Roll gap of multi-roll straightener

A technology for multi-roll straightening and straightening machine rolls, which is applied in the field of steel plate straightening, can solve the problems of being unsuitable for the new straightening roll gap setting method, etc., and achieves a simple and practical model, eliminates residual stress, and improves plate shape quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

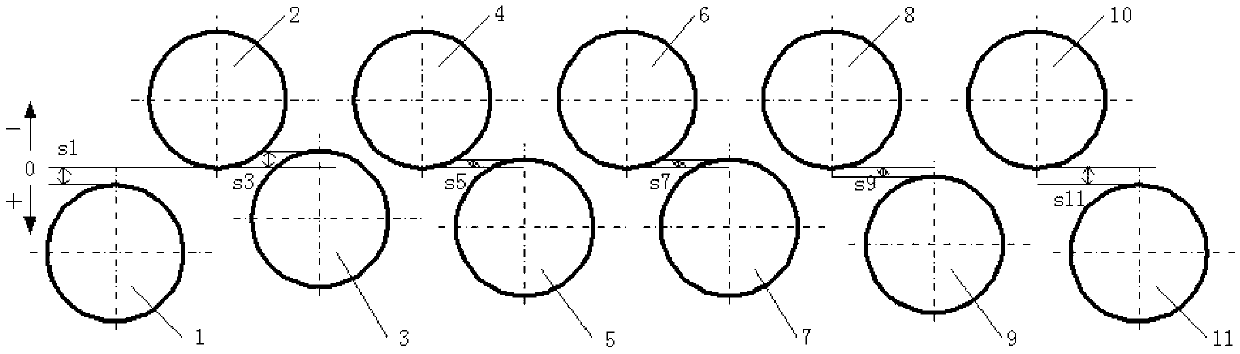

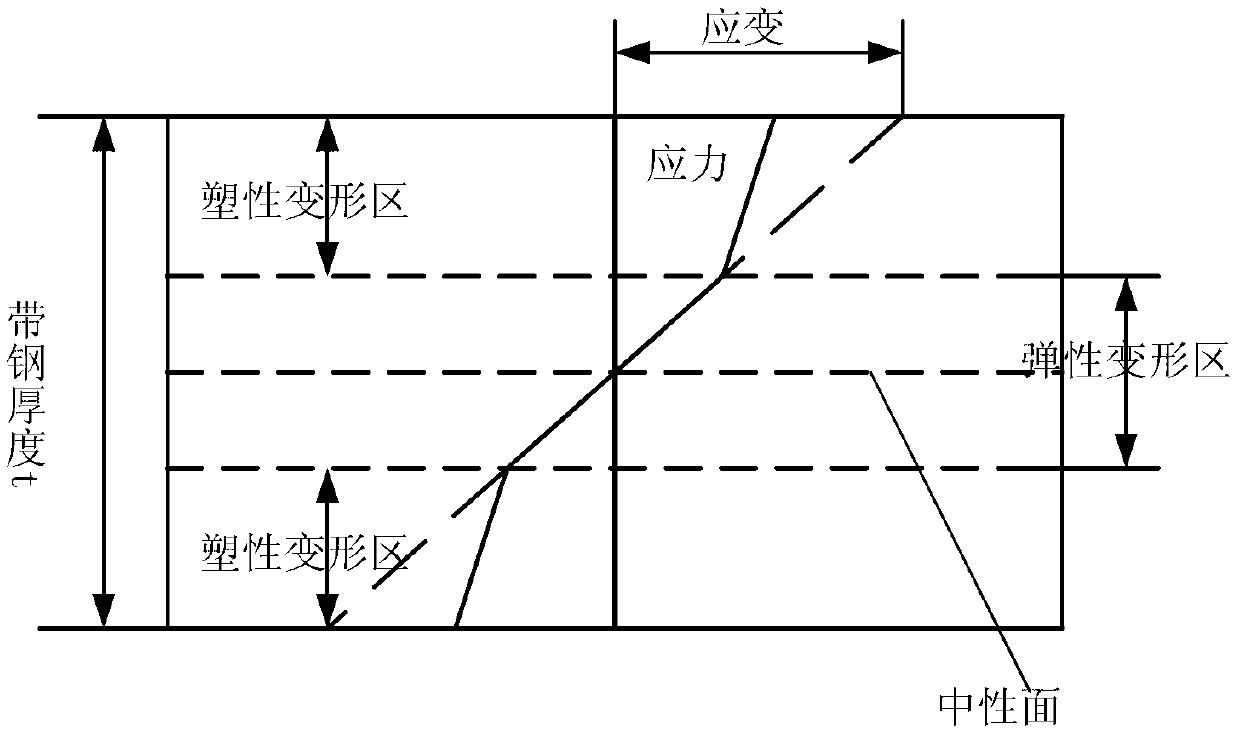

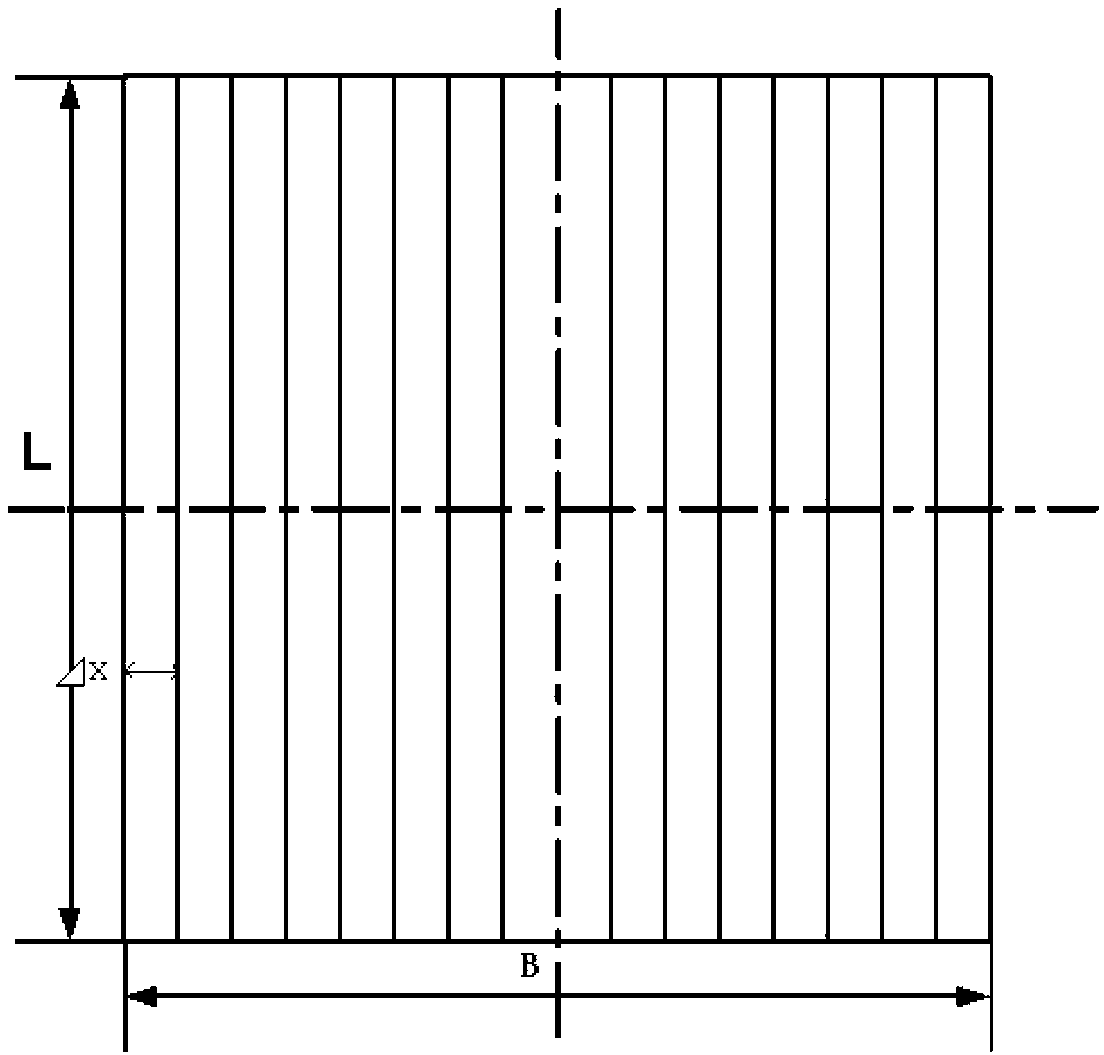

[0022] Before the high-strength plate is straightened, it is firstly flattened and annealed, and the production cost is relatively high. In order to better control the shape quality of cross-cut plates for high-strength steel and ship plates, Shougang Qiangang completed the construction of a cross-cut production line in 2010 and put it into production. The hot-rolled strip multi-roll leveling unit of Shougang Qiangang Co., Ltd. is composed of a 7-roll rough leveler and an 11-roll fine leveler. The equipment is designed and manufactured by SMS. The equipment structure has the functions of horizontality, forward and backward inclination, transverse bending, and the lower straightening roller can individually adjust the roll gap. The lower straightening rollers are independently adjustable, and the required straightening roll gap is achieved through the adjustment of an electronic adjustment system. The roll gap is set according to parameters such as plate thickness and material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com