Food weight-fixed cutting method and food cutting machine

A cutting method and cutting machine technology are applied in the field of fixed weight cutting of food materials, food fixed weight cutting, and food fixed weight cutting machines, which can solve the problems of low processing efficiency, not easy, waste of food materials, etc. The effect of reducing processing costs and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A food fixed-weight cutting method, which is carried out according to the following steps: ①Use a laser light source and a camera to collect images of food materials conveyed on a conveyor belt; ②Use a computer equipped with an image processing and fixed-weight calculation system to collect images Carry out image processing and calculate the length of fixed-weight cutting; ③When the length of fixed-weight cutting is reached, the cutting device will implement cutting.

Embodiment 2

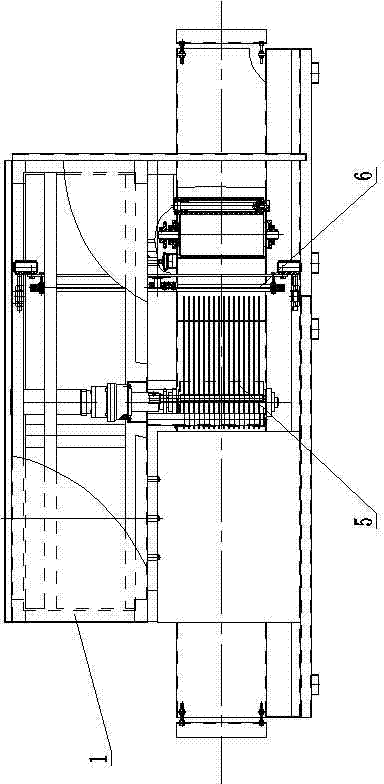

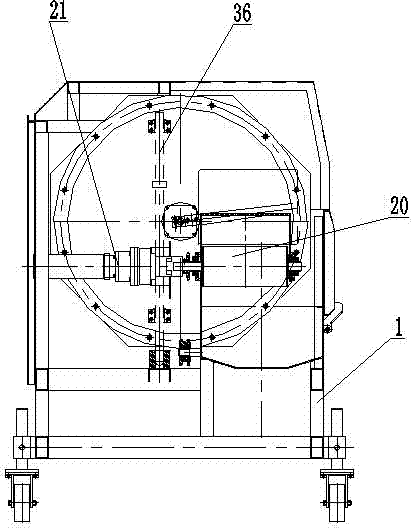

[0037] as attached Figure 1-4As shown, a food cutting machine includes a frame 1, the frame 1 is a welded frame structure, and the frame 1 is provided with a mesh belt conveying device I2 for conveying food materials along its length direction and for output Mesh belt conveying device II7 for the cut food, a laser light source 3 and an industrial camera 4 are provided above the mesh belt conveying device I2 corresponding to the food placed on the conveying mesh belt, and the laser light source 3 and the industrial camera 4 are respectively connected to the frame On the top, the signal output end of the industrial camera 4 is electrically connected with a computer equipped with an image processing and fixed weight calculation system. A cutting device 6 fixed on the frame 1 is provided in the gap between the mesh belt conveying device I2 and the mesh belt conveying device II7, and a cutting device 6 connected to the frame 1 is provided on the feeding side of the cutting device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com