Frame structure integral air flue for multi-valve diesel engine

A frame structure, diesel engine technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems affecting the economy and emission level of diesel engines, uneven combustion of each cylinder, inconsistent swirl ratio, etc., to improve the quality of castings and The effect of production efficiency, reduced assembly errors, improved economy and emission levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The structural principle of the present invention will be further described below in conjunction with the accompanying drawings and taking a four-cylinder diesel engine as an example, but the content covered by the present invention is not limited to the following embodiments.

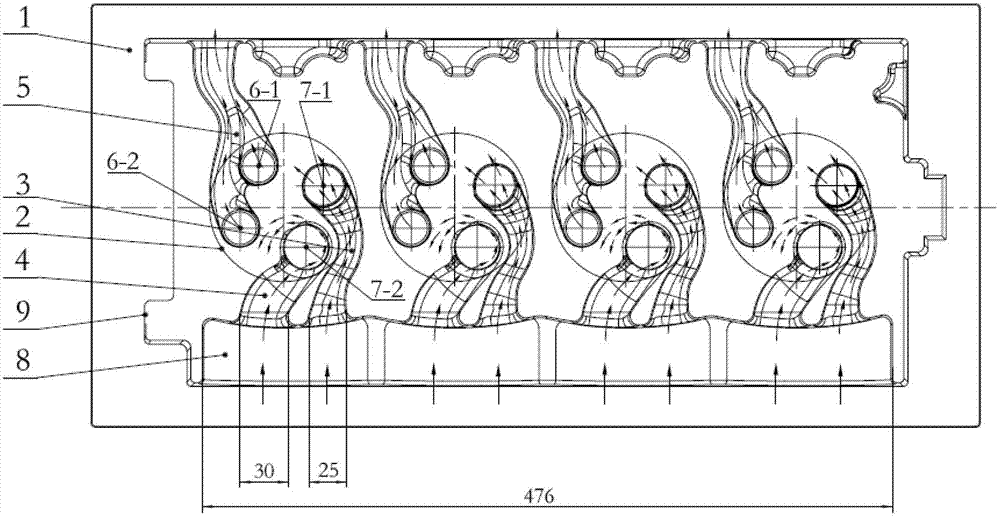

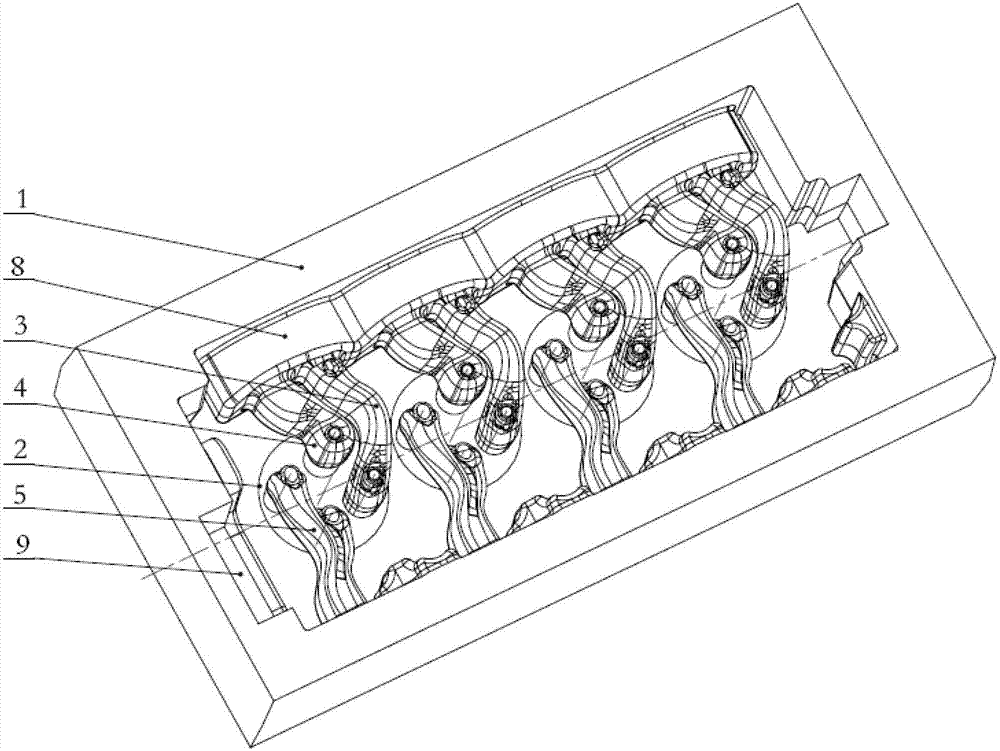

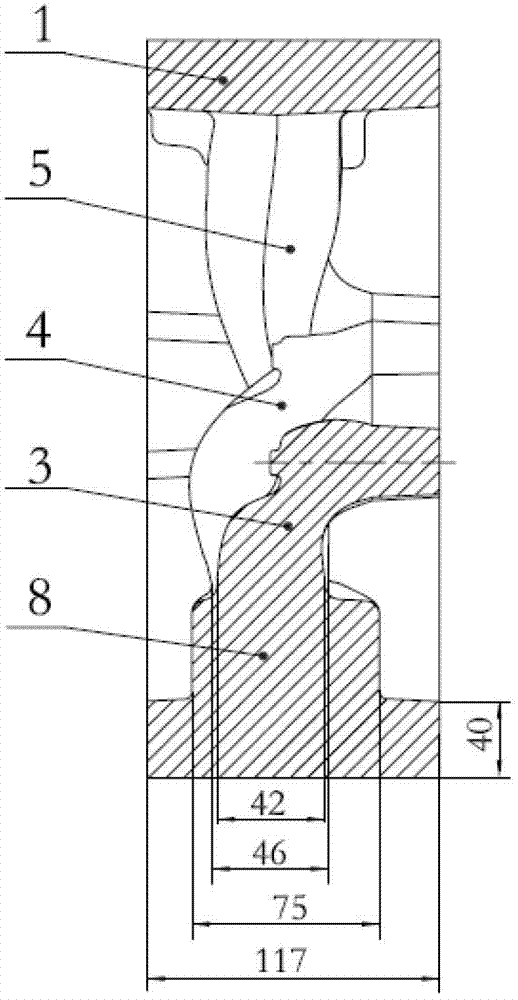

[0011] The frame structure of the four-valve diesel engine is an integral air passage, and its structure is as follows: the outer frame 1 of the air passage is provided with four cylinders 2, and each cylinder is provided with a tangential intake passage 3, a spiral intake passage 4 and a parallel exhaust passage 5. The tangential intake port, the spiral intake port and the parallel exhaust port are evenly distributed around the cylinder, and the two branches of the parallel exhaust port are connected with the first exhaust valve 6-1 and the second exhaust valve 6-1 respectively. 2 are communicated, the tangential inlet port is communicated with the first intake valve 7-1; the spiral inlet port i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com