Low sugar honey pomelo fruit paste and preparation method thereof

A production method and technology of honey pomelo, which are applied in food preparation, application, food science and other directions, can solve the problems of honey pomelo color, loss of natural flavor and nutrients, short debittering and boiling time, affecting production efficiency, etc. Good taste and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

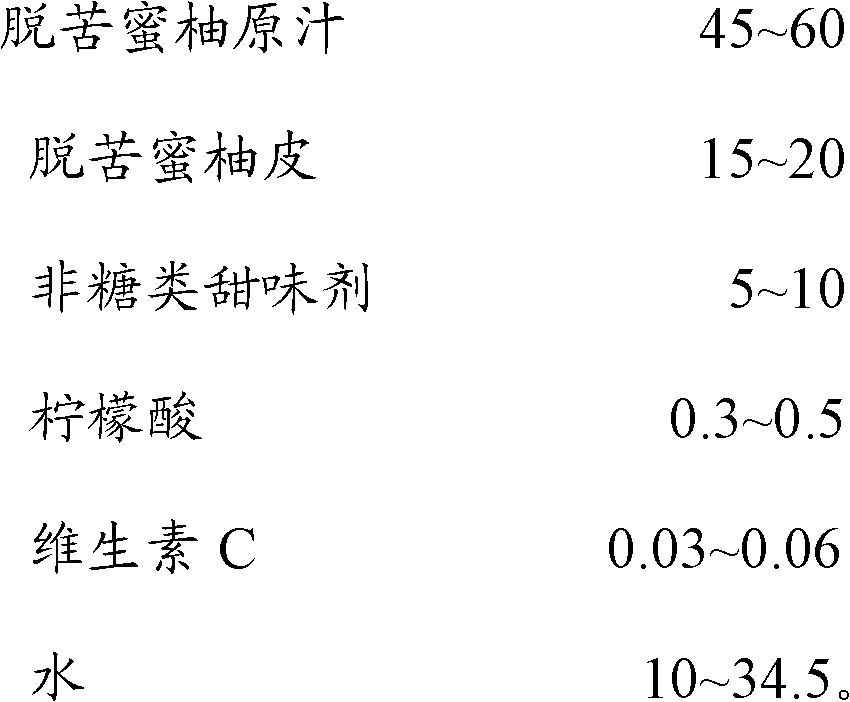

Image

Examples

Embodiment 1

[0034] (1) Clean the raw material honey pomelo with 100ppm of chlorine dioxide, wash the soil, remove pests, scars, damage, rot and other unqualified peels to obtain peel and pulp;

[0035] (2) After the peel is cut into small pieces of 2cm×2cm, warm water at 50°C and honey pomelo peel after cutting are fully mixed according to the mass ratio of 5:3, and then add 0.35% of the peel-water mixture. The above-mentioned debittering solution and 4.5-5.5% sodium chloride are debittered for 60 minutes at a vacuum degree of 0.08 MPa and a temperature of 65° C. During the debittering period, open the cover and turn it up and down every 20 to 30 minutes, and make sure that the cut honey pomelo peels are soaked in the debittering liquid. After debittering, it is rinsed and dried to obtain debittering honey pomelo peel.

[0036] (3) Crushing the pulp and filtering it with a 100-mesh filter, and taking the filtrate to obtain the pomelo juice;

[0037] (4) Evenly mix the pomelo juice and t...

Embodiment 2

[0046] Its processing steps (1), (3), (7), (8), (9) and (10) are identical with embodiment 1.

[0047] The processing conditions of all the other steps are as follows:

[0048] (2) After the peel is cut into small pieces of 2cm×2cm, warm water at 55°C and honey pomelo peel after cutting are fully mixed according to the mass ratio of 5:3, and then add 0.4% of the peel-water mixture. The above-mentioned debittering solution and 5.5% sodium chloride were debittered for 60 minutes at a vacuum of 0.10 MPa and a temperature of 80° C. During the debittering period, open the cover and turn it up and down every 20 to 30 minutes, and make sure that the cut honey pomelo peels are soaked in the debittering liquid. After debittering, it is rinsed and dried to obtain debittering honey pomelo peel.

[0049] (4) Evenly mix the pomelo juice and the ion exchange resin used for beverages in a mass ratio of 6:1, and let it stand for 4 minutes, then centrifuge the pomelo juice and the ion exchan...

Embodiment 3

[0054] Its processing steps (1), (3), (7), (8), (9) and (10) are identical with embodiment 1.

[0055] The processing conditions of all the other steps are as follows:

[0056] (2) After the peel is cut into small pieces of 2cm×2cm, warm water at 45°C and honey pomelo peel after cutting are fully mixed according to the mass ratio of 5:3, and then add 0.3% of the peel-water mixture. The above-mentioned debittering solution and 4.5% sodium chloride were debittered for 90 minutes at a vacuum of 0.10 MPa and a temperature of 60° C. During the debittering period, open the cover and turn it up and down every 20 to 30 minutes, and make sure that the cut honey pomelo peels are soaked in the debittering liquid. After debittering, it is rinsed and dried to obtain debittering honey pomelo peel.

[0057] (4) Evenly mix the pomelo juice and the ion exchange resin used for beverages in a mass ratio of 8:1, and let it stand for 9 minutes, then centrifuge the pomelo juice and the ion exchange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com