Thermoplastic non-metal composite material curtain wall board for architectural decoration and preparation method thereof

A composite material and architectural decoration technology, which is applied in the direction of architecture, building components, building structures, etc., can solve problems such as single waterproof performance and thermal insulation performance, difficult to balance waterproof and thermal insulation, and unfavorable building energy saving, etc., to achieve construction The effect of simplicity, light weight, hardness and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

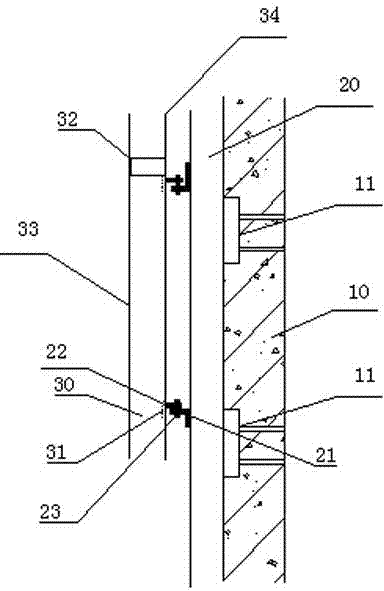

Image

Examples

preparation example Construction

[0036] Adopt the preparation method of thermoplastic non-metallic composite material curtain wall board for building decoration of the present invention to mainly comprise the following steps:

[0037] Step 1, mix and stir the reinforcing agent, polypropylene, flow modifier, titanium dioxide and antioxidant in a mixer according to the formula amount;

[0038] Step 2, adding the above-mentioned mixed raw materials into the hopper of the twin-screw extruder, and heating and forming;

[0039] Step 3, extruding the strip-shaped composite material after heating and molding by the extruder, and cooling the composite material;

[0040] Step 4, putting the cooled strip composite material into a granulator to be processed into granular composite material particles;

[0041] Step 5, putting the composite material particles into an oven for heating and drying;

[0042] Step 6, add the dried composite material particles into the barrel of the injection molding machine, heat and melt, in...

Embodiment 1-12

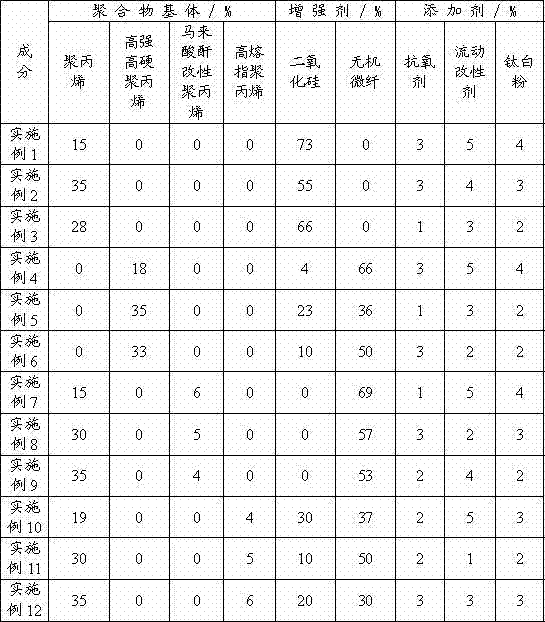

[0048] Table 1: The following is the embodiment 1-12 of each different formulation

[0049]

[0050]Fully mix and stir the above-mentioned raw materials in the mixer according to the formula amount in Table 1, and quantitatively add the mixed raw materials into the hopper of the twin-screw extruder through the feeding port and the bypass feeding port, and heat and form; then pass through the extruder Extrude the strip-shaped composite material after heating and molding from the die mouth, and place the strip-shaped composite material in a water tank to cool down to room temperature; put the strip-shaped composite material after cooling into a granulator and process it into granular composite Material particles; put the composite material particles into an oven at 100°C to 120°C for heating and drying to remove moisture; add the dried composite material particles into the barrel of the injection molding machine, heat to melt the composite material particles, Enter the comput...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com