Method for manufacturing backlight module and double-sided adhesive for fixing same

A manufacturing method and backlight module technology, applied in the direction of light source fixation, fixed lighting device, optics, etc., can solve the problems of inconvenience, time-consuming operation, material waste, etc., and achieve the effects of saving man-hours and costs, convenient operation, and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Reference herein to "one embodiment" or "an embodiment" refers to a particular feature, structure or characteristic that can be included in at least one implementation of the present invention. "In one embodiment" appearing in different places in this specification does not all refer to the same embodiment, nor is it a separate or selective embodiment that is mutually exclusive with other embodiments.

[0024] The manufacturing method of the LED backlight module of the present invention mainly includes the following steps: firstly provide a backboard; then provide an LED lamp board, the structure and manufacturing method of the LED lamp board will be described in detail below; The LED lamp board is pasted on the back board. In order to highlight the inventive content of the present invention, other structures and assembly processes of the backlight module will not be described in detail in the present invention.

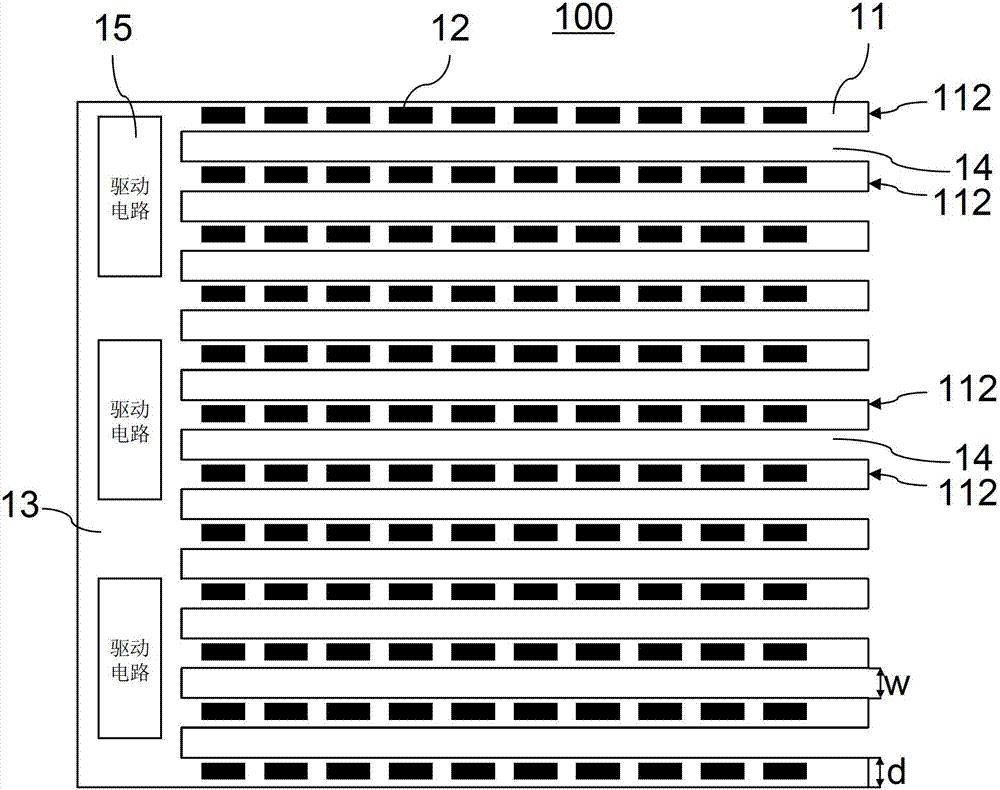

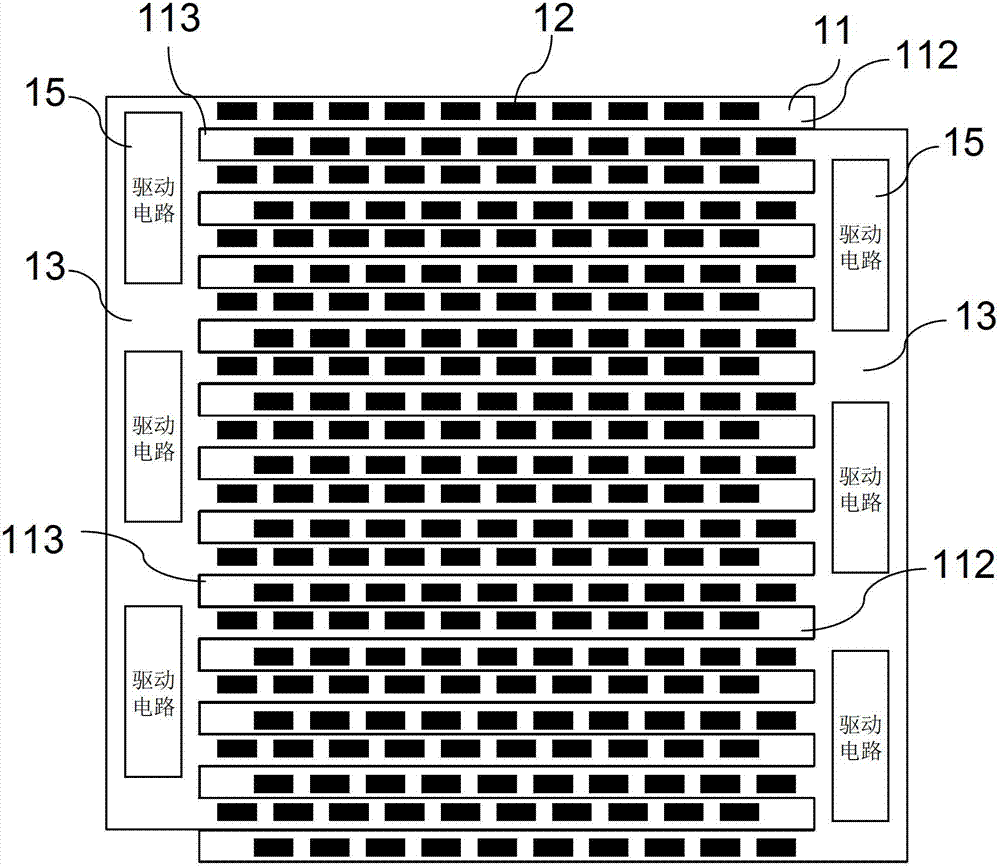

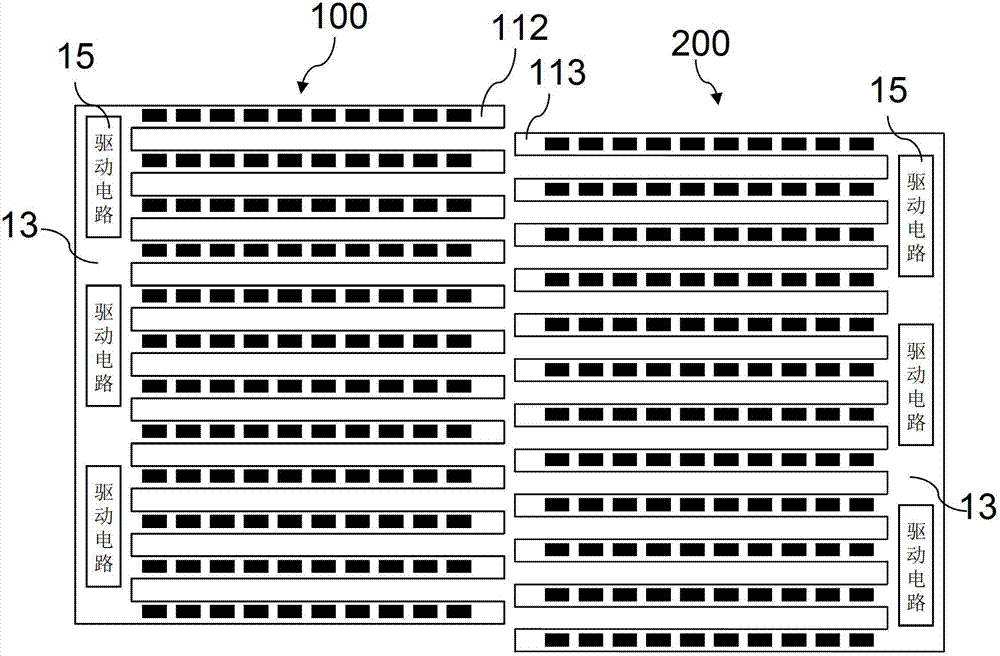

[0025] see figure 1 As shown, it shows a schematic str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com