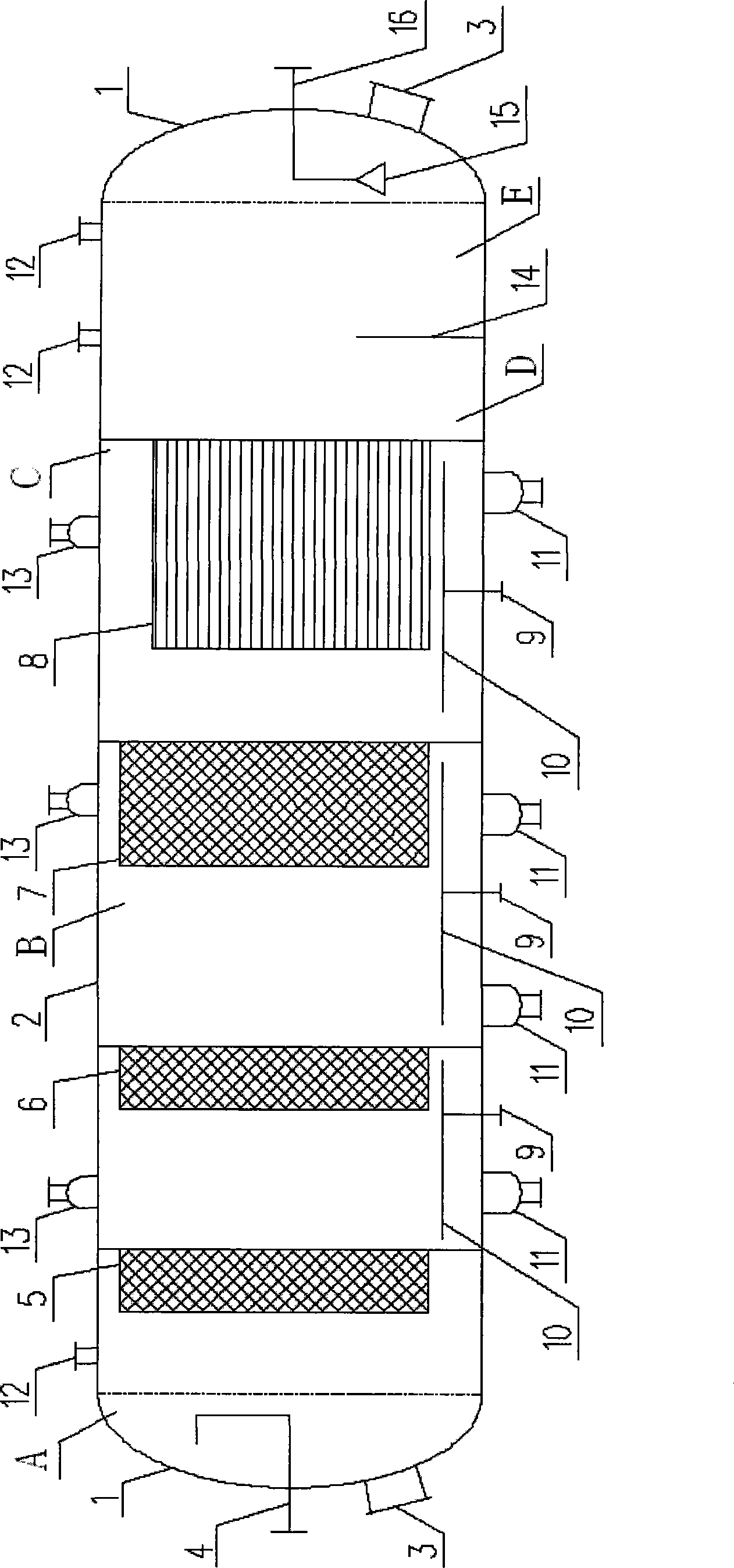

[0015] In order to further disclose the technical solution of the present invention, the following will be described in detail through the embodiments in conjunction with the accompanying drawings:

