Ceramic roller molding process

A technology of ceramic rollers and molding process, applied in ceramic extrusion dies and other directions, can solve the problems of easy wear of propeller blades, high maintenance cost, complex structure, etc., and achieve the effect of simple structure, low maintenance cost, and solving complex structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

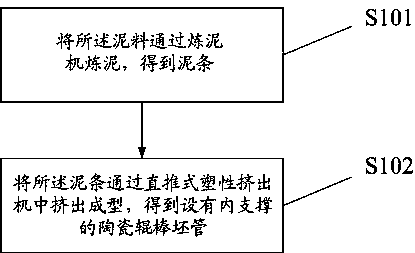

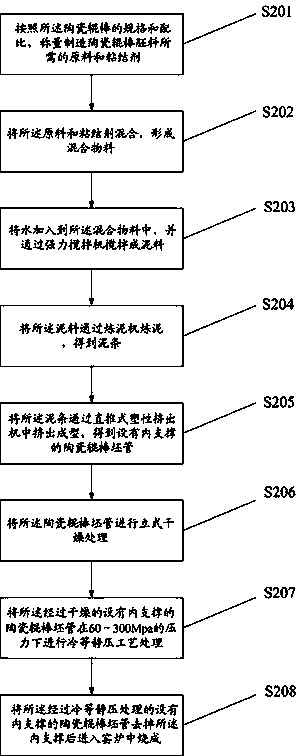

Method used

Image

Examples

Embodiment 1

[0174] Production of ceramic rollers with a specification of ?60mm. According to the ratio required for the manufacture of ceramic rollers, weigh 100kg of ceramic roller raw materials and 2kg of carboxymethyl cellulose, and add them to a strong mixer and mix for about 3 to 8 minutes. After mixing evenly, add water and stir for 10 to 20 minutes. , to get mud. The mud material is granulated and smelted twice through a direct-push mud mixer, and the mud is smelted for the first time to obtain a mud bar with a diameter of 6mm. The mud bars obtained by the first mud refining are put into a direct-push mud mixer for the second mud refining to obtain mud bars with a diameter of 4mm. Put the mud strips that have undergone secondary mud refining into the vacuum silo of the direct-push extruder, extract the vacuum degree -0.08MPa, set the extrusion molding pressure to 1500~2000KN, and control the extrusion molding speed at 18 m / minute. The shape of the mold at the discharge port of ...

Embodiment 2

[0176] Production of ceramic rollers with a specification of ?60mm. According to the ratio required for the manufacture of ceramic rollers, weigh 100kg of ceramic roller raw materials and 2kg of carboxymethyl cellulose, and add them to a strong mixer and mix for about 3 to 8 minutes. After mixing evenly, add water and stir for 10 to 20 minutes. , to get mud. The mud is smelted by a screw mud mixer, and the mud is smelted for the first time to obtain a mud bar with a diameter of 10mm. Put the mud bars obtained from the first mud refining into the screw mud mixer for the second mud refining to obtain mud bars with a diameter of 8mm. Put the mud strips that have undergone secondary mud refining into the vacuum silo of the direct push extruder, extract the vacuum degree -0.16MPa, set the extrusion molding pressure to 800~1300KN, and control the extrusion molding speed at 15 m / minute. The shape of the mold at the discharge port of the extruder is ring-shaped, with an outer diam...

Embodiment 3

[0178] Production of ceramic rollers with a specification of ?60mm. According to the ratio required for the manufacture of ceramic rollers, weigh 100kg of ceramic roller raw materials and 2kg of carboxymethyl cellulose, and add them to a strong mixer and mix for about 3 to 8 minutes. After mixing evenly, add water and stir for 10 to 20 minutes. , to get mud. The mud material is granulated and smelted twice through a direct-push mud mixer, and the mud is smelted for the first time to obtain a mud bar with a diameter of 6mm. The mud bars obtained by the first mud refining are put into a direct-push mud mixer for the second mud refining to obtain mud bars with a diameter of 4mm. Put the mud strips that have undergone secondary mud refining into the vacuum silo of the direct-push extruder, extract the vacuum degree -0.03MPa, set the extrusion molding pressure to 3500~4000KN, and control the extrusion molding speed at 20 m / minute. The shape of the mold at the discharge port of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com