A kind of manufacturing method of graphene organic electroluminescent device

A production method and a luminescence technology, which are applied in organic light-emitting devices, organic light-emitting device manufacturing/processing, organic semiconductor devices, etc., can solve problems such as current hysteresis, achieve suppression of current hysteresis, have obvious effects, and improve device electro-optical conversion efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

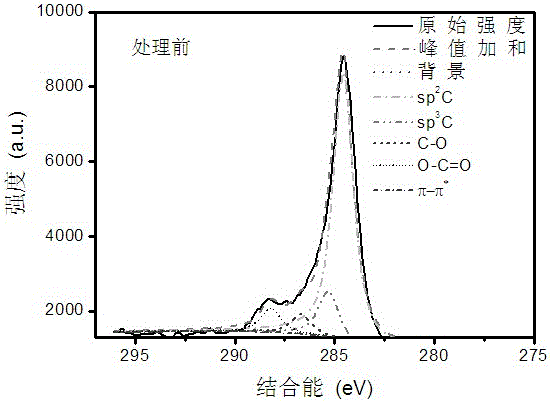

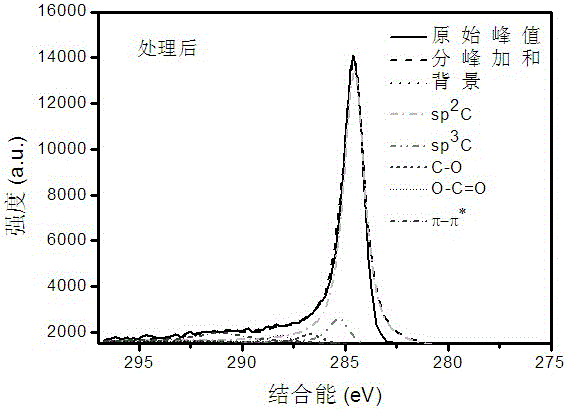

Image

Examples

Embodiment 1

[0031] A. Glass substrate 1, use acetone and ethanol cotton balls to scrub, then use acetone, ethanol and deionized water to sonicate for 10 minutes, then dry at 100 degrees;

[0032] B. Transfer the three to five layers of graphene film 2 prepared by vapor deposition to the glass substrate 1 by wet transfer, and dry at 160 degrees. After 30 minutes, use acetone to soak the film to clean the PMMA, ten minutes each time. repeat three times;

[0033] C. Polyethylenedioxythiophene: polystyrene sulfonic acid (PEDOT: PSS), which is the hole transport layer 3, is attached to the glass substrate 1 by spin coating, and the spin coating speed of the first layer is 2000rpm for 1 minute , followed by annealing at 120 degrees for half an hour, the spin coating speed of the second layer is 1000rpm, 1 minute, and then annealing at 120 degrees for half an hour;

[0034] D. Using 2,6-bis((9H-carbazol-9-yl)-3,1-phenylene)pyridine (26DCzPPy): 1,1-bis[4-[N,N-bis(p-toluene )amino]phenyl]cyclohe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com