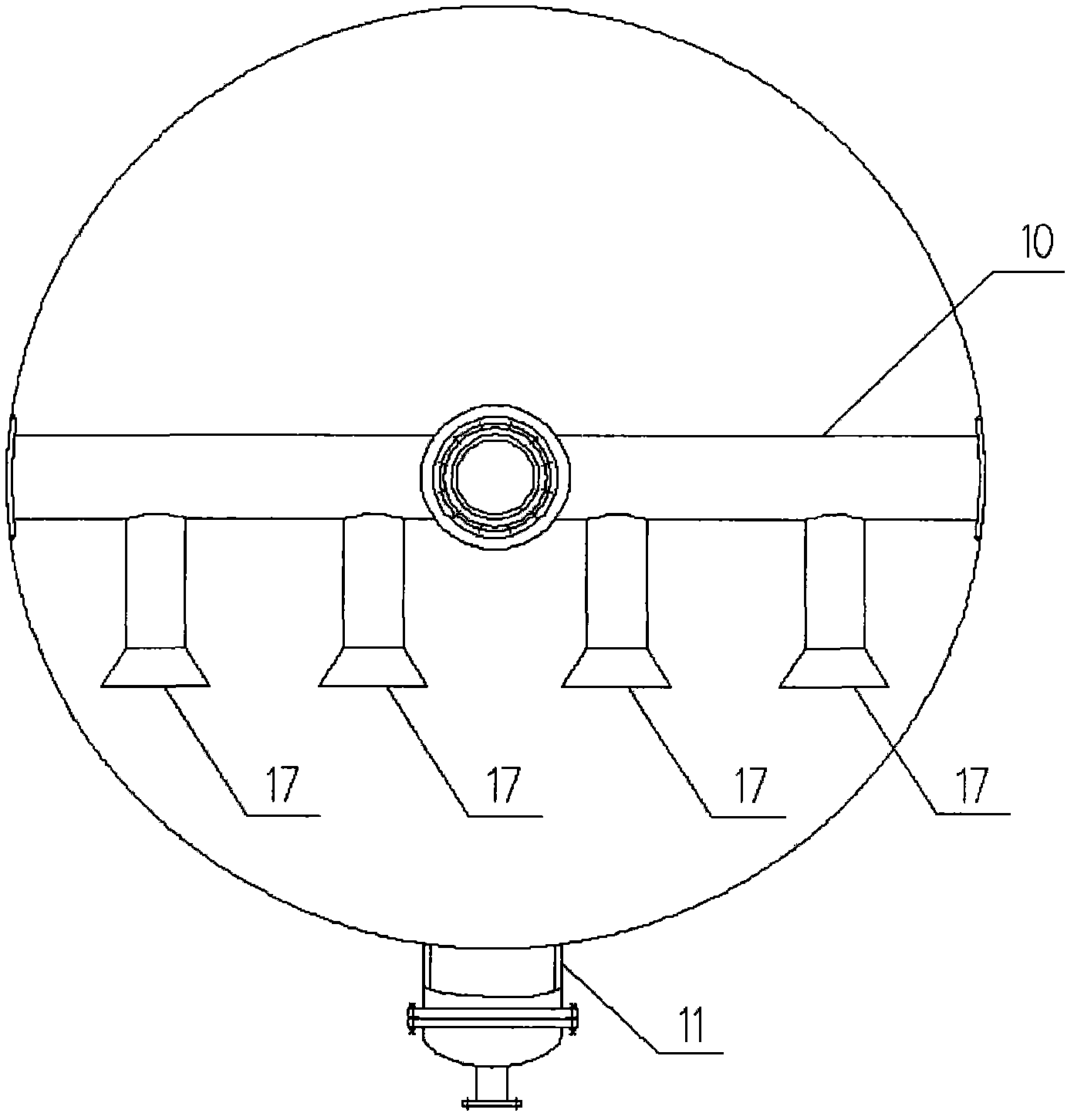

[0016] The water inlet of the multi-phase flow assembled closed coalescing degreasing device enters the water distribution chamber A through the water inlet pipe 4. After the uniform water distribution is completed in the water distribution chamber A, the sewage enters the first-stage coalescence section 5, and passes through the horizontal wave flow coalescing filler. After the coalescence, part of the dispersed oil and emulsified oil in the water coalesce to form large oil droplets, which pass through the primary coalescence section together with the slick oil and then float up, and gather in the upper part of the tank 2. At the same time, part of the sludge It settles here and deposits in the lower part of the tank body; the water passing through the primary coalescing section 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com