Glass mold die structure for manufacturing glass container

A technology of glass molds and glass containers, which is applied in the direction of manufacturing tools, glass molding, glass manufacturing equipment, etc., can solve the problems of low spray welding efficiency, cracking of the spray welding layer, and increased mold cost, so as to improve manufacturing efficiency and reduce The effect of working strength and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

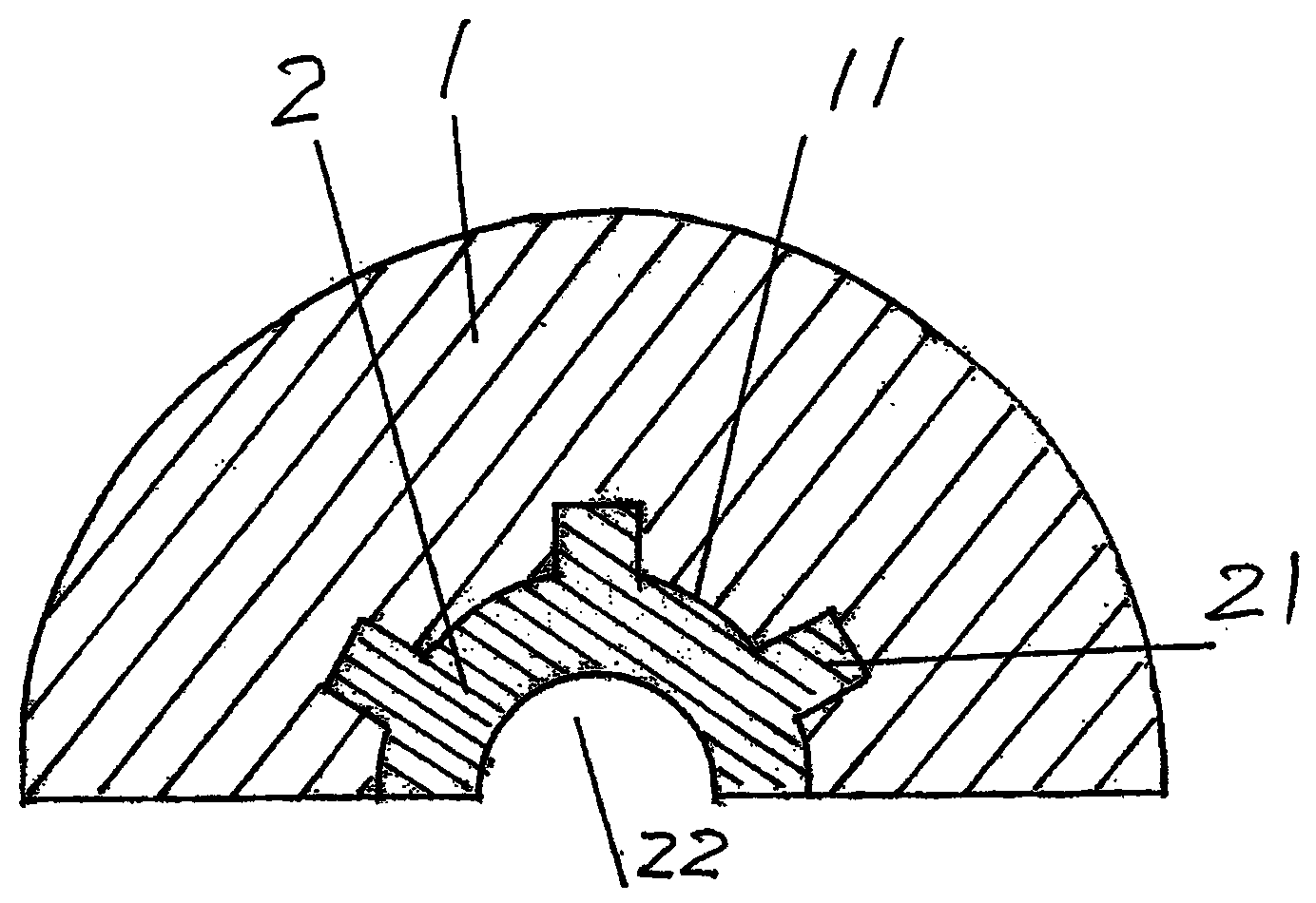

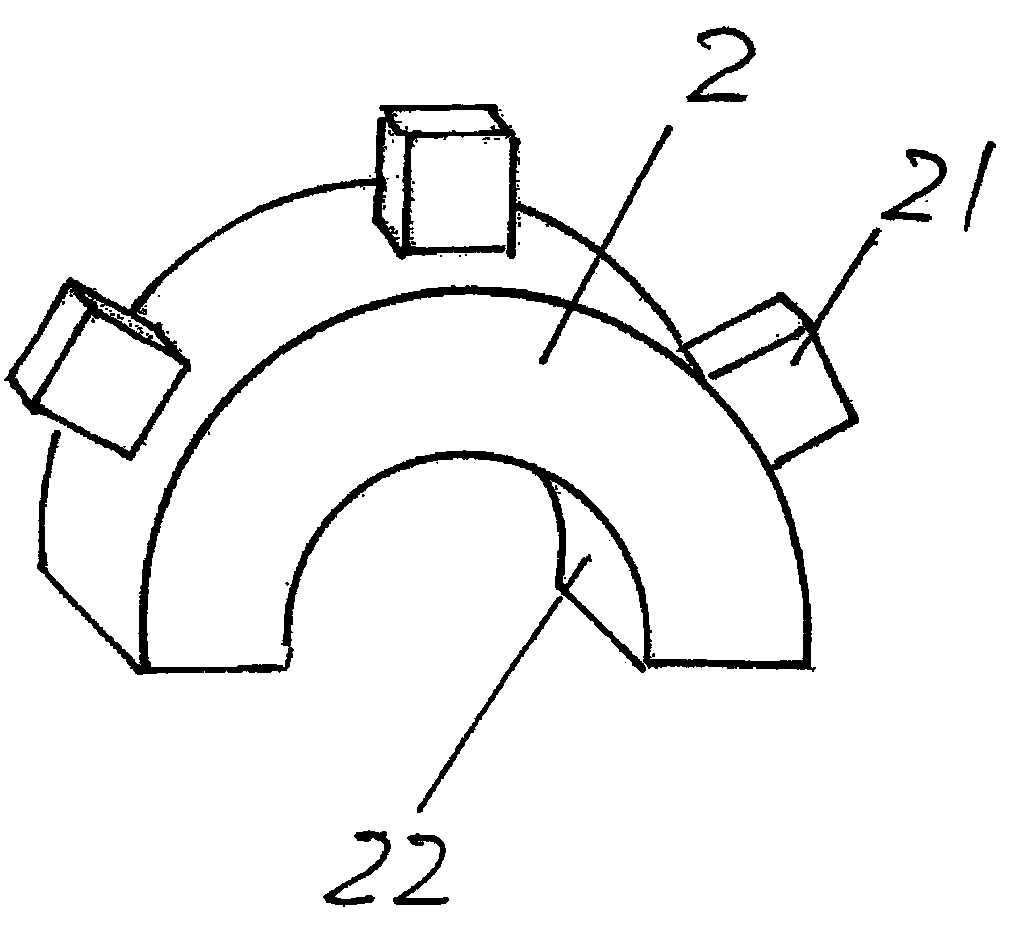

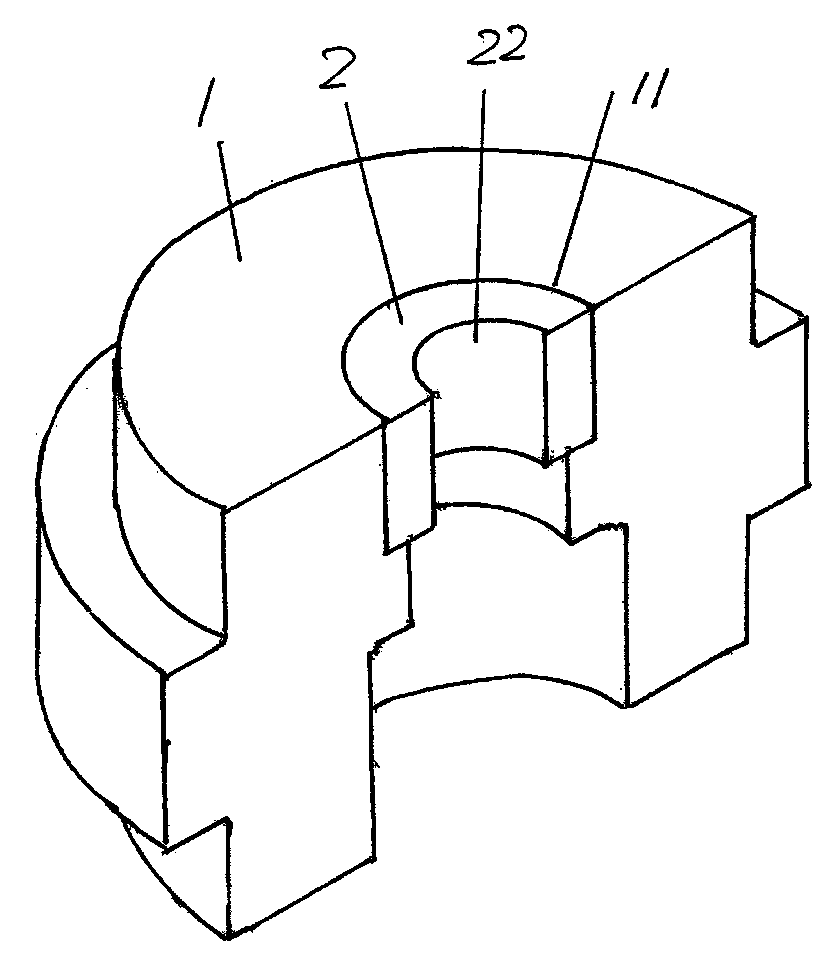

[0022] See figure 1 , figure 2 and image 3 The die body 1 is combined with, that is, fixed at the position of the bottle mouth of the bottle mould, when in use, the die body 1 is shaped