Production process of circuit board with silicone keys

A production process and circuit board technology, which is applied in the field of forming molds corresponding to the process to achieve the effect of reducing the occurrence of bad conditions, reducing production costs, and saving product production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

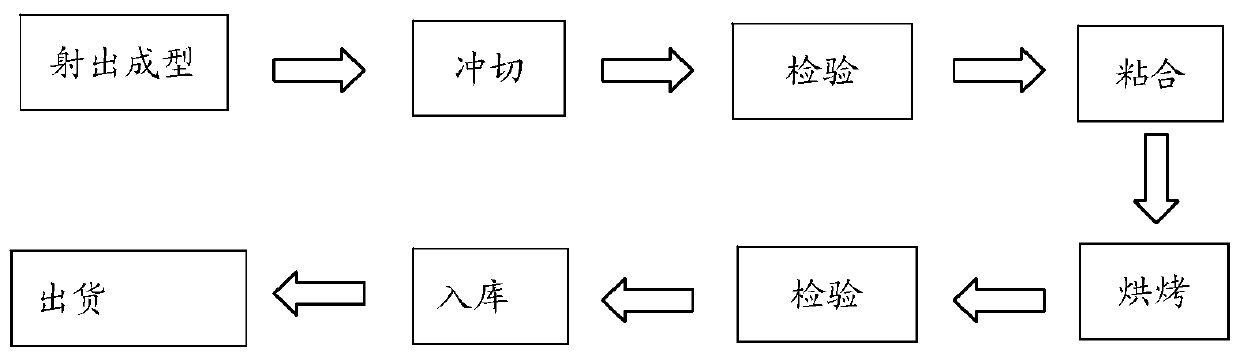

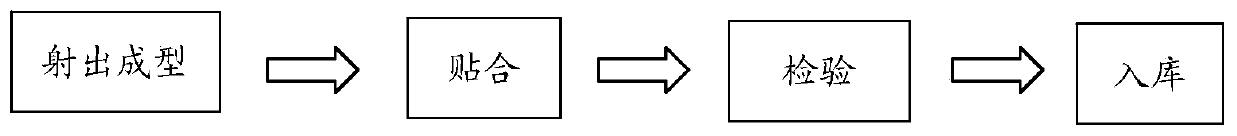

[0024] refer to figure 2 , the production process of the circuit board with silica gel button provided by the invention comprises the following steps:

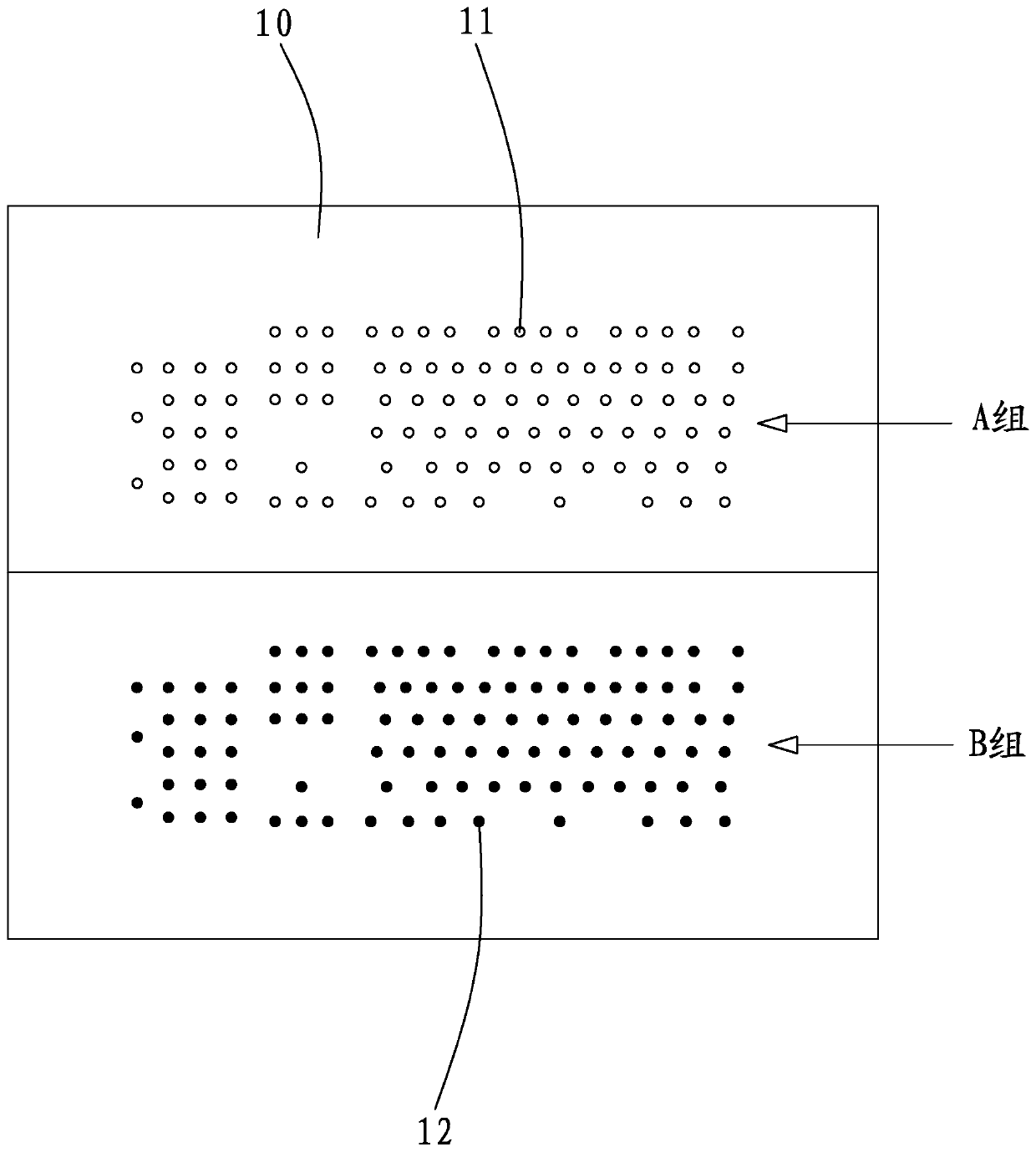

[0025] ①Silicone button injection molding and flexible circuit board gluing: While the silicone button is being injected and molded through the molding mold, the position of the silicone button to be pasted on the flexible circuit board is synchronously positioned and glued on the gluing jig; among them, the molding mold One-to-one correspondence between the injection points and the assembly position of the silicone button on the flexible circuit board to complete the one-to-one correspondence of a single silicone button injection molding;

[0026] ② Lamination and molding of the silicone button and the flexible circuit boar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com