Rapid permeation bottom underfill and preparation method thereof

An underfill and fast technology, which is used in chemical instruments and methods, adhesives, epoxy resins, etc., can solve the problems of uneven rounding around the chip, slow filling speed, and more residual glue, etc., to achieve a wide range of products. , Improve work efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

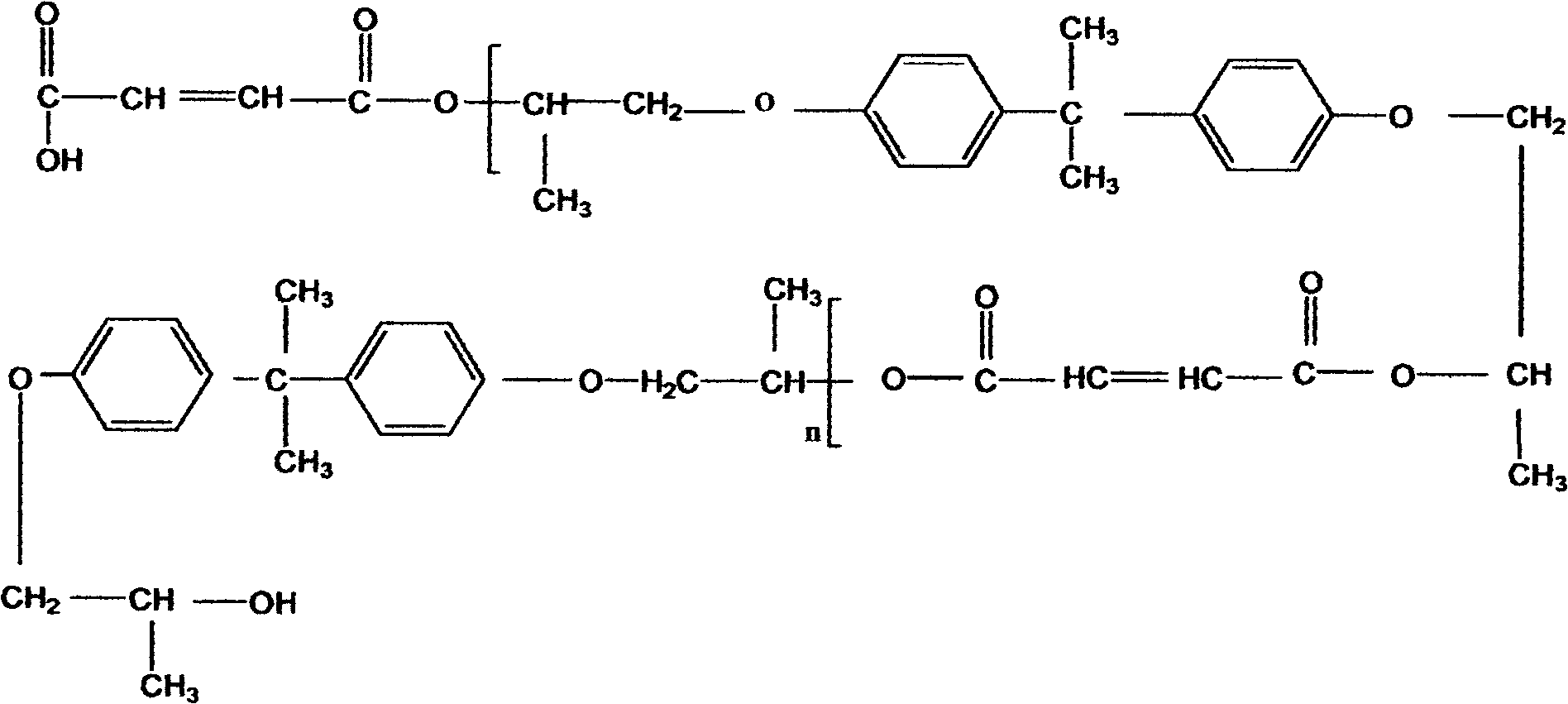

Method used

Image

Examples

Embodiment 1

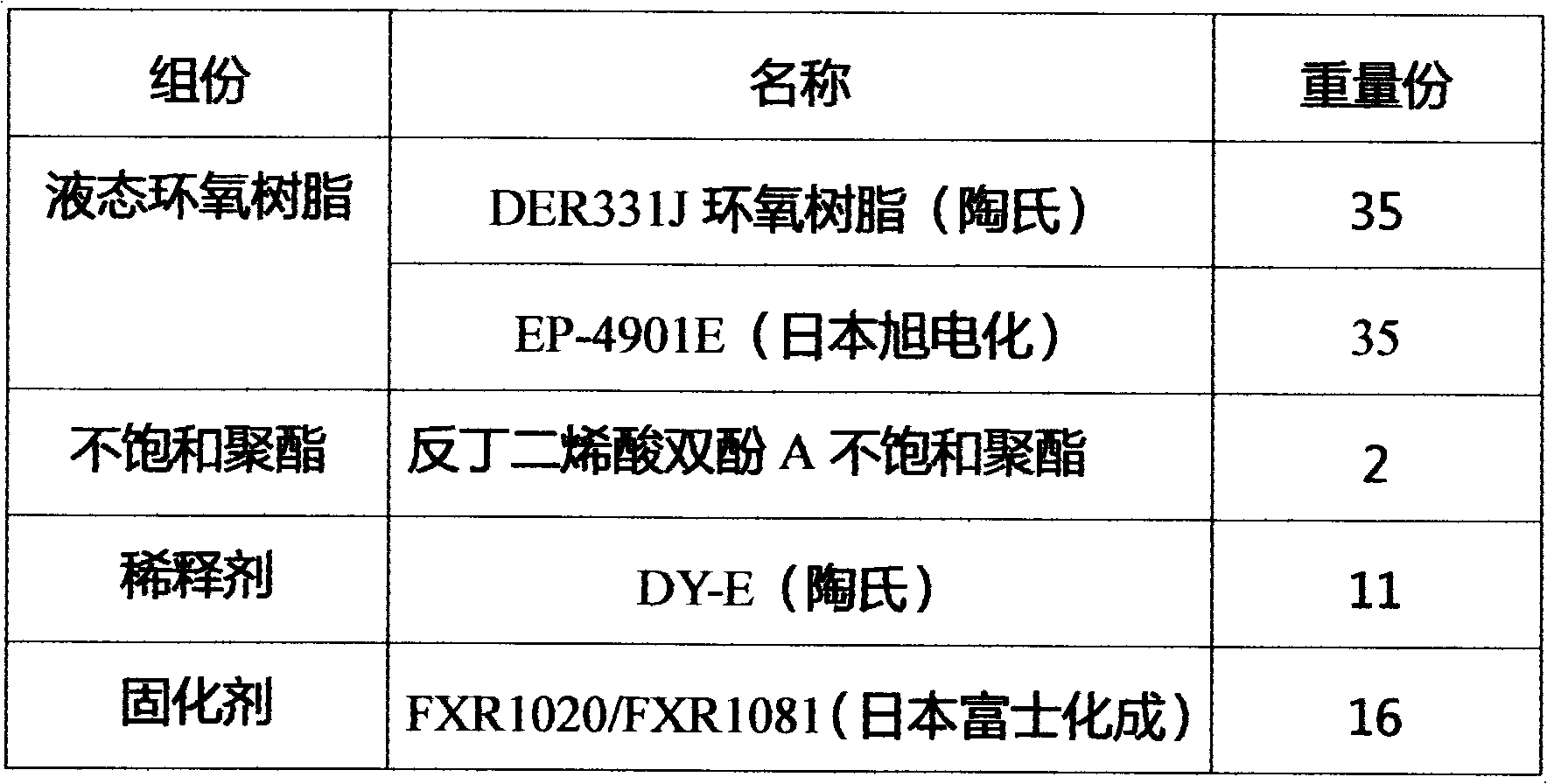

[0024] Embodiment 1: According to the following table and the following steps to prepare the rapid penetration underfill glue,

