Device for regenerating spherical hydroxyapatite for defluorination

A technology of hydroxyapatite and regeneration device, applied in filter regeneration, petroleum industry, water/sludge/sewage treatment, etc., can solve the problems of unstable regeneration effect, high economic cost, long consumption time, etc. effect of regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

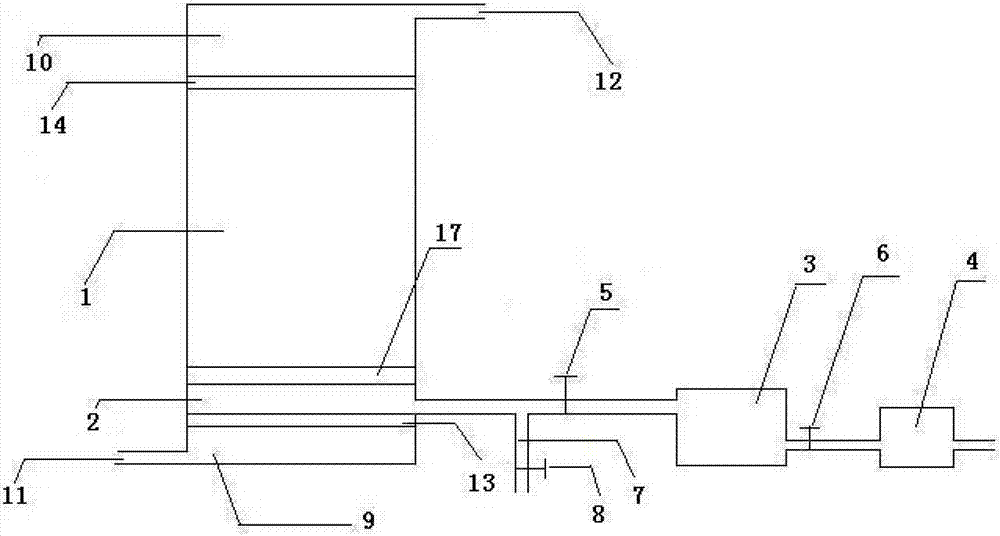

[0029] Spherical hydroxyapatite regeneration device, see figure 1 with 2 , including a reactor 1 with an open top, a steam distribution device 2 , a steam generating device 3 and a water softener 4 .

[0030] Wherein, the steam distributing device 2 is arranged at the bottom of the reactor 1; the steam distributing device 2, the steam generating device 3 and the water softener 4 are sequentially connected, and a first valve 5 is arranged between the steam distributing device 2 and the steam generating device 3; the steam generating device A second valve 6 is provided between the water softener 3 and the water softener 4 . A water outlet pipe 7 is provided between the steam distribution device 2 and the first valve 5 , and a third valve 8 is provided on the water outlet pipe 7 .

[0031] The steam distribution device 2 is a "well"-shaped perforated pipe; the steam can directly enter the reactor through the small holes on the distribution device to realize the heating and rege...

Embodiment 2

[0033] Spherical hydroxyapatite regeneration device, see image 3 and Figure 4 , including the water distribution layer 9, the first water distribution plate 13, the steam distribution device 2, the filter layer 17, the reactor 1, the second water distribution plate 14 and the water outlet layer 10 connected in sequence from bottom to top, and the side wall of the water distribution layer 9 is provided with an inlet The water outlet 11 is provided with a water outlet 12 on the side wall of the water outlet layer 10 .

[0034] It also includes a steam generator 3 and a water softener 4, the steam distribution device 2, the steam generator 3 and the water softener 4 are sequentially connected, and a first valve 5 is arranged between the steam distribution device 2 and the steam generator 3; the steam generator 3 and the steam generator 3 A second valve 6 is provided between the water softeners 4 . A water outlet pipe 7 is provided between the steam distribution device 2 and t...

Embodiment 3

[0041] Spherical hydroxyapatite regeneration device, see Figure 5, including the water distribution layer 7, the first water distribution plate 11, the steam distribution device 2, the filter layer 17, the reactor 1, the second water distribution plate 14, the quartz sand filter material layer 15, and the third water distribution plate 16 connected sequentially from bottom to top And the water outlet layer 10, the side wall of the water distribution layer 9 is provided with a water inlet 11, and the side wall of the water outlet layer 10 is provided with a water outlet 12.

[0042] It also includes a steam generator 3 and a water softener 4, the steam distribution device 2, the steam generator 3 and the water softener 4 are sequentially connected, and a first valve 5 is arranged between the steam distribution device 2 and the steam generator 3; the steam generator 3 and the steam generator 3 A second valve 6 is provided between the water softeners 4 . A water outlet pipe 7 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com