Seedling-stage film stripping machine

A film peeling machine and seedling stage technology, applied in the field of seedling film peeling machine, can solve the problems of difficult film peeling, aggravation of pests and diseases, poor lodging resistance and stress resistance, etc. novel effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

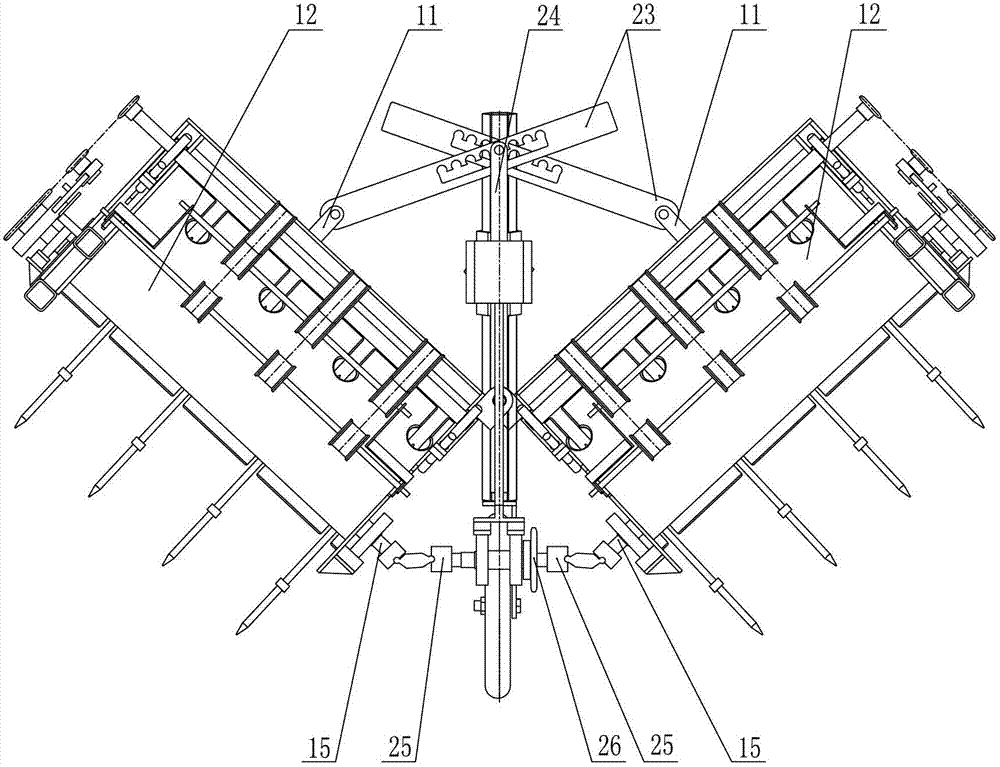

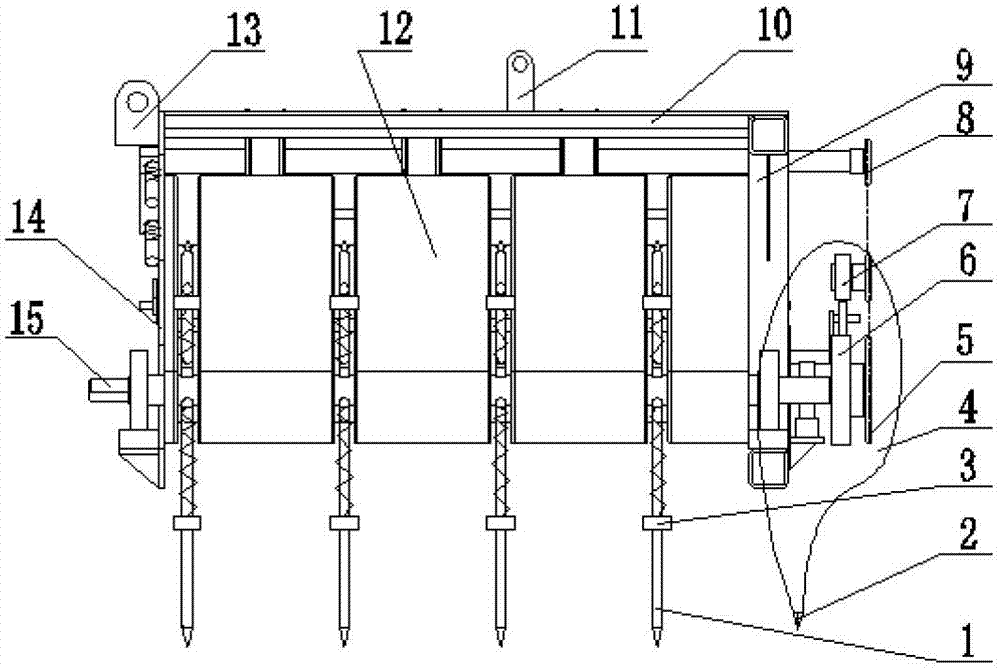

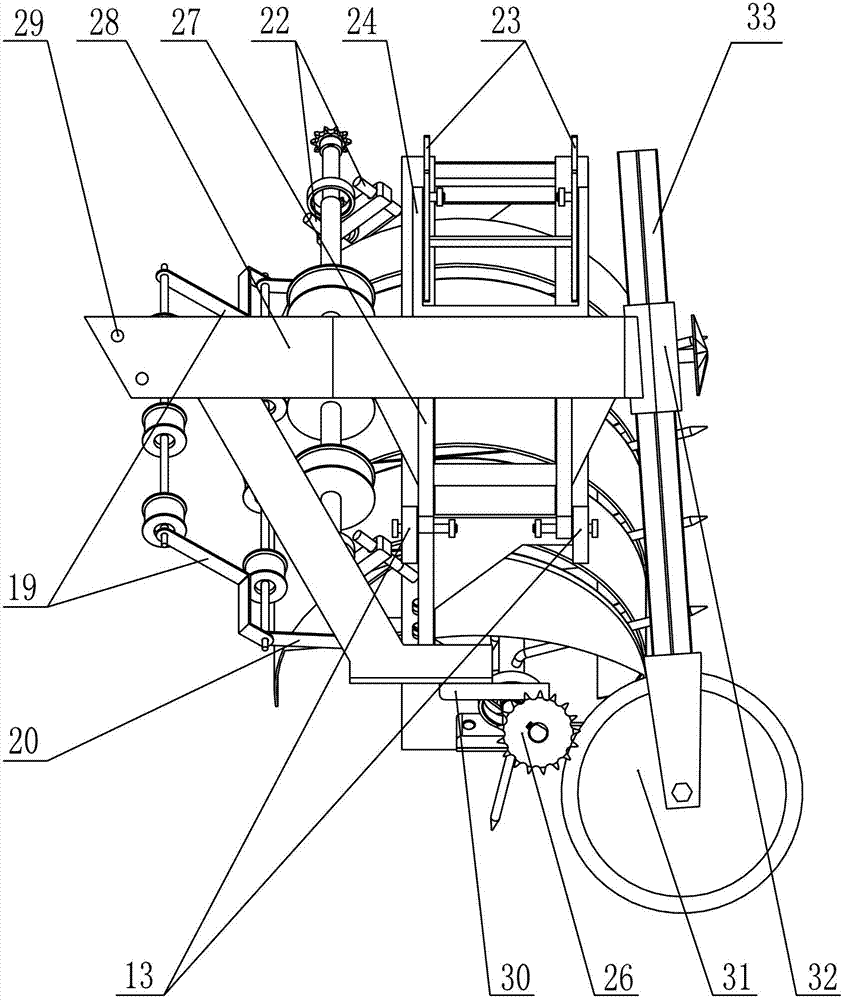

[0019] Below in conjunction with accompanying drawing, describe in detail the specific implementation of a kind of film removing machine at seedling stage.

[0020] like Figures 1 to 4 As shown, a kind of film-removing machine at seedling stage, taking the right side of the film-removing mechanism on both sides as an example, such as figure 1 As shown, the frame includes a frame beam 28, an adjusting rod 33, an underframe and an adjusting arm fixed mount 24, the adjusting rod is installed on the underframe, and the depth-gauge wheel 31 is installed on the underframe, and the frame beam passes through The height adjuster 32 is installed on the adjusting rod 33, the adjusting arm fixing bracket 24 is installed on the upper side of the frame cross beam 28, and the supporting ear fixing bracket 13 is installed on the lower side, the middle part of the cross beam 10 of the film peeling mechanism A suspension short arm 11 is provided, and one end of the crossbeam 10 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com