Method for producing magnesium sulfate heptahydrate by using desulfurization wastewater

A technology of magnesium sulfate heptahydrate and desulfurization waste liquid, applied in magnesium sulfate and other directions, can solve the problems of high cost, high operation and maintenance cost, complicated operation, etc., and achieve the effect of stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] (1) Modulation of desulfurizer:

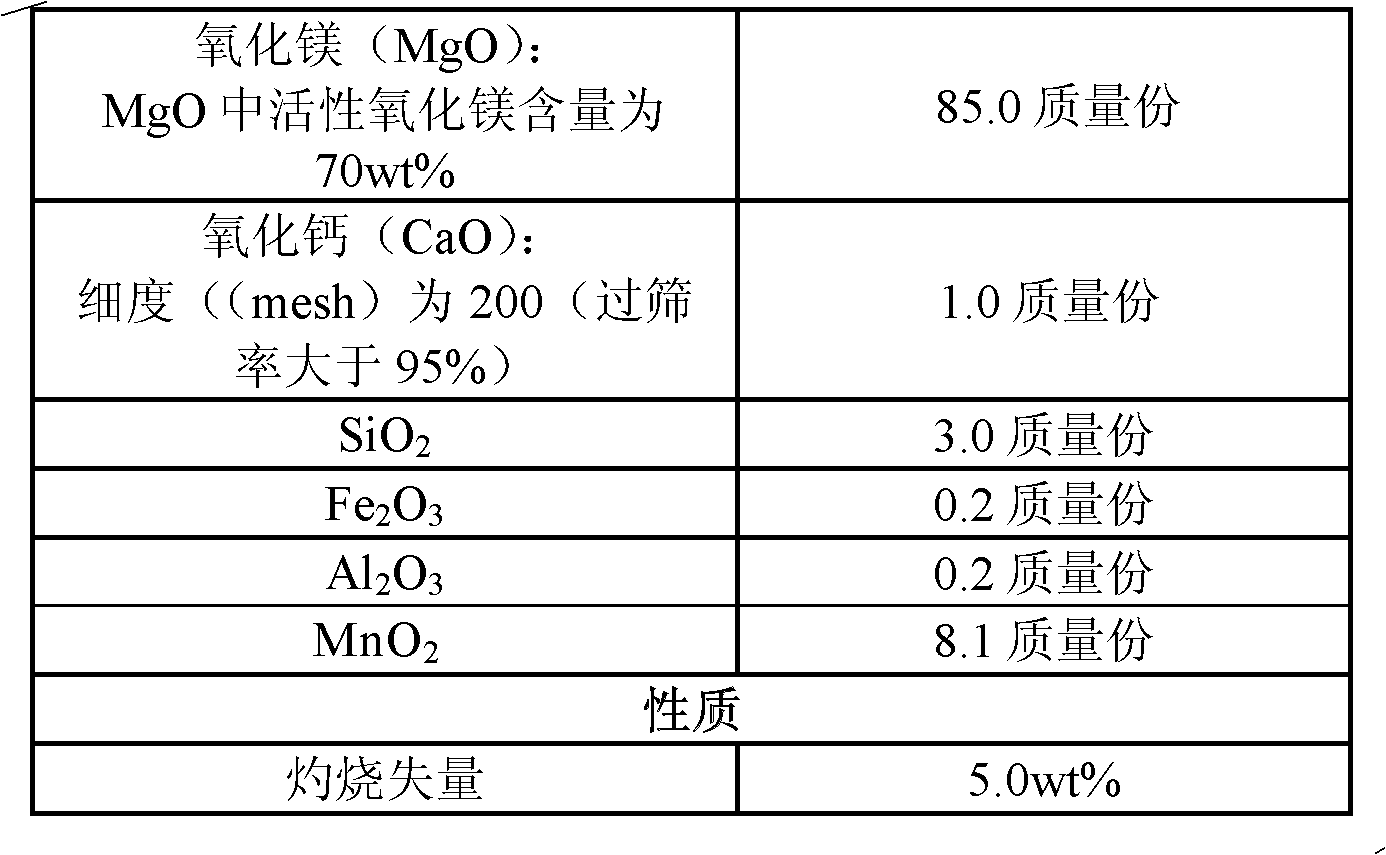

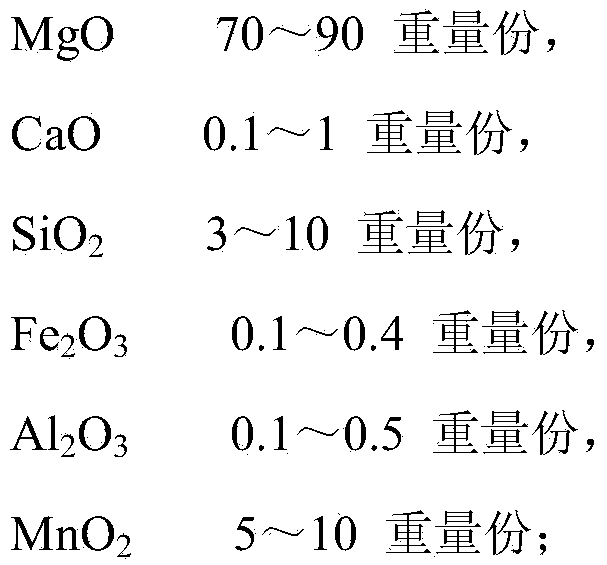

[0064] According to the following formula, mix each component evenly to obtain a desulfurizing agent.

