Device for introducing a force into tension members made of fiber-reinforced plastic flat strip lamella

A fiber reinforced, tension member technology, used in building components, connecting components, building reinforcements, etc., can solve the problems of high cost, insufficient stress distribution, limited efficiency of force introduction into tension members, etc., and achieves simple manufacturing and use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

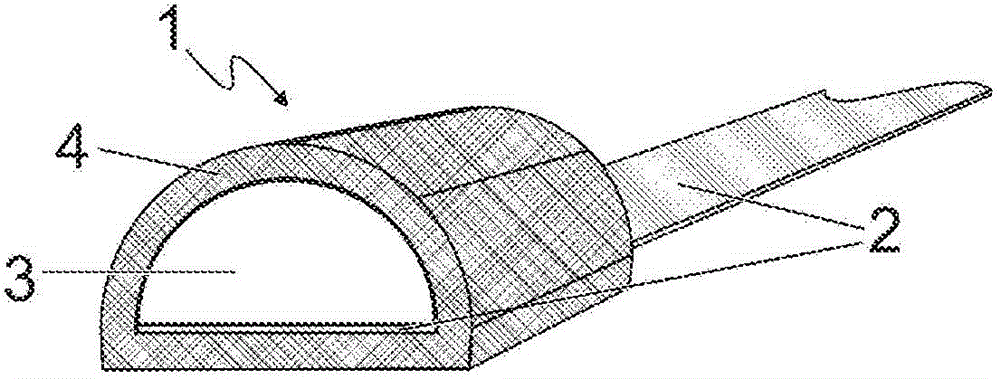

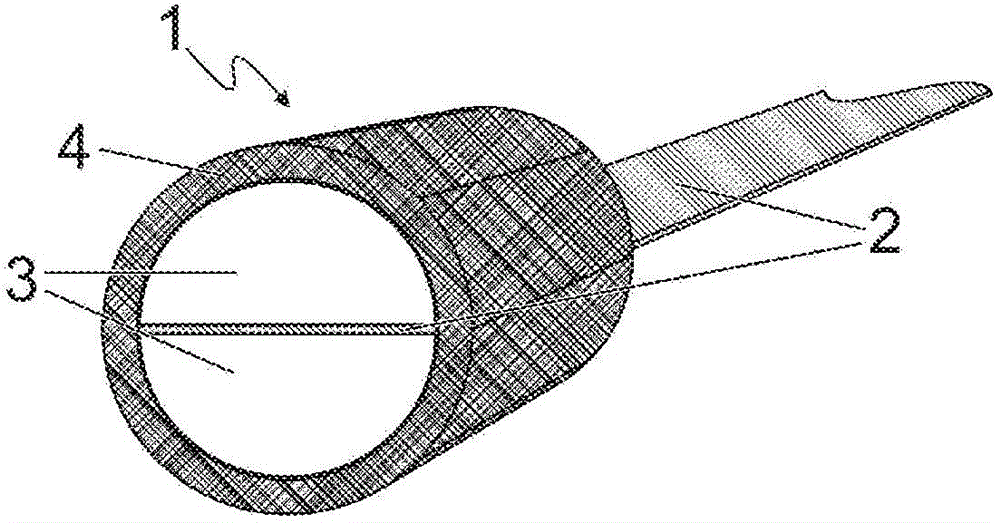

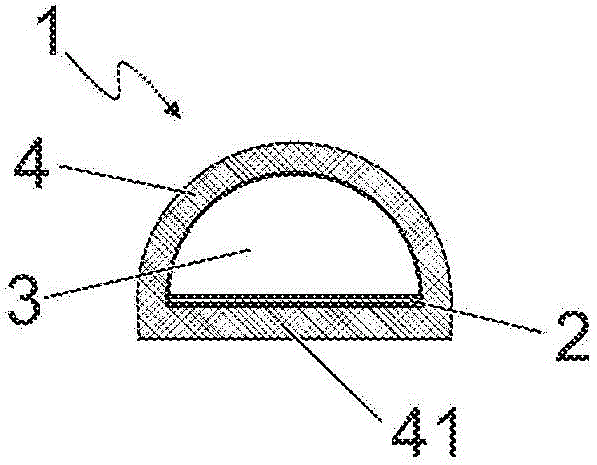

[0034] figure 1 Shown is a device 1 for introducing force into a tension element 2 consisting of fiber-reinforced plastic webbing laminations, comprising a clamping element 3 arranged on the tension element and having a contact surface with the tension element and at least one A rigid sleeve 4 is arranged around the clamping element and the tension part and thus exerts a clamping pressure on the tension part via the clamping element.

[0035] According to the invention, the clamping element consists of a plastic having a modulus of elasticity in the range of 1000 to 5000 MPa, a flexural tensile strength of ≧25 MPa, in particular 50 to 150 MPa, and a compressive strength of ≧25 MPa.

[0036] The stated values relate to measurements according to standard ISO 604 for modulus of elasticity and standard ISO 178 for flexural tensile strength and compressive strength.

[0037] As plastic for the clamping element, in principle any desired plastic with corresponding physical propert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com