Preparation method of cellulose nanofiber-based flexible transparent conductive membrane

A transparent conductive film and nanofiber technology, which is applied in the direction of cable/conductor manufacturing, conductive layer on insulating carrier, circuit, etc., can solve the problems of poor matching of thermal expansion coefficient, etc., and achieve small thermal expansion coefficient, high light transmittance, and flexibility Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

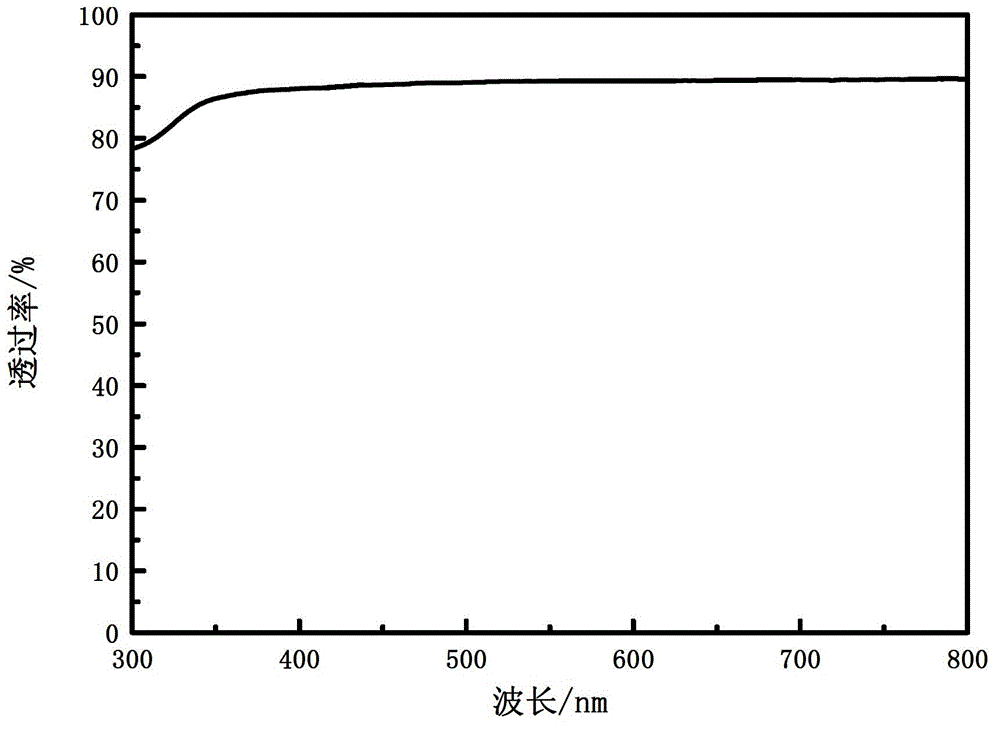

Embodiment 1

[0033] A preparation method of a cellulose nanofiber-based flexible transparent conductive film, the specific steps are as follows:

[0034] Step 1: Ultrasonic defoaming of the CNFs solution for 5 min to obtain a CNFs casting solution with a mass fraction of 0.10%;

[0035] Step 2: Pour the film casting liquid obtained in Step 1 into a flat-bottomed container, seal it and put it into an oven at 30°C, and obtain a CNFs film after the solvent is completely evaporated;

[0036] Step 3: Immerse the CNFs film obtained in Step 2 into AgNO with a temperature of 10 °C, a concentration of 0.1013 mol / L, and a pH of 7.00. 3 After taking out the solution, the film was washed with deionized water and air-dried to obtain CNFs / Ag + membrane;

[0037] Step 4. Adjust the pH value of the GO solution with a concentration of 1 mg / mL to the same as the above AgNO. 3 The pH value of the solution is the same, that is, the pH value is 7.00; then the CNFs / Ag obtained in step 3 + The membrane was i...