[0065]

[0066] (2) The process of using desulfurization waste liquid to produce magnesium sulfate

[0067] 1. Pulping:

[0068] Add water to the prepared desulfurizer powder, make slurry, and mature to form a slurry containing magnesium hydroxide (abbreviated as slurry containing magnesium hydroxide), and keep it in the slurry tank for later use.

[0069] 2. Desulfurization and oxidation:

[0070] The sulfur dioxide in the flue gas reacts with the slurry containing magnesium hydroxide in the desulfurization tower to remove the SO in the flue gas 2 .

[0071] In the desulfurization tower, the slurry containing magnesium hydroxide contains strong oxidant MnO 2 Make the slurry in the tower generate a solution of 95wt% magnesium sulfate and 5wt% magnesium sulfite from the desulfurization slurry at the moment when the desulfurizat...

Embodiment 2

[0083] In addition to adding 5 parts by weight of KMO to the desulfurizer 4 , except that the desulfurization slurry is generated into a solution of 97wt% magnesium sulfate and 3wt% magnesium sulfite (the percentages are based on the sum of the weight percentages of magnesium sulfate and magnesium sulfite being 100wt%), other conditions are the same as in Example 1 . The properties of the obtained product are shown in Table 2, and the experimental data are shown in Table 3.

Embodiment 3

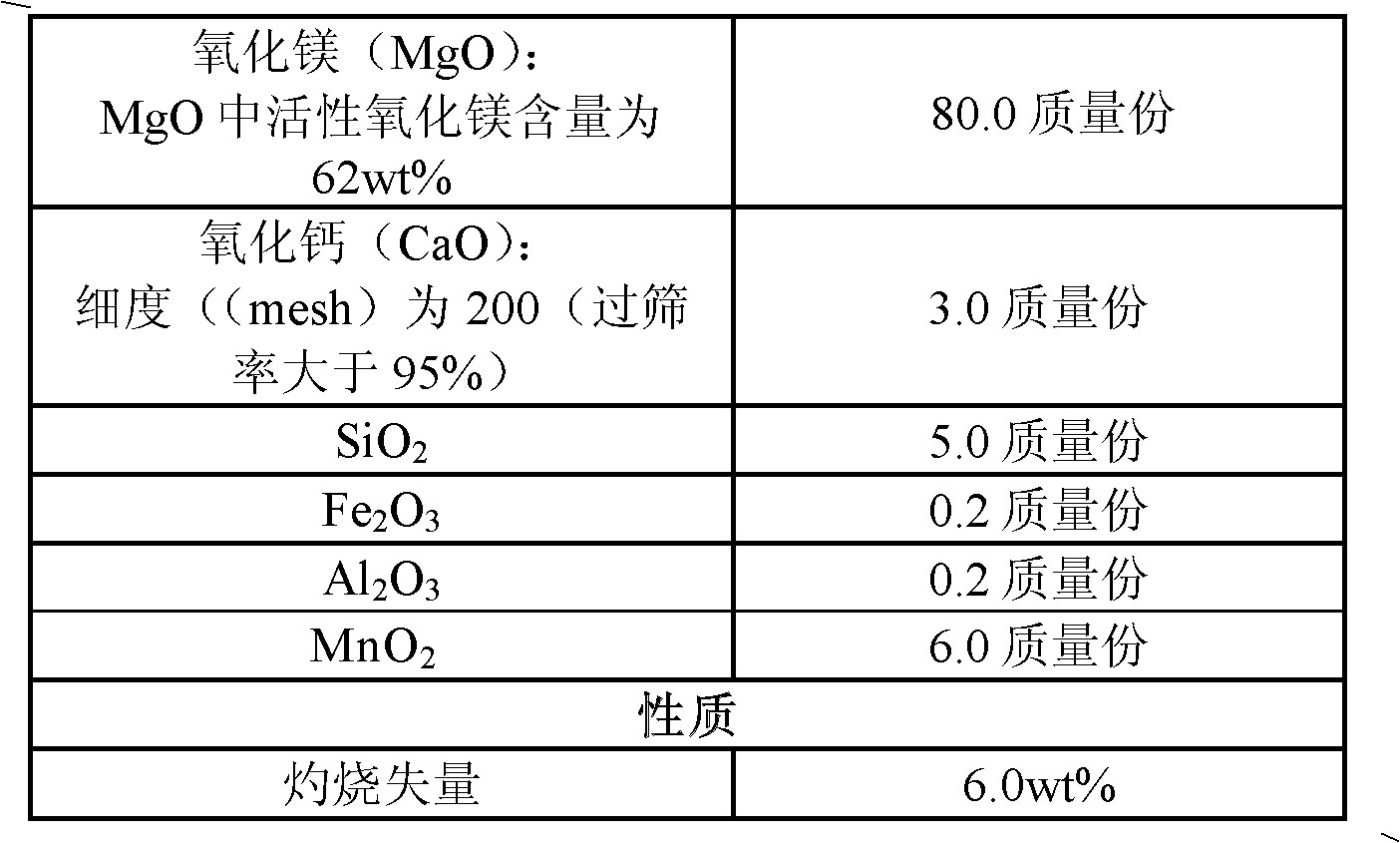

[0085] Except that the weight part of magnesium oxide is changed to 80 parts by weight in the desulfurizer, the desulfurization slurry is generated into a solution of 90wt% magnesium sulfate and 10wt% magnesium sulfite (the percentages are based on the percentage by weight of magnesium sulfate and magnesium sulfite) and are 100wt% meter), other conditions are identical with embodiment 1. The properties of the obtained product are shown in Table 2, and the experimental data are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com