[0025] (1) Mix 35g DER331J epoxy resin (Dow), 35g EP-4901E (Japan Asahi Denka), 2g fumaric acid bisphenol A unsaturated polyester for pretreatment: heat up to 80°C and stir for 1.5 hours , cooled to 15°C;

[0026] (2) Add 16g of FXR1020 / FXR1081 curing agent (Fuji Kasei Japan) while stirring, continue stirring for 1 hour after adding, and control the temperature at 15°C;

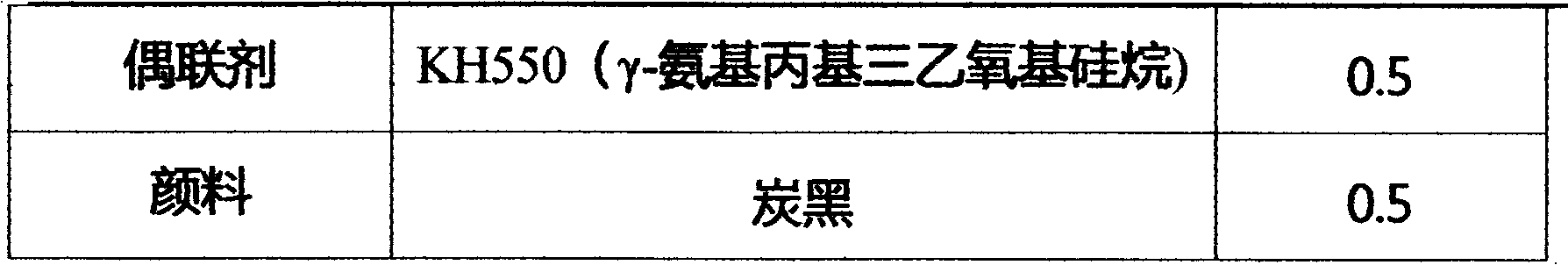

[0027] (3) Add 11g DY-E (Dow) diluent, 0.5g KH550 (γ-aminopropyltriethoxysilane) coupling agent and 0.5g carbon black, stir at 15°C for 1 hour to obtain rapid penetration Underfill glue.

[0028]

[0029]

Embodiment 2

[0030] Embodiment 2: According to the following table and the following steps to prepare rapid penetration underfill glue,

[0031] (1) Mix 10g alicyclic epoxy resin, 65g EP-4901E (Japan Asahi Denka), 6g fumaric acid bisphenol A unsaturated polyester for pretreatment, heat up to 100°C, stir for 2.5 hours, and cool down to 30°C;

[0032] (2) Add 18g of PN-H (Ajinomoto) curing agent while stirring, continue stirring for 1 hour after adding, and control the temperature at 30°C;

[0033] (3) Add 6g E-10 (Shell, glycidyl tert-carbonate) diluent, 0.8g KH550 (γ-aminopropyltriethoxysilane) coupling agent and 1g carbon black, and stir at 30°C for 1 Hours to get fast penetrating underfill.

[0034]

Embodiment 3

[0035] Embodiment 3: According to the following table and the following steps to prepare the rapid penetration underfill glue,

[0036] (1) Mix 15g DER331J (Dow), 40g EP-4901E (Japan Asahi Denka), 12g alicyclic epoxy resin and 3g fumaric acid bisphenol A unsaturated polyester for pretreatment, and heat up to 90°C degree, stirred for 2 hours, and cooled to 20°C;

[0037] (2) Add 15g of PN-H (Ajinomoto) curing agent while stirring, continue stirring for 1 hour after adding, and control the temperature at 25°C;

[0038] (3) Add 14.5g DY E (Dow, monoglycidyl ether of C12-C14 alcohol) diluent, 0.5g KH560 (glycidoxytrimethoxysilane) coupling agent, and stir at 20°C for 1 hour Get fast penetrating underfill.

[0039]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com