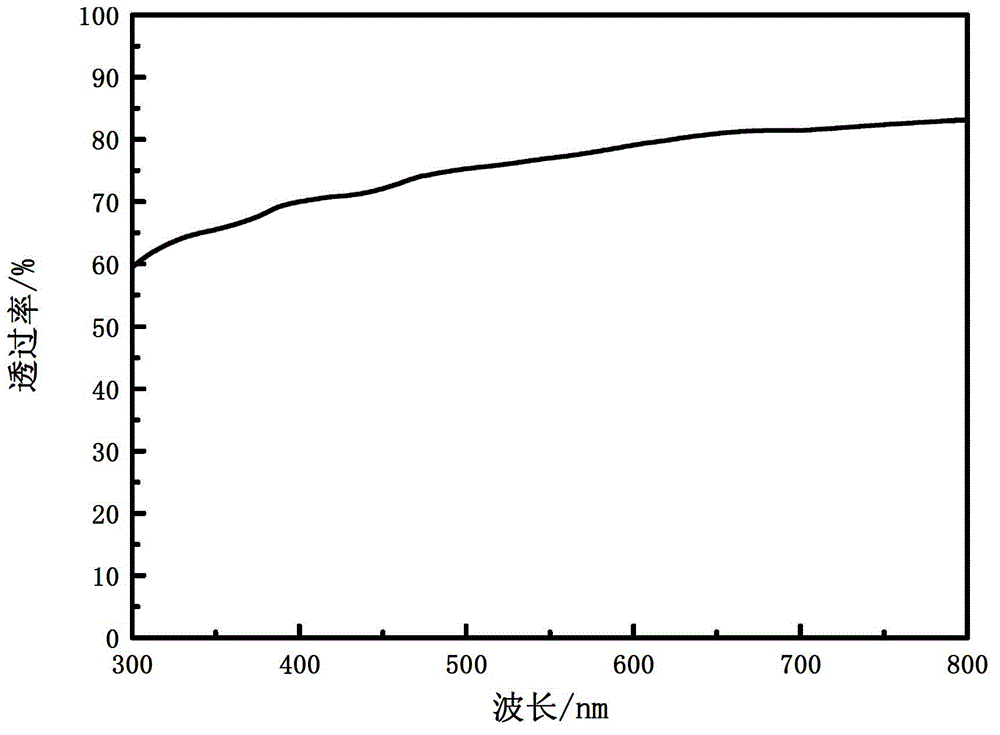

Embodiment 2

[0042] A preparation method of a cellulose nanofiber-based flexible transparent conductive film, the specific steps are as follows:

[0043] Step 1: Ultrasonic defoaming of the CNFs solution for 30 min to obtain a casting solution with a mass fraction of CNFs of 0.23%;

[0044]Step 2: Pour the film-casting liquid obtained in step 1 into a polypropylene watch glass, control the liquid level of the film-casting liquid in the watch glass to be 1.3 cm, seal it for a period of time, and put it into an oven at 40°C. After the solvent is completely evaporated, a CNFs film is obtained;

[0045] Step 3: Immerse the CNFs membrane obtained in Step 2 into CuCl at a temperature of 30 °C and a concentration of 0.0157 mol / L (pH value of 4.66). 2 After taking out the solution, rinse the film with deionized water and dry it with air;

[0046] Step 4. Adjust the pH value of the GO solution with a concentration of 8.7 mg / mL to the same as the above CuCl. 2 The pH value of the solution (4.66) ...

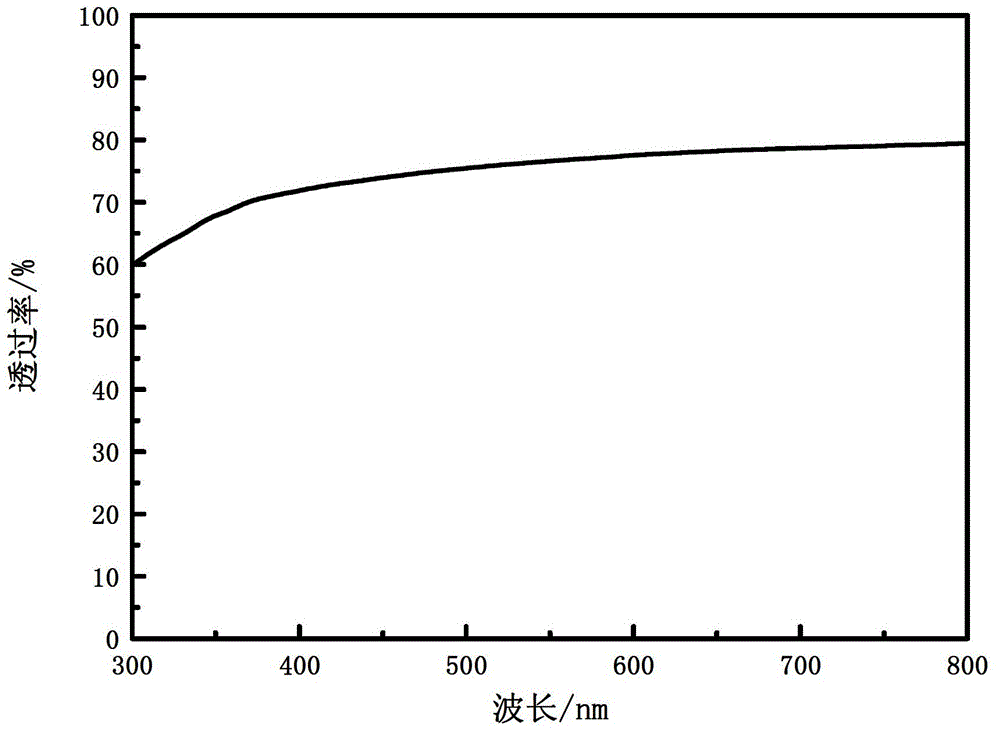

Embodiment 3

[0051] A preparation method of a cellulose nanofiber-based flexible transparent conductive film, the specific steps are as follows:

[0052] Step 1. Ultrasonic defoaming of the CNFs solution for 1 h to obtain a casting solution with a mass fraction of CNFs of 0.27%;

[0053] Step 2, pour the film casting liquid obtained in step 1 into a flat-bottomed container, evaporate naturally, and obtain a CNFs film after the solvent is completely evaporated;

[0054] Step 3: Immerse the CNFs membrane obtained in Step 2 into AlCl at a temperature of 70 °C and a concentration of 0.0371 mol / L (pH value of 4.02). 3 After taking out the solution, rinse the film with deionized water and dry it with air;

[0055] Step 4. Adjust the pH of the GO solution with a concentration of 3.5 mg / mL to the same value as the above AlCl. 3 The pH value of the solution (4.02) was the same, and then the CNFs / Al obtained in step 3 3+ The membrane was immersed in GO solution at a temperature of 70 °C, and afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com