Insulation monitoring and life prediction method of cross linked polyethylene cable

A cross-linked polyethylene and cable insulation technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve problems such as failure to reflect the process of insulation deterioration and large-scale dead zones in the middle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

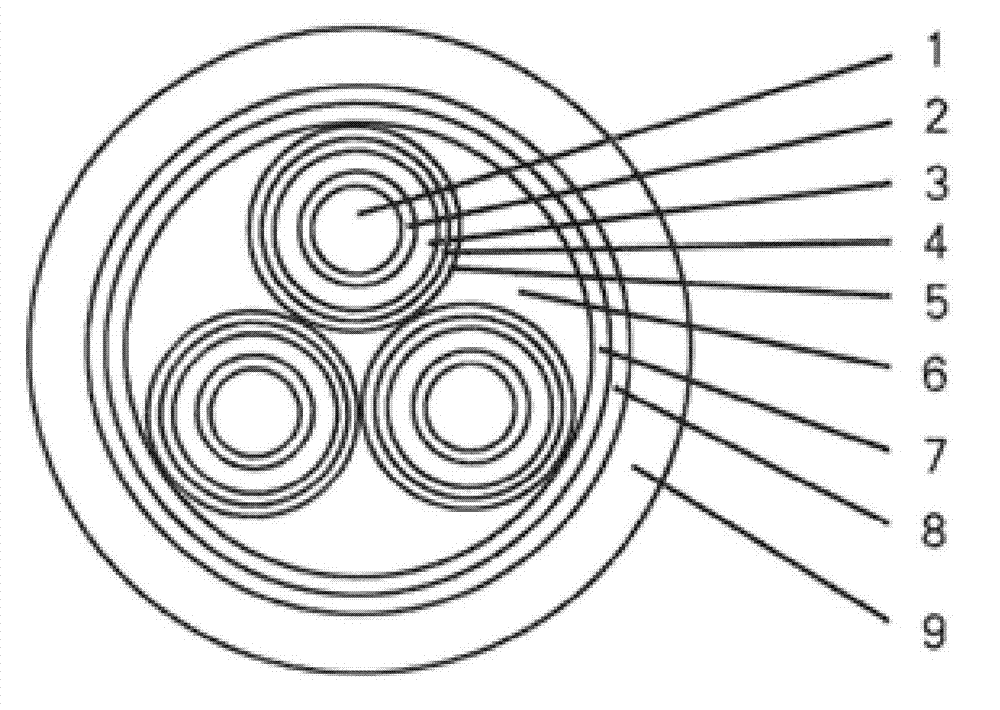

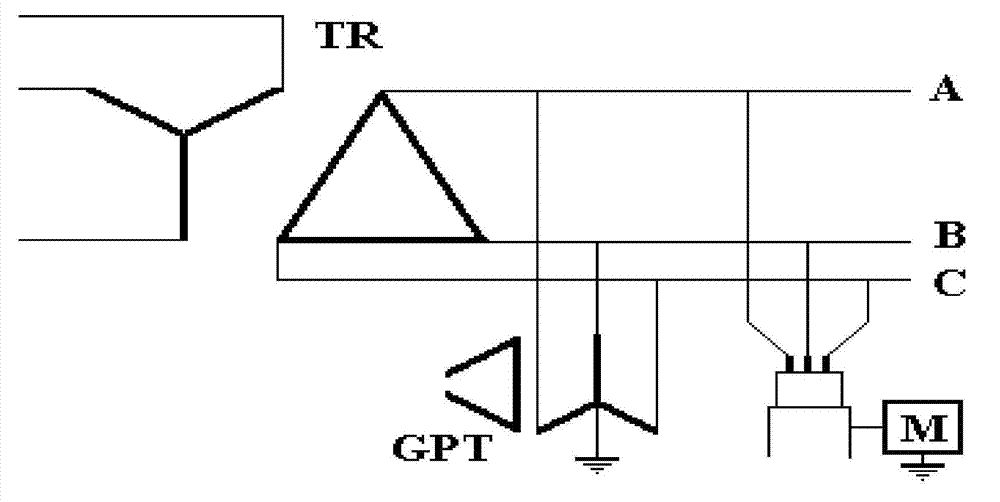

[0032] see figure 1 , XLPE cable insulation monitoring and life prediction method, one of the leakage current, insulation resistance and dielectric loss angle of XLPE cable is used as the detected quantity α; the prediction method includes the following steps:

[0033] a. Calculate the detected quantity α and the mutation rate β of the detected quantity α in real time, and give a real-time alarm for the real-time mutation rate β greater than 0.01, wherein the mutation rate β=(α n -α n-1 ) / α n-1 , αn, αn-1 are the sampling values of the detected quantity α at different times;

[0034] b. Regularly calculate the daily average value of the detected quantity α monthly average annual average the size of which α ‾ d = Σ 0 24 ( α / 24 ) , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com