Porous carbon with high-volumetric-specific-capacitance composite graphene, preparation method thereof, and application thereof

A technology of composite graphene and porous carbon, applied in the field of porous carbon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

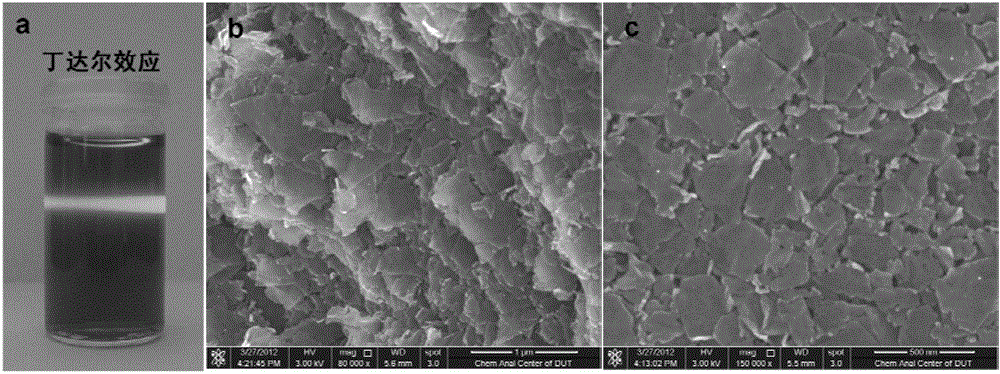

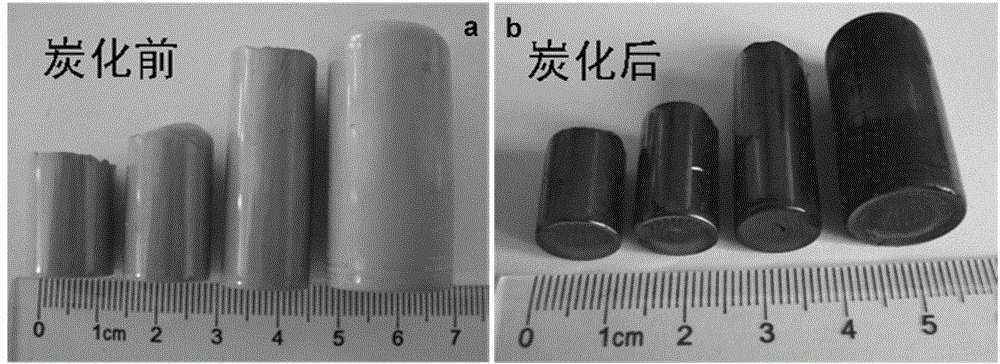

[0069] Firstly, a resorcinol aqueous solution with a mass concentration of 0.1 g / ml and a lysine aqueous solution with a mass concentration of 3.3 mg / ml were prepared. At 25°C, add 15ml of lysine aqueous solution to 200ml, 0.5mg / ml graphene oxide aqueous solution to obtain a clear, transparent light yellow solution, then add 10ml of resorcinol aqueous solution to the above solution, and stir for 10min , to obtain a transparent bright yellow solution; then, under stirring conditions, inject 1.47g of formaldehyde aqueous solution (37wt%) into the above solution, and the color of the solution is deepened; Rotate / min centrifugation, obtain polymer-embedded graphene oxide interlayer composite; After drying at 50 DEG C for 24 hours, use inert gas protection to rise to 400 DEG C from room temperature with 3 DEG C / min, constant temperature 60min, again with 3 DEG C The heating rate of °C / min was raised from 400 °C to the final carbonization temperature of 800 °C, and the temperature w...

Embodiment 2

[0071]First, a resorcinol aqueous solution with a mass concentration of 0.1 g / ml, a 3.3 mg / ml lysine aqueous solution and a 91 mg / ml F127 solution were prepared. At 25°C, add 15ml of lysine aqueous solution to 200ml, 0.5mg / ml graphene oxide aqueous solution to obtain a clear, transparent light yellow solution, then add 10ml of resorcinol aqueous solution to the above solution, and stir 10min, a transparent bright yellow solution was obtained; under stirring conditions, 1ml of F127 ethanol aqueous solution (the ratio of ethanol to water was 1:1) was added to the above transparent bright yellow solution, and stirred for 20min; 1.47g of formaldehyde aqueous solution (37wt% ) into the above solution quickly, and the color of the solution deepened; transferred to a hydrothermal kettle, hydrothermally reacted at 120°C for 8 hours, after cooling, centrifuged at 14,000 rpm to obtain a sample, dried at 50°C for 24 hours, and protected with an inert gas Rise from room temperature to 400...

Embodiment 3

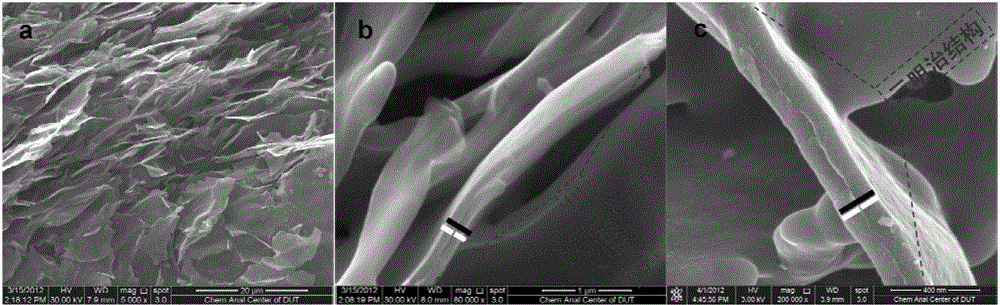

[0073] First, a resorcinol aqueous solution with a mass concentration of 0.5 g / ml and an asparagine aqueous solution with a mass concentration of 0.23 g / ml were prepared. At 25°C, add 2ml of asparagine aqueous solution to 20ml, 5mg / ml graphene oxide aqueous solution to obtain an orange transparent solution, then add 10ml of resorcinol aqueous solution to the above solution, stir for 15min, and obtain a brown transparent solution. solution; then under stirring conditions, 7.35g formaldehyde aqueous solution (37wt%) was quickly injected into the above solution, and the solution changed from a brown transparent solution to a dark gray transparent solution; transferred to an oven at 90°C for gel aging for 4h; after 50 After drying at °C for 24 hours, use an inert gas protection to rise from room temperature to 400°C at a rate of 3°C / min, and dry at a constant temperature for 60 minutes; C, keep the temperature for 120min, and get the "sandwich structure" nano carbon sheet self-ass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Volume specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com