New type coated drug bottle plug and manufacturing method thereof

A manufacturing method and medicine bottle technology, applied in the field of medicine bottle stoppers, can solve problems such as hidden dangers of medicine safety and reliability, influence on use reliability, low production efficiency, etc., achieve excellent medicine compatibility, improve product yield, and solve flexibility small deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

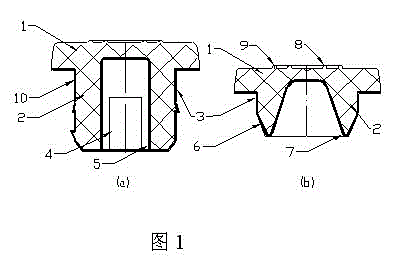

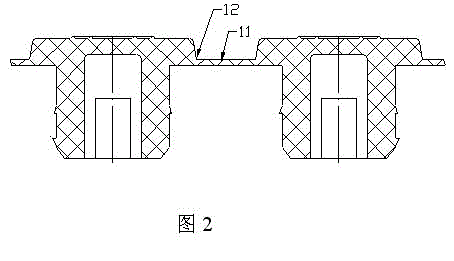

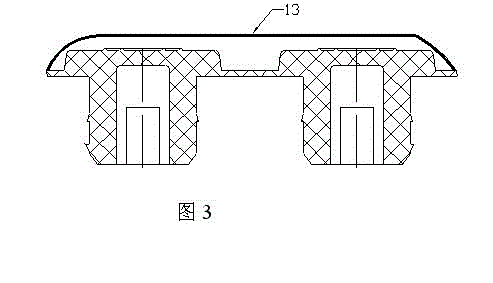

[0041] The present invention as figure 1 , figure 2 , image 3 , Figure 5 As shown, the novel coating drug bottle stopper includes a cork crown and a cork neck. The cork neck has two structural forms, one of which has a cylindrical outer wall with more than one opening on the side, and the inner wall is a cylindrical surface. Another type of neck has a cylindrical outer wall, a guide surface at the bottom, and a tapered cylindrical inner wall. An acupuncture ring is arranged in the center of the upper surface of the plug crown, and a needle punching ring is arranged between the peripheral edge of the acupuncture ring and the peripheral edge of the plug crown. Anti-stick bumps. A coating layer is arranged on the sealing surface of the cork crown, the bottle mouth and the stopper neck.

[0042] The material of the coating layer is parylene, and the thickness of the coating layer is 2.5 μm.

[0043] The material used for the bottle stopper is halogenated butyl rubber.

[...

Embodiment 2

[0052] The present invention as figure 1 , figure 2 , Figure 4 , Figure 5 As shown, the structure and manufacturing method of the novel coating drug bottle stopper are basically the same as in Example 1, the difference is: firstly, the corona parts of the two integrated films are fixed against each other, and then the plastic tape is used to seal the cork crown surface. Positioning, covering and sealing are performed on the peripheral parts of the integrated film that are aligned with each other, and then the entire film is coated on the covered and sealed integrated film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com