Paracetamol effervescent granule and identification method thereof

A technology of acetaminophen and effervescent granules, applied in the direction of anhydride/acid/halide active ingredients, etc., can solve the problem that acid and alkali agents cannot be mixed with drugs and other excipients at the same time, and the drug efficacy cannot be well exerted. , unfavorable large-scale production operations and other problems, to achieve the effect of being suitable for industrial production, improving identification items, and good compliance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Pass acetaminophen, citric acid, fumaric acid, and sodium bicarbonate through an 80-mesh sieve respectively, and crush sucrose and pass through an 80-mesh sieve for later use.

[0047] Ethanol solution of polyethylene glycol: Weigh 40ml polyethylene glycol 400, appropriate amount of ethanol, dissolve polyethylene glycol in ethanol, stir evenly to obtain polyethylene glycol ethanol solution.

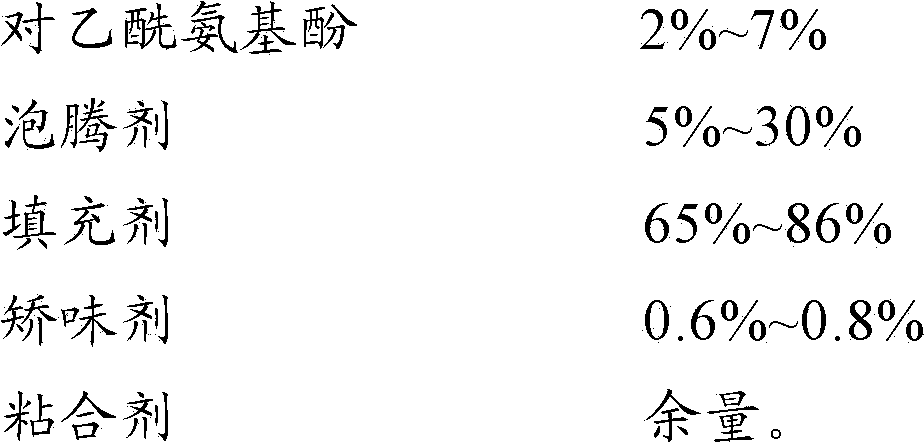

[0048] Weigh the raw materials of the following prescription quantities:

[0049]

[0050] 1) Mix 100g of paracetamol, 16g of citric acid, 24g of fumaric acid, 68g of sodium bicarbonate, 1785g of sucrose, and 15g of stevioside, add 80g of polyethylene glycol ethanol solution to make a soft material, and sieve For wet granules, put the wet granules evenly into an oven at 55°C, dry for 1 hour, and granulate to obtain dry granules for later use.

[0051] 2) Put the dry granules of step 1) in a mixer, mix for ten minutes, detect the intermediate, and pack it separately.

Embodiment 2

[0053] Pass acetaminophen, citric acid, fumaric acid, and sodium bicarbonate through an 80-mesh sieve respectively, and crush sucrose and pass through an 80-mesh sieve for later use.

[0054] The preparation of polyethylene glycol solution in ethanol is the same as in Example 1.

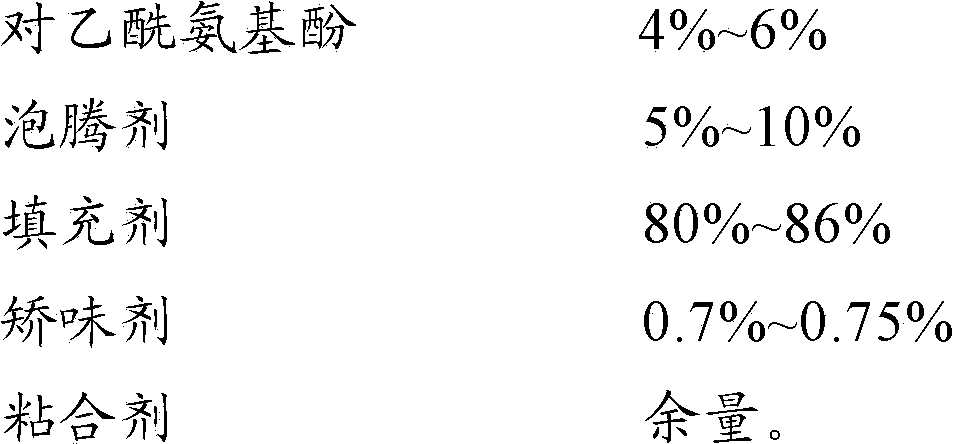

[0055] Weigh the raw materials of the following prescription quantities:

[0056]

[0057]

[0058] 1) Mix 500g of paracetamol, 80g of citric acid, 120g of fumaric acid, 340g of sodium bicarbonate, 8925g of sucrose, and 75g of stevioside, add 395g of polyethylene glycol ethanol solution to make a soft material, and sieve For wet granules, put the wet granules evenly into an oven at 55°C, dry for 1 hour, and granulate to obtain dry granules for later use.

[0059] 2) Put the dry granules of step 1) in a mixer, mix for ten minutes, detect the intermediate, and pack it separately.

Embodiment 3

[0061] Pass acetaminophen, citric acid, tartaric acid, and sodium bicarbonate through an 80-mesh sieve respectively, and crush sucrose and pass through an 80-mesh sieve for later use.

[0062] The preparation of polyethylene glycol solution in ethanol is the same as in Example 1.

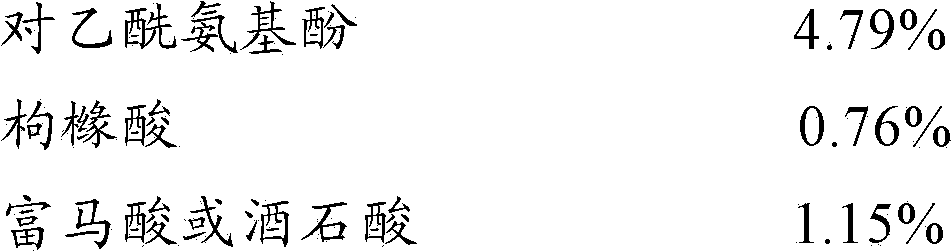

[0063] Weigh the raw materials of the following prescription quantities:

[0064]

[0065] 1) Mix 100g of paracetamol, 20g of citric acid, 30g of tartaric acid, 85g of sodium bicarbonate, 1785g of sucrose, and 15g of stevioside, add 80g of polyethylene glycol ethanol solution to make soft material, and sieve to make wet granules , Put the wet granules evenly into an oven at 55°C, dry for 1 hour, and granulate to obtain dry granules for later use.

[0066] 2) Put the dry granules of step 1) in a mixer, mix for ten minutes, detect the intermediate, and pack it separately.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com