Serpentine mechanical arm

A mechanical arm and snake-shaped technology, applied in the direction of manipulators, claw arms, joints, etc., can solve the problems of complex structure of the linkage mechanism, difficult bending of the mechanical arm, difficulty in adapting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

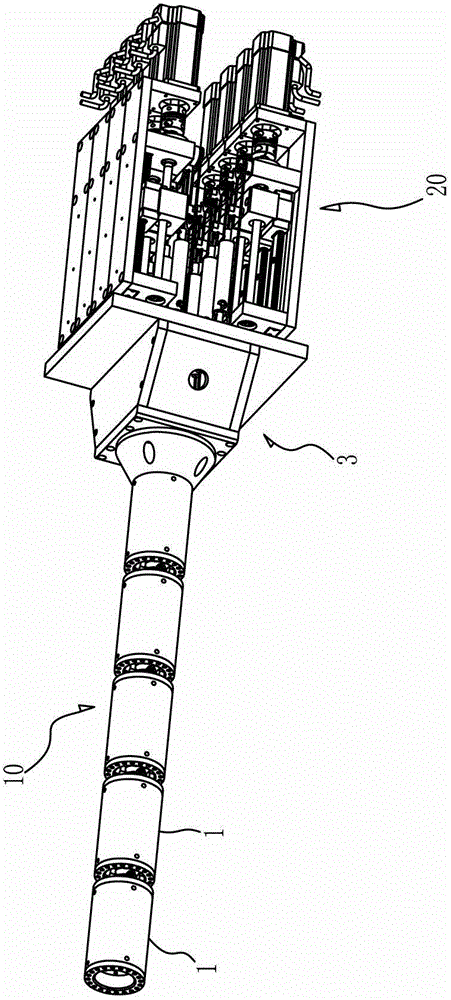

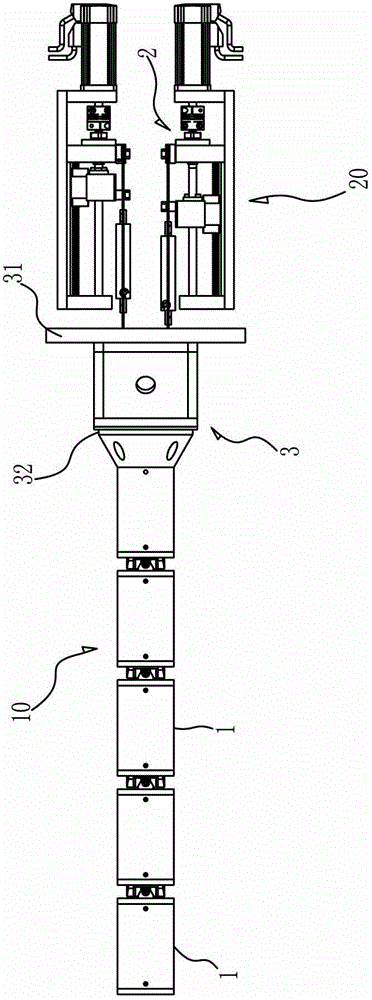

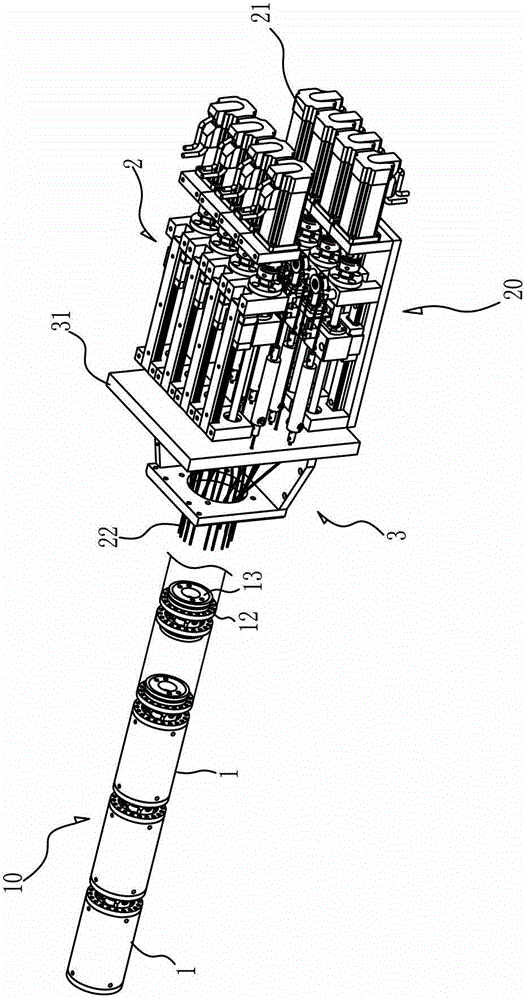

[0029] See Figure 1-9 As shown, the present invention is a serpentine mechanical arm, which consists of an arm body 10, a driving part 20 and a connecting part 3, wherein the connecting part 3 is located between the arm body 10 and the driving part 20, and the driving part 20 is fixedly connected to the rear end of the connection part 3 , and the arm body 10 is connected to the front end of the connection part 3 . The arm body 10 is driven by the driving part 20 to realize bending and swinging.

[0030] See figure 1 , 2 , 3, the arm body 10 is formed by a plurality of joints 1 connected to each other. In this embodiment, five joints are used, and two adjacent joints 1 can have two degrees of freedom in the up, down and left and right directions. The first joint is directly fixedly connected to the connecting part 3, and the last joint is used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com