Fixing structure of motor shaft for electric vehicle

A technology for motor shafts and electric vehicles, which is applied to electric vehicles, motors, motor vehicles, etc., can solve the problems of weakening the tightening force of nuts that fasten motor shafts, and achieve the effect of easy position alignment and protection of wiring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

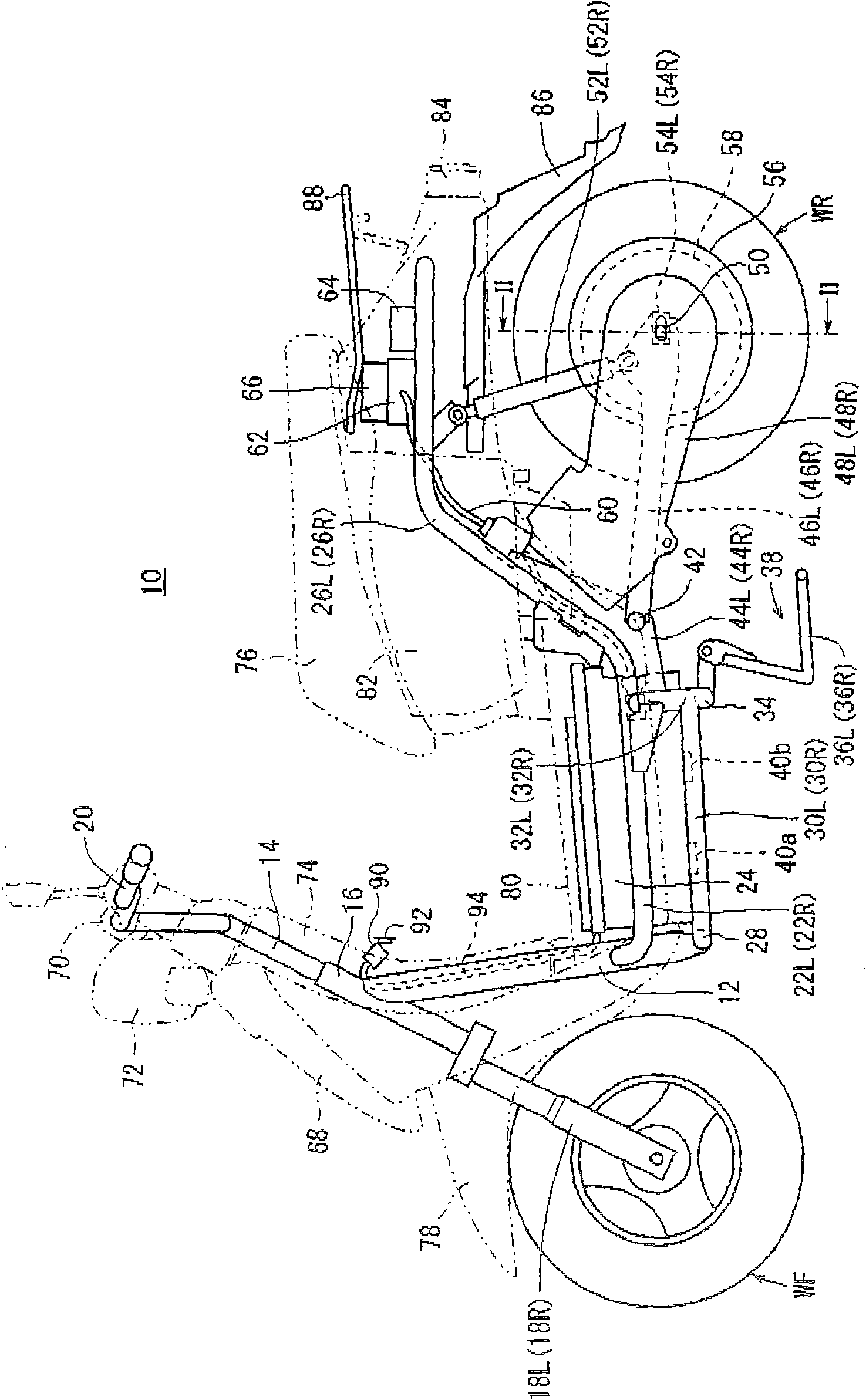

[0041] figure 1 It is a side view of an electric motorcycle (electric vehicle) 10 . It should be noted that, for the mechanisms or components provided on the left and right sides of the vehicle body, "L" is added to the reference symbols of the mechanisms or components on the left side, and "L" is added to the reference symbols of the mechanisms or components on the right side. R".

[0042] A head pipe 16 is coupled to an upper end portion of the main frame 12 of the electric motorcycle 10 , and the head pipe 16 pivotally supports the steering rod 14 so as to be rotatable. A pair of front forks 18L and 18R that rotatably support the front wheel WF are attached to the steering rod 14 , and the front wheel WF can be steered by a handle 20 attached to the upper portion of the steering rod 14 .