as a semicircle and has a die body cavity 11, a wear-resistant body 2 ( figure 2 (shown) are fixed with the die body cavity 11 of the die body 1 in a mortise-and-mortise manner when the die body 1 is formed as an independent component. The concept of forming the die body 1 described here is pouring forming.

[0023] As shown in the figure, on the side of the wear body 2 facing the die body 1 , that is, on the side facing away from the wear body cavity 22 , there are a set of tenons 21 extending radially at intervals. In this embodiment, although the number of a set of tenons 21 is shown as three, it should obviously not be limited by the number shown in the figure, and the wear-resistant body 2 and the die body 1 are formed into one body by a set of tenons 21 .

[0024] When p...

Embodiment 2

[0028] As shown in the figure, only the distance between adjacent tenons 21 is changed to 6.5mm, the thickness of die body 1 is changed to 40mm, the thickness of wear-resistant body 2 is changed to 10mm, the length of tenon 21 is 30mm and The cross-sectional shape of tenon 21 is circular. All the other are the same as the description to embodiment 1.

Embodiment 3

[0030] The picture is omitted, only the distance between adjacent tenon 21 is changed to 6mm, the thickness of die body 1 is changed to 20mm, the thickness of wear-resistant body 2 is changed to 8mm, the length of tenon 21 is 12mm and The cross-sectional shape of tenon 21 is an equilateral hexagon. All the other are the same as the description to embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com