Liquid leakage detection line

A technology for detecting line and liquid leakage, applied in the direction of detecting the appearance of fluid at the leakage point, using liquid/vacuum degree for liquid tightness measurement, etc., can solve liquid leakage, building ground corrosion, various equipment misoperations, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

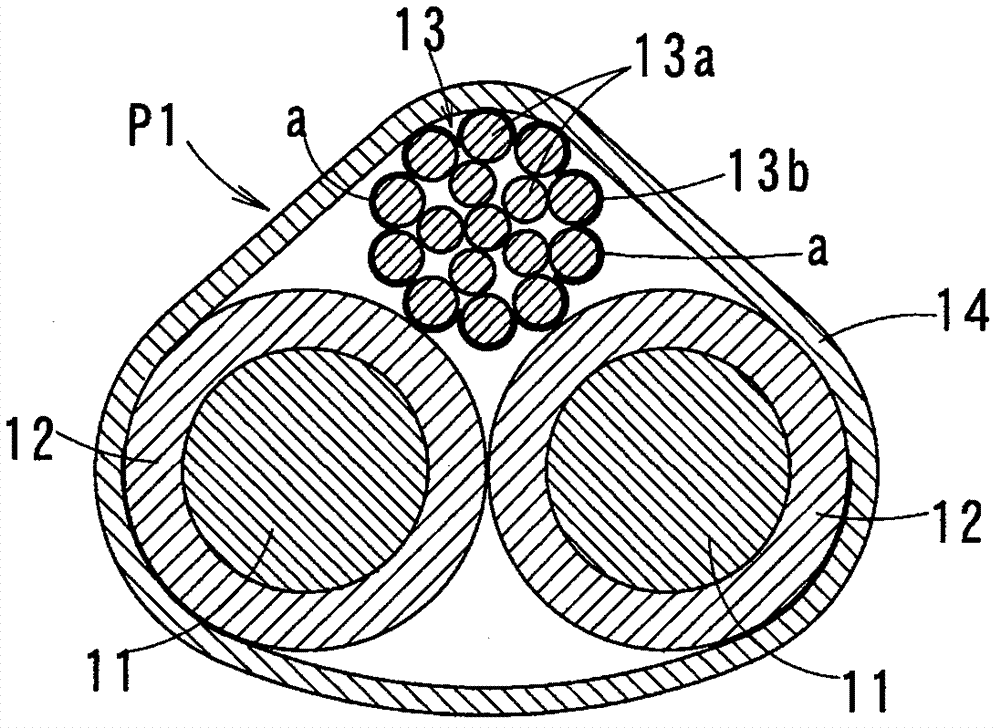

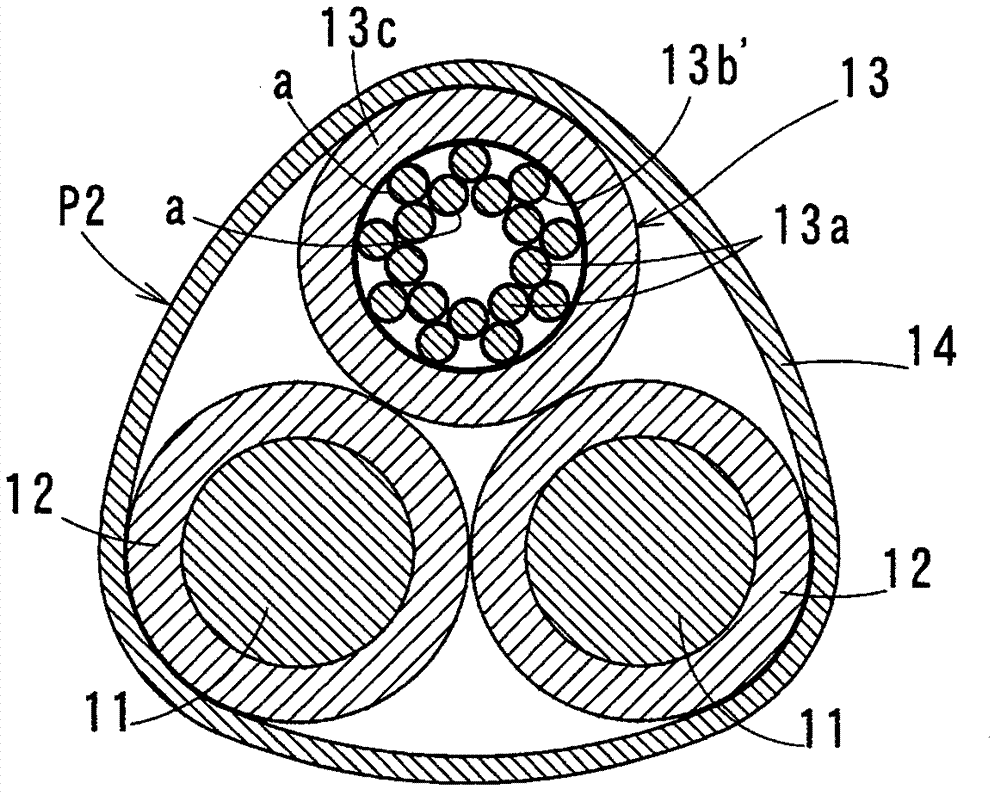

[0038] figure 1 , figure 2 Representing the first and second embodiments of the present invention, as shown in the following table 1, the leakage detection lines P1 and P2 of the first and second embodiments are knitted fabrics each made of white polyethylene yarns of single fibers with an outer diameter of 0.3 mm 