Method and system for jointly desulfuration, denitration and demercuration by activated coke of moving bed

A technology of desulfurization, denitrification and mercury removal, and bed activated coke, which is applied in the field of moving bed active coke combined with desulfurization, denitrification and demercuration, can solve the problems of increasing bed resistance, reducing denitrification efficiency, and high desulfurization efficiency, so as to prevent system blockage and reduce system Investment, reduce the effect of system clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

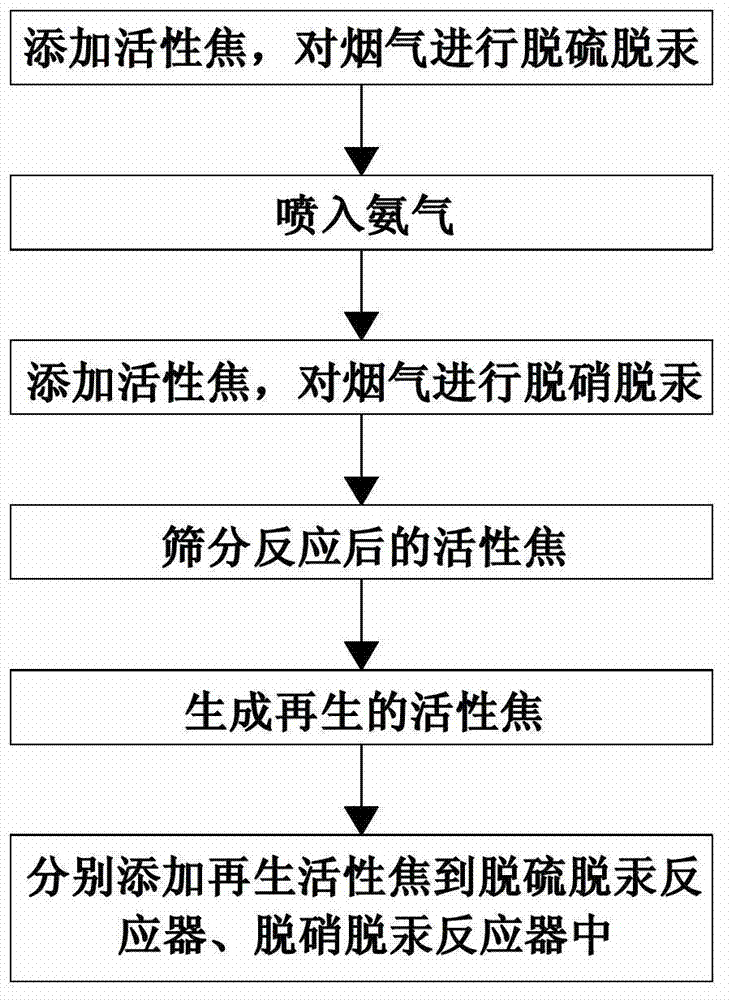

[0050] Embodiment 1 of the present invention: a process of moving bed activated coke combined with desulfurization, denitrification and demercuration, such as figure 1 shown, including the following steps:

[0051] 1. The weighing feeding device puts the active coke into the desulfurization and mercury removal reactor and the denitrification and mercury removal reactor respectively, the flue gas passes through the desulfurization and mercury removal reactor for desulfurization and mercury removal, and ammonia gas is sprayed into the outlet flue of the desulfurization and mercury removal reactor , fully mixed with the flue gas at the outlet, the mixed flue gas passes through the denitration and demercuration reactor for denitrification and demercuration, and the obtained net flue gas is discharged from the chimney;

[0052] 2. The activated coke after the reaction enters the activated coke screening device to screen out the dust adsorbed by the activated coke during the desulfu...

Embodiment 2

[0063] Embodiment 2 of the present invention: a process of moving bed activated coke combined with desulfurization, denitrification and demercuration, such as figure 1 shown, including the following steps:

[0064]1. The weighing feeding device puts the active coke into the desulfurization and mercury removal reactor and the denitrification and mercury removal reactor respectively, the flue gas passes through the desulfurization and mercury removal reactor for desulfurization and mercury removal, and ammonia gas is sprayed into the outlet flue of the desulfurization and mercury removal reactor , fully mixed with the flue gas at the outlet, the mixed flue gas passes through the denitration and demercuration reactor for denitrification and demercuration, and the obtained net flue gas is discharged from the chimney;

[0065] 2. The activated coke after the reaction enters the activated coke screening device to screen out the dust adsorbed by the activated coke during the desulfur...

Embodiment 3

[0076] Embodiment 3 of the present invention: a process of moving bed activated coke combined with desulfurization, denitrification and demercuration, such as figure 1 shown, including the following steps:

[0077] 1. The weighing feeding device puts the active coke into the desulfurization and mercury removal reactor and the denitrification and mercury removal reactor respectively, the flue gas passes through the desulfurization and mercury removal reactor for desulfurization and mercury removal, and ammonia gas is sprayed into the outlet flue of the desulfurization and mercury removal reactor , fully mixed with the flue gas at the outlet, the mixed flue gas passes through the denitration and demercuration reactor for denitrification and demercuration, and the obtained net flue gas is discharged from the chimney;

[0078] 2. The activated coke after the reaction enters the activated coke screening device to screen out the dust adsorbed by the activated coke during the desulfu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com