[0043] A pair of left and right upper frames 22L, 22R are connected to the lower portion of the main frame 12 , and the upper frames 22L, 22R extend obliquely downward from the connecti...

no. 2 approach

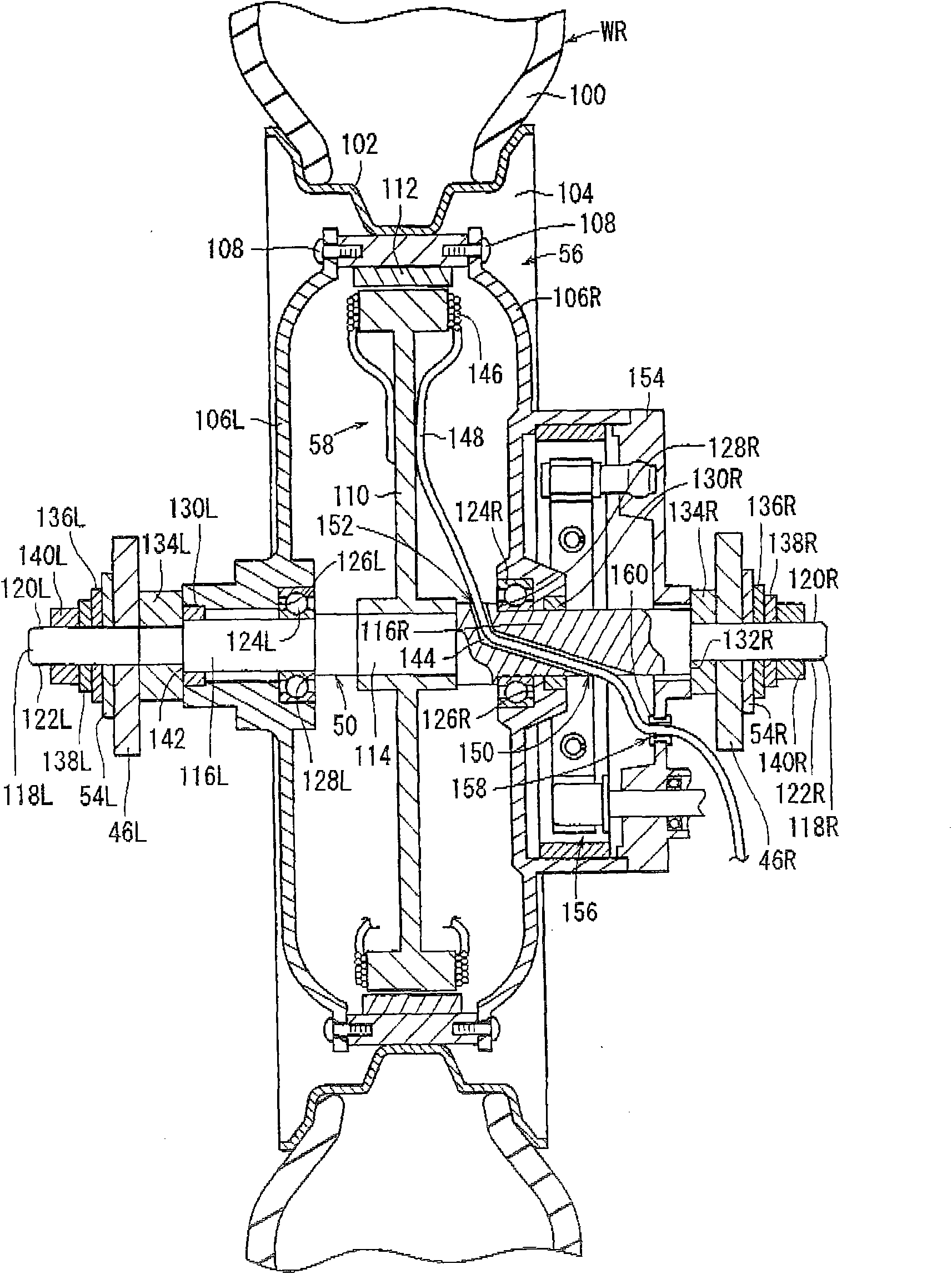

[0072] Next, a fixing structure of the motor shaft 50 for the electric motorcycle 10 will be described. Figure 5 yes means figure 1 The enlarged view of the main part of the shown swing arm 46L, Fig. 6 shows figure 1 A diagram of the stop mechanism 54L is shown. Figure 6A is the front view of the stop mechanism 54L, Figure 6B is the rear view of the stop mechanism 54L, Figure 6C It is a top view of the stopper mechanism 54L.

[0073] The fastening portion 118L of the motor shaft 50 is a portion for fastening to the vehicle body side with the nut 140L, and has an upper fastening surface 120L and a lower fastening surface 122L as described above. The fastening surfaces 120L, 122L are parallel to the front-rear direction of the vehicle body. The swing arm 46L has an arm portion 200 and an end peace portion 202. The end peace portion 202 is provided with an engaging opening 204 that matches the shape of the fastening portion 118L to restrict the rotation (rotation) of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com