Automatic judgement method for pipe explosion and water leakage of solar water heating system

A solar water heating and automatic judgment technology, applied in the field of solar thermal utilization, can solve the problems of misjudging the explosion of the pipe and the failure of the electrodes to form a current loop.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

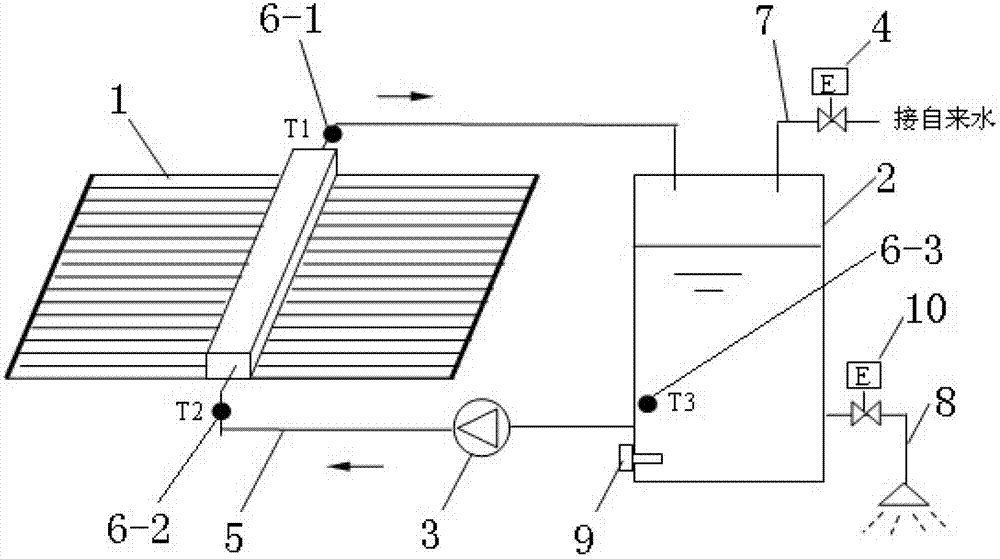

[0042] A solar water heating system using temperature difference circulation.

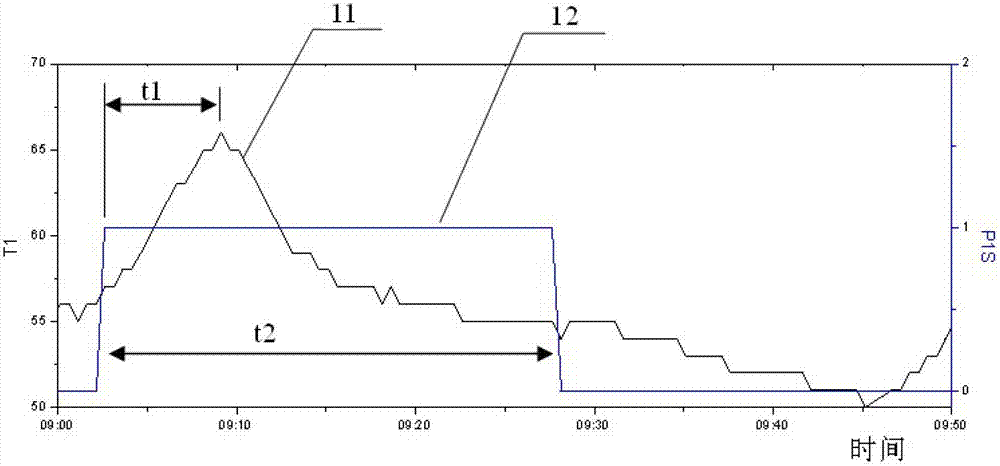

[0043] During normal operation as image 3 As shown, at 9:02:38, the water pump starts to start the temperature difference cycle, and the temperature at the collector outlet starts to rise from 57°C. At 9:09:08, the temperature reaches the highest point of 66°C, and then the collector outlet temperature begins to drop. , until 9:28:08, the water pump stops running, and the temperature at the outlet of the collector is 54°C. It can be calculated that the time t1 at which the temperature peak appears is 7.5 minutes.

[0044] like Figure 4 As shown, the solar hot water system has water leakage from the fried pipe. Since the water leakage is not very large, the water temperature can still rise after the water pump is started. The time when the water pump starts is 14:44:55, and the time when the temperature reaches the highest It is 15:00:54, and the time t1 to reach the highest peak is 16 minutes,...

specific Embodiment 2

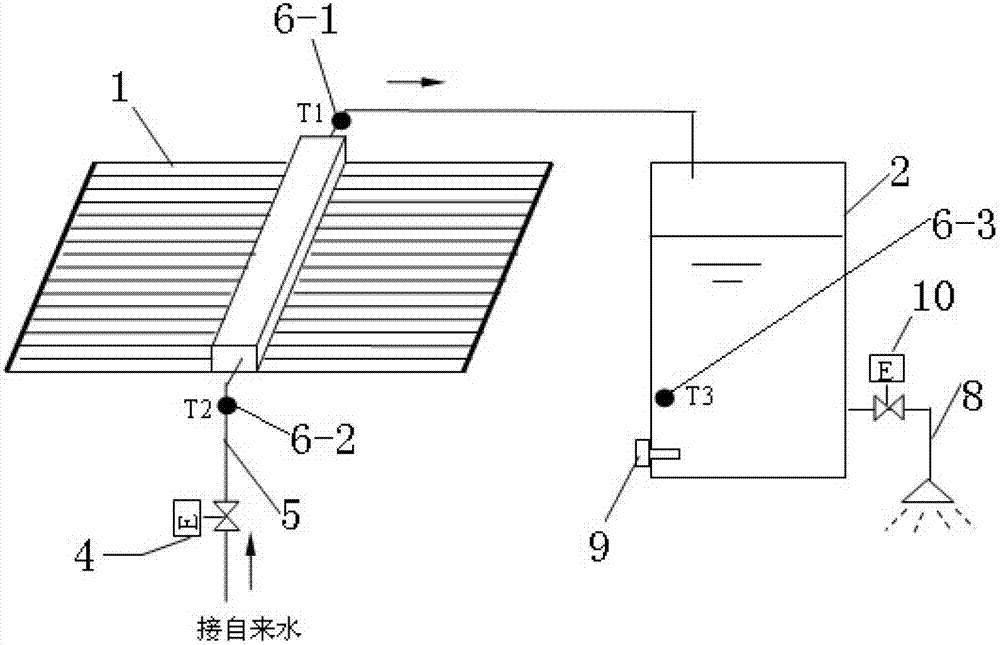

[0045] A solar hot water system adopts the constant temperature water outlet method. When the solenoid valve is opened, the time t1 for the peak temperature of the collector outlet is 3 minutes, and the water level of the water tank rises at a speed of 70-76mm / min. When there is water leakage from the fried tube, the peak time t1 of the outlet temperature of the collector reaches 10 minutes, and the water level of the water tank rises at only 22mm / min.

specific Embodiment 3

[0046] For solar hot water systems with multiple collector arrays and multiple circulation loops, the constant temperature water outlet operation mode is often used when the water tank is not full. When the water tank is full, it is changed to the temperature difference circulation mode. When the water consumption is less than 50%, Then change to the constant temperature outlet water operation mode. It is necessary to record and compare the normal values according to the outlet temperature of each collector array and the status of the water pump and solenoid valve, and then judge which collector is the current one according to the current operating mode (temperature difference cycle or constant temperature water outlet). There was water leakage from the frying tube in the heater display.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com