Ultramicro sewage filter with backwashing function and method thereof

A sewage filter and ultra-fine technology, applied in fixed filter element filters, chemical instruments and methods, filtration and separation, etc., can solve the problems of harsh use conditions, high use costs, and no resistance to oil pollution, and achieve low operating costs. Reliable and cost-effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

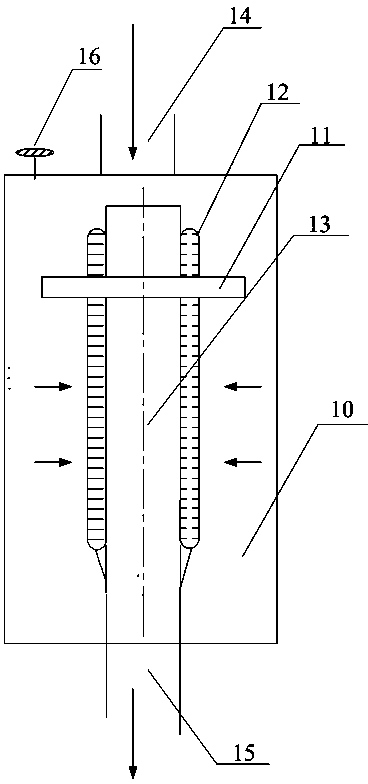

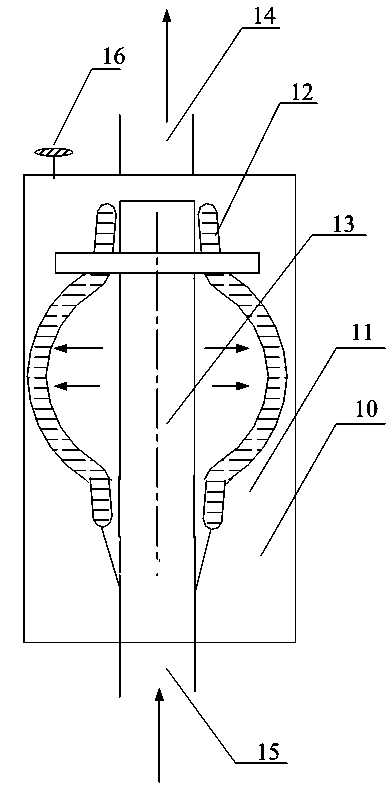

[0030] like figure 1 and figure 2 A kind of high-precision oil-water separation device shown comprises: a pressure vessel tank 10, at least one filter element is arranged in the pressure vessel tank 10, a water inlet 14 is arranged on the top of the pressure vessel tank 10, and the pressure vessel tank 10 The bottom of the tank 10 is provided with a water outlet 15 connected to the filter element.

[0031] The filter element 10 includes a perforated hard tube 13 and a fiber bundle 12 as a filter medium disposed on the perforated hard tube 13 , and the fiber bundle 12 is bound on the perforated hard tube 13 by a binding belt 11 .

Embodiment 2

[0033] Filtration treatment of sewage containing talcum powder powder: 1. Continuously pump the sewage to be treated into the pressure vessel through the water inlet; 2. Sewage flows from the outside of the fiber bundle of the filter element through the The fiber bundles enter the perforated hard pipe, so that a pressure difference is generated between the outside and the inside of each fiber bundle, and the fiber bundles are in a compacted state, and the filtered clean water passes through the pores between the fiber bundles and enters the After perforating the hard pipe, it is discharged from the water outlet; and the filtered suspended matter whose particle size is smaller than or equal to the pores formed between the fibers is adsorbed on the surface of the fiber bundle, because its particle size is larger than the pores formed between the fibers And be intercepted, clean water flows out from described water outlet.

[0034] The particle size of the powder contained in the...

Embodiment 3

[0036] Filtration treatment of abrasive emulsion wastewater in a machining factory: firstly, the fibers were subjected to hydrophilic surface treatment, and then the fiber bundles were bound with perforated hard pipes with binding tapes. The water treatment method was the same as that in Example 2. The sewage contained Suspended matter 1500ppm, containing highly emulsified oil 8000ppm, carry out continuous filtration with the filter prototype that the present invention makes, and the treatment water rate is 0.5 ton / hour. After testing, the treated effluent contains 0.9ppm of suspended solids. After running for 1 hour, the pressure rose to 0.3 MPa, and the flow was restored after starting backwashing. The backwashing method was the same as in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com