12 Covered with tinned soft copper twisted wire (wire diameter: 0.18mm×13 pieces = 0.33m 2 ) To form a pair of conductors 11, 11, twist the covering conductors 11, 11 and the linear color body 13, and cover the outer circumference with an outer braid 14 of composite fiber white polyethylene wire with an outer diameter of 0.1 mm (Maximum outer diameter: 3.6mm).

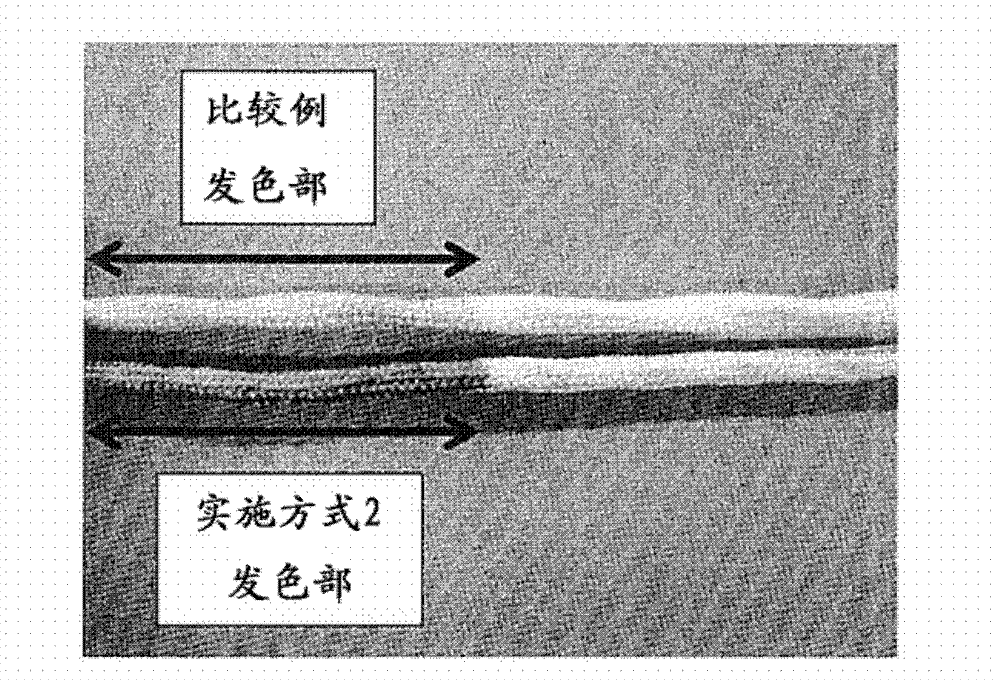

[0039] At this time, the color body 13 is a twisted yarn 13b (diameter: 1 mm, embodiment 1) of a composite fiber white polyester yarn 13a with an outer diameter of 0.1 mm, and a cylindrical braid 13b' (diameter: 1 mm, embodiment 2) To color the red colorant a, in Example 2, the outer peripheral surface was fur...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap