Material charging and vibratory material feeding device with adjustable inclination angles

The technology of a feeding device and a driving device is applied in the field of metallurgy, which can solve the problems of adding links and equipment in the production of electric furnace logistics system, and the end openings of scrap steel and other materials slipping off, increasing the operations of pin loading and pulling pins, etc., so as to achieve improved safety performance, Save operation time and reduce the effect of auxiliary operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

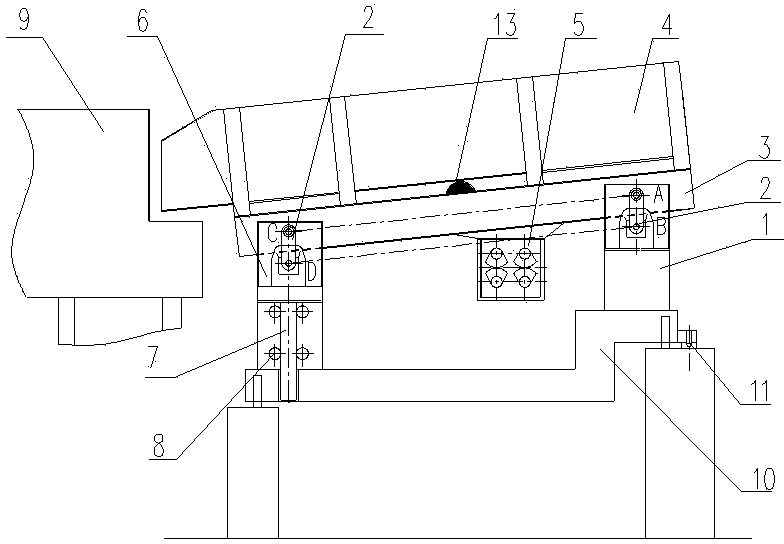

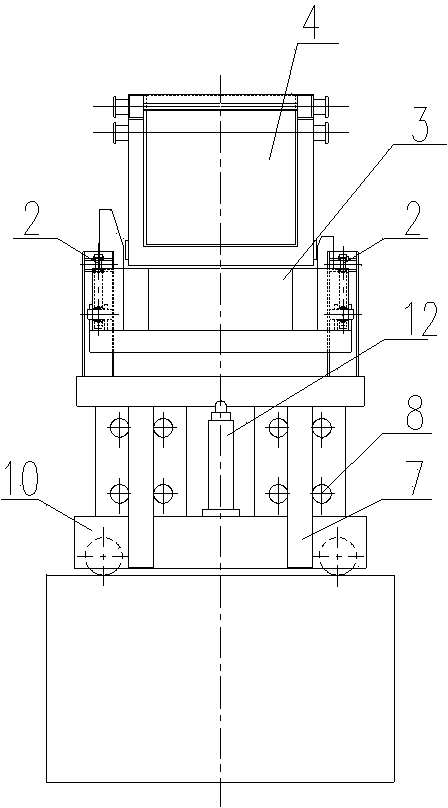

[0026] Such as figure 1 as shown, figure 1 It is a schematic structural diagram of an embodiment of the tilt-adjustable charging and vibrating feeding device of the present invention, specifically showing that the long hopper is in the tilting feeding position.

[0027] The charging and vibrating feeding device with adjustable inclination of the present embodiment comprises a vibrating table 3, a long material trough 4 installed on the vibrating table 3 and an inclination adjusting device for adjusting the inclination angle of the long material trough 4, and the inclination adjusting device includes a vibrating Table 3 is hingedly connected with a length-adjustable elevating frame 6 and a driving device corresponding to elevating frame 6 and used to drive elongating and shortening elevating frame 6 . The driving device can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com