Liquid phase hydrogenation method

A liquid-phase hydrogenation and hydrogenation reactor technology, which is applied in the field of hydrocarbon oil hydrogenation, can solve the problems of large investment and energy consumption, and achieve the effects of less equipment investment, less catalyst consumption, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

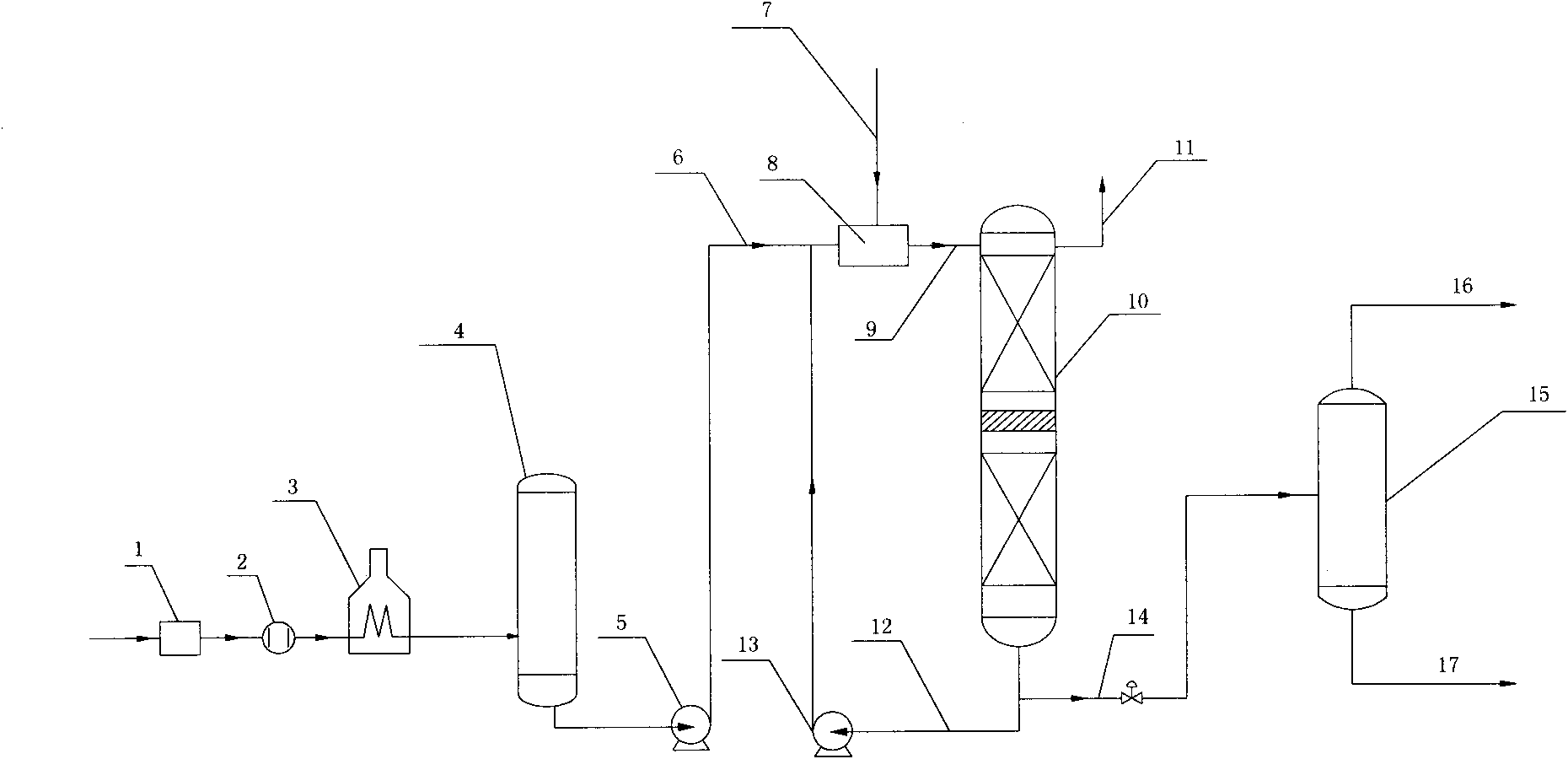

[0040] like figure 1As shown, the reactor shown in the figure is a two-stage catalyst bed. The feedstock oil (straight-run diesel oil) passes through the feedstock oil filter 1 to remove particles in the feedstock oil, then heats up to 330°C through the heat exchanger 2, and then enters the reaction feed heating furnace 3 to be heated to 380°C, and then enters the feedstock oil buffer tank 4. Send it to the mixing dissolver 8 through the hydrogenation feed pump 5, so that the fresh raw material oil 6, the cycle oil 12 and the hydrogen gas 7 are mixed in the mixing dissolver 8 to form a mixture flow 9, which enters the reactor 10, and is hydrogenated After the gas 11 is separated from the top of the reactor, the liquid is contacted with the catalyst to react, the gas is discharged from the top of the reactor, part of the reaction effluent is used as circulating oil 12, and the other part 14 enters the low-pressure separator 15 after being depressurized by the pressure reducing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com