Molecular sieve adsorption tower for nitrogen making equipment

A technology of molecular sieves and adsorption towers, which is applied in the field of nitrogen production equipment and can solve problems such as the influence of nitrogen production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

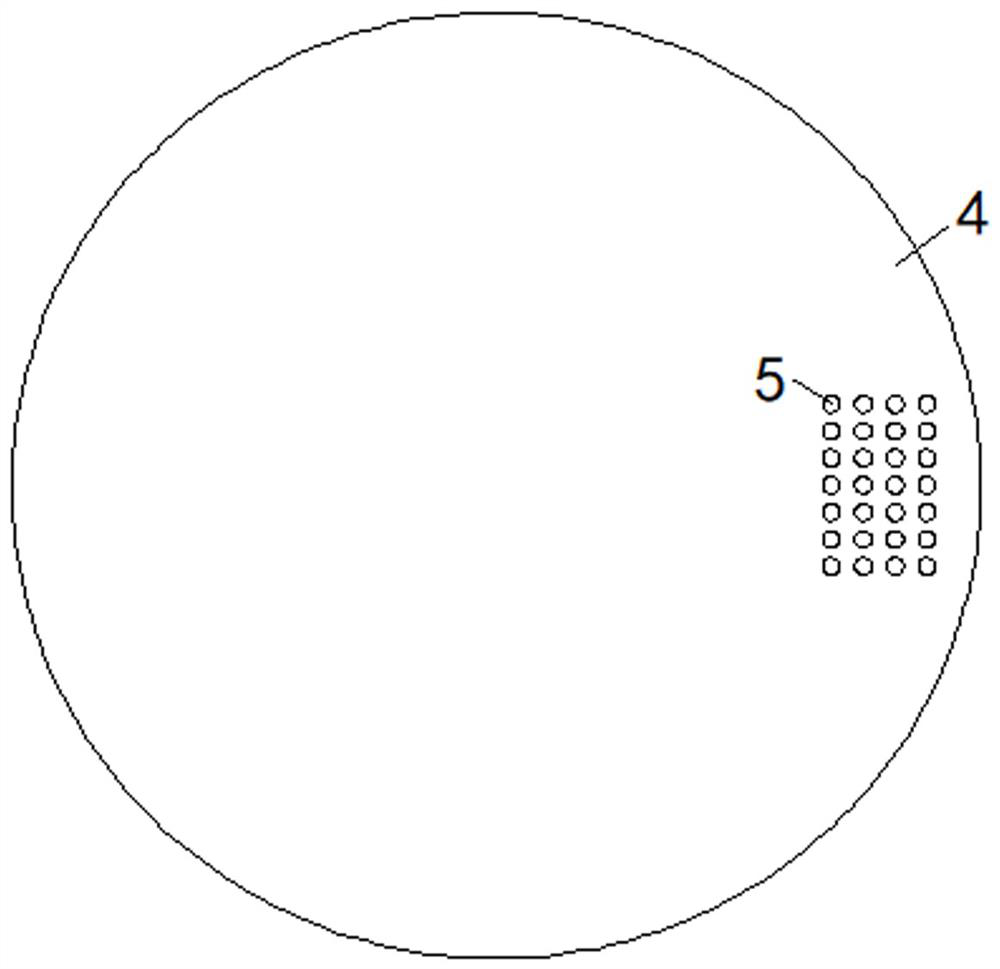

[0031] The embodiment of the present invention provides a molecular sieve adsorption tower used in nitrogen making equipment, such as Figure 1-Figure 10 As shown, it includes a main tower body 1, the lower end of the main tower body 1 is fixedly connected with a plurality of support rods 2, the lower ends of the plurality of support rods 2 are fixedly connected with the support plate 3, and a molecular sieve adsorption assembly is arranged in the main tower body 1, wherein , the molecular sieve adsorption assembly includes two symmetrically arranged first barrier plates 4 fixedly connected in the main tower body 1, and a plurality of through holes 5 distributed in an array are opened on the two first barrier plates 4. The main tower body 1 The power motor 7 is fixedly connected through a plurality of first connecting rods 6 , the output end of the power motor 7 is fixedly connected with a first rotating shaft 8 , and the side surface of the first rotating shaft 8 is fixedly co...

Embodiment 2

[0036] combine Figure 4 , Figure 5 , Figure 7 , Figure 8 , Figure 9 and Figure 10 In this embodiment, on the basis of Embodiment 1, the molecular sieve adsorption plate 23 is provided with sieve holes 181, the molecular sieve adsorption plate 23 is provided with a molecular sieve adsorption layer, and the molecular sieve adsorption plate 23 is fixedly connected with a second handle 182, and the connecting unit includes A plurality of first clamping rods 183 are symmetrically arranged on the molecular sieve adsorption plate 23 , the third blocking plate 10 is provided with a first clamping groove 184 that cooperates with the first clamping rods 183 , and the first clamping groove 184 is slidably connected There is a first snap block 185, the side of the first snap block 185 is connected to the first snap slot 184 through a first spring 186 for providing elastic force, the side of the first snap block 185 is set as an inclined surface 187, A fourth blocking plate 189 ...

Embodiment 3

[0040] combine Figure 4 and Figure 5 , In this embodiment, on the basis of Embodiment 2, the side surface of the main tower body 1 is provided with an anti-blocking unit.

[0041] The anti-blocking unit includes a first box body 211, the first box body 211 is fixedly connected to the side surface of the main tower body 1, the first box body 211 is arranged through the main tower body 1, and the side surface of the first box body 211 is fixedly connected with an anti-blocking body The air cylinder 212, the output end of the anti-blocking cylinder 212 is fixedly connected with an anti-blocking plate 213, and the side surface of the anti-blocking plate 213 is fixedly connected with a plurality of anti-blocking heads 214 distributed in an array.

[0042] When the above-mentioned anti-blocking unit is actually used, the push-out portion of the anti-blocking cylinder 212 drives the anti-blocking head 214 provided on the anti-blocking plate 213 to contact the sieve holes 181 provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com