Tail gas-driven turbine generating set for internal combustion engine

A technology of turbine power generation and internal combustion engine, which is applied in the direction of circuit devices, exhaust devices, battery circuit devices, etc., and can solve the problems of energy loss and poor use of exhaust gas, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

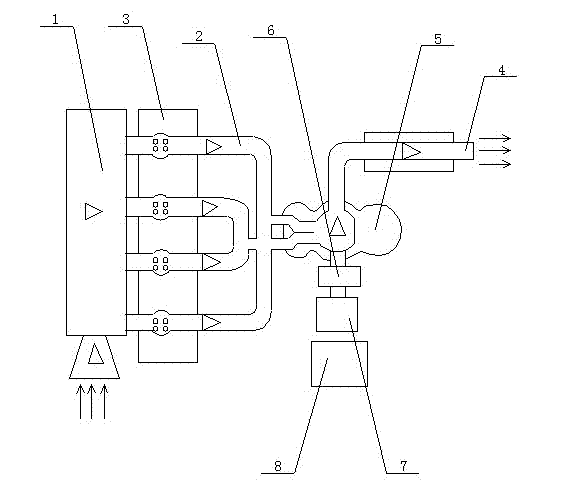

[0011] refer to figure 1 , The specific embodiment adopts the following technical scheme: it includes a turbine 5 and an air passage part 2, a turbine speed regulating mechanism part 6 and an engine part 3.

[0012] Described turbine 5 and gas passage part 2 mainly comprise the cavity that turbine 5, turbine shaft, exhaust gas inlet 1 and exhaust gas outlet 4 form, and the diameter of exhaust gas inlet 1 is less than the diameter of exhaust gas outlet 4, and by high-pressure exhaust gas inlet like this 1 is blown in to drive the turbine 5 to rotate, and then the pressure of the exhaust gas is reduced and the exhaust gas is discharged from the exhaust outlet 4. After this process, the turbine 5 drives the turbine shaft to make a circular motion, so that the turbine shaft drives the turbine 5 speed change mechanism to achieve the purpose of energy conversion.

[0013] The turbine speed regulating mechanism part 6 is converted into the speed range required by the rotor of the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com