Air duct installation component

A technology for installing components and air ducts, which is applied to household appliances, applications, and display cabinets, etc., can solve the problems of affecting assembly efficiency, single structure, and large gaps in the assembly of the box, saving manpower, improving assembly efficiency, and installing Simple and convenient steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

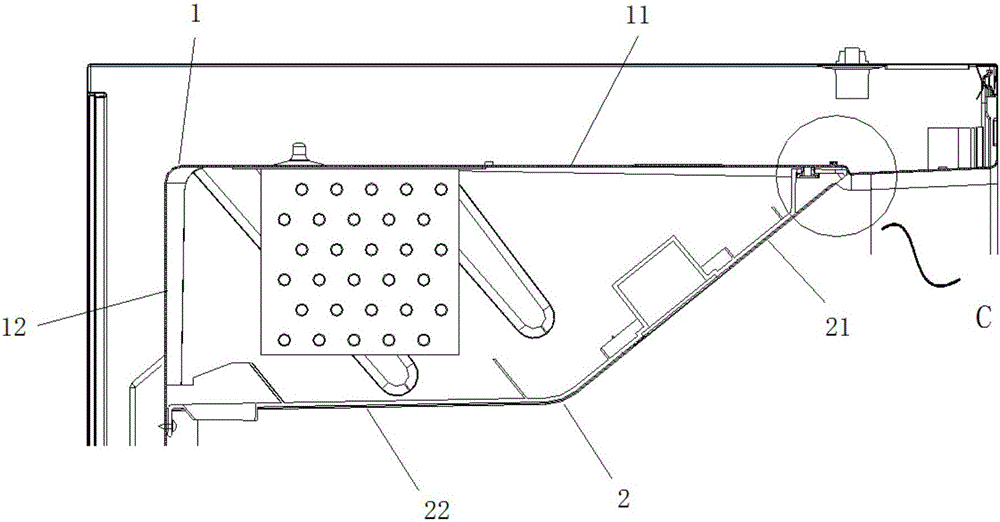

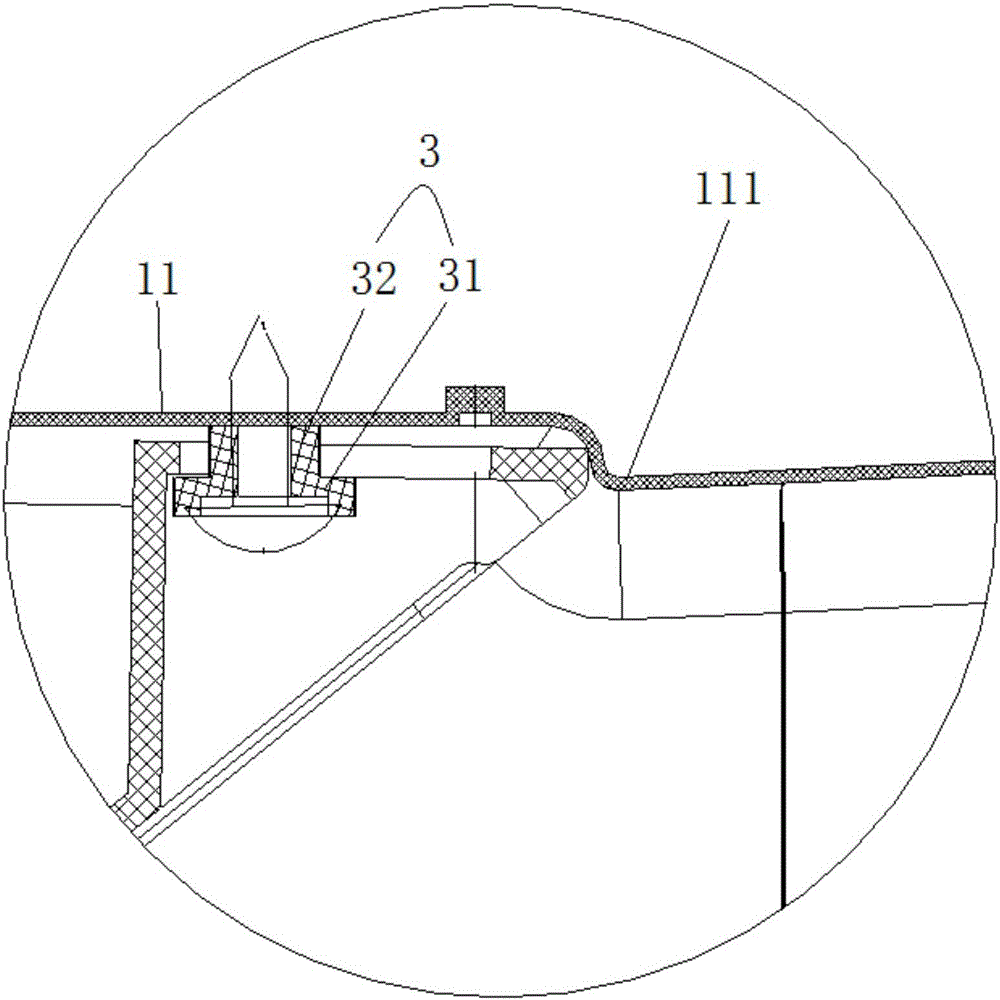

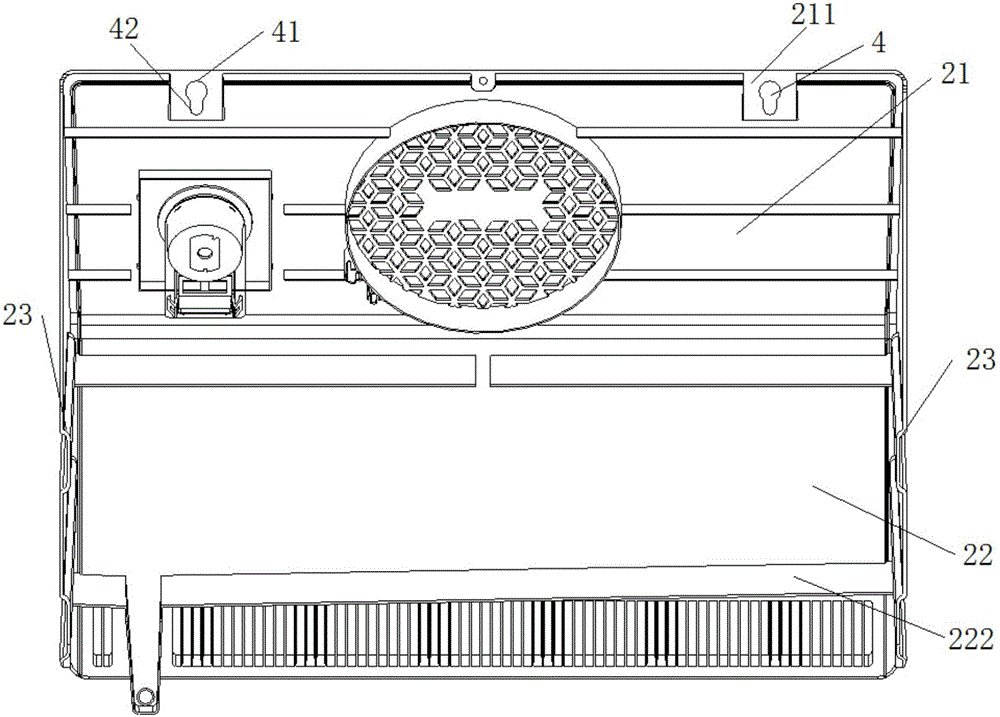

[0055] like Figure 1-9 As shown, an air duct installation assembly is arranged inside the box body, including a box inner liner 1 and an air duct housing 2 connected to the box inner liner 1, the air duct housing 2 is connected with the top surface 11 of the box liner and a side surface 12 of the box liner to form an air duct, the air duct shell 2 includes an integrally formed inclined panel 21, a bottom wall 22 and two side walls 23, the The inclined panel 21 has a common side with the bottom wall 22 and the two side walls 23; the edge of the inclined panel 21 is provided with at least two connecting plates 211 parallel to the bottom wall, and each connecting plate 211 is provided with A connection hole 4 . At least two connecting pieces 3 are provided at the positions where the top surface 11 of the tank liner matches the connecting holes 4 , and the connecting holes 4 correspond to the connecting pieces 3 one by one and are snap-connected. The connecting piece is directl...

Embodiment 2

[0061] like Figure 1-9 As shown, an air duct installation assembly is arranged inside the box body, including a box inner liner 1 and an air duct housing 2 connected to the box inner liner 1, the air duct housing 2 is connected with the top surface 11 of the tank inner tank and a side surface 12 of the tank inner tank to form an air duct, the air duct housing 2 is provided with at least two connection holes 4, the top surface 11 of the tank inner tank is connected to the At least two connecting pieces 3 are provided at matching positions of the connecting holes 4 , and the connecting holes 4 correspond to the connecting pieces 3 one-to-one and are snap-connected. The central axis of the connecting piece is provided with a through hole, and the bolt passes through the through hole and is connected with the top surface of the tank inner tank by threads, or the top surface of the tank inner tank is also provided with a bolt hole correspondingly. The bolts pass through the throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com