Metamaterial antenna housing and antenna system

An antenna system and metamaterial technology, applied in the field of radome and antenna system, can solve the problems of large electromagnetic wave loss, reduce antenna radiation efficiency and gain, affect antenna electromagnetic performance, etc., and achieve the effect of high wave transmission characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

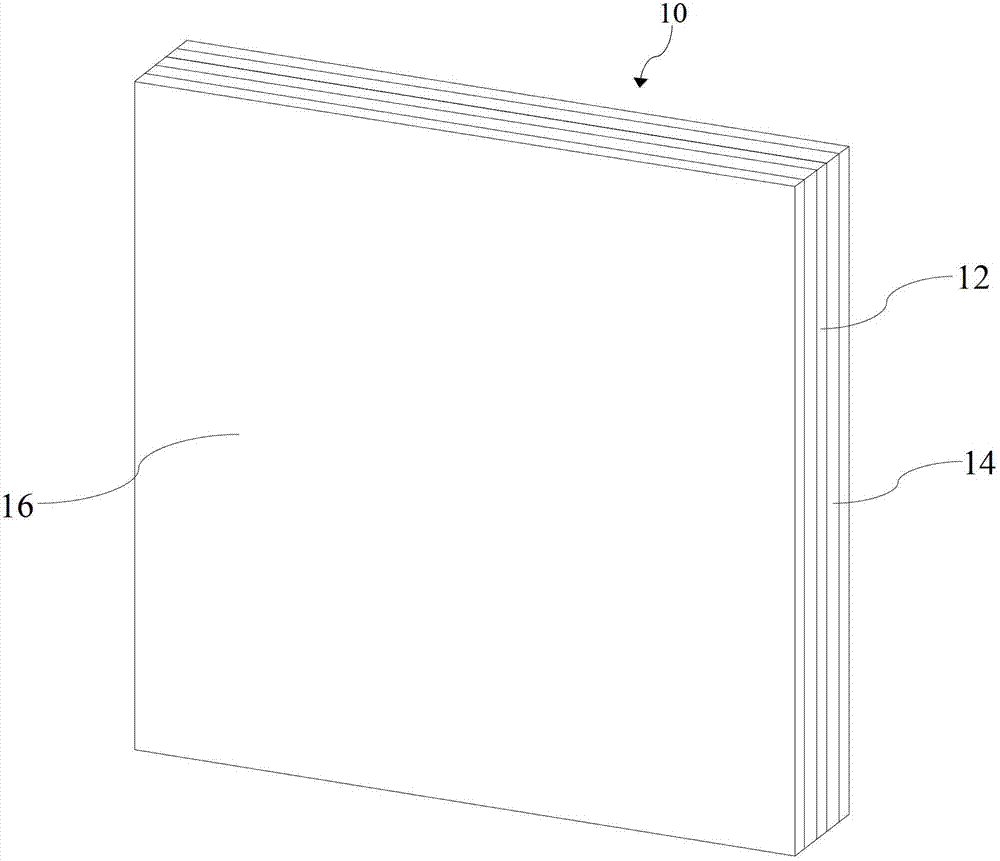

[0024] Such as figure 1 As shown, the metamaterial radome of the present invention is a multilayer metamaterial structure 10, which includes a first dielectric layer 12, two metal layers 14 respectively covering two opposite surfaces of the first dielectric layer 12 and two metal layers respectively covering The second dielectric layer 16 of the two metal layers 14 .

[0025] Both the first dielectric layer 12 and the second dielectric layer 16 are made of polymer materials, ceramic materials, ferroelectric materials, ferrite materials, ferromagnetic materials, etc., and the thickness of the first dielectric layer 12 is greater than that of each The thickness of the second dielectric layer 16, and the thickness of the two second dielectric layers 16 is equal. In this embodiment, the thickness of the first dielectric layer 12 is 1.9-2.1 mm, and the thickness of each second dielectric layer 16 is 0.4-0.6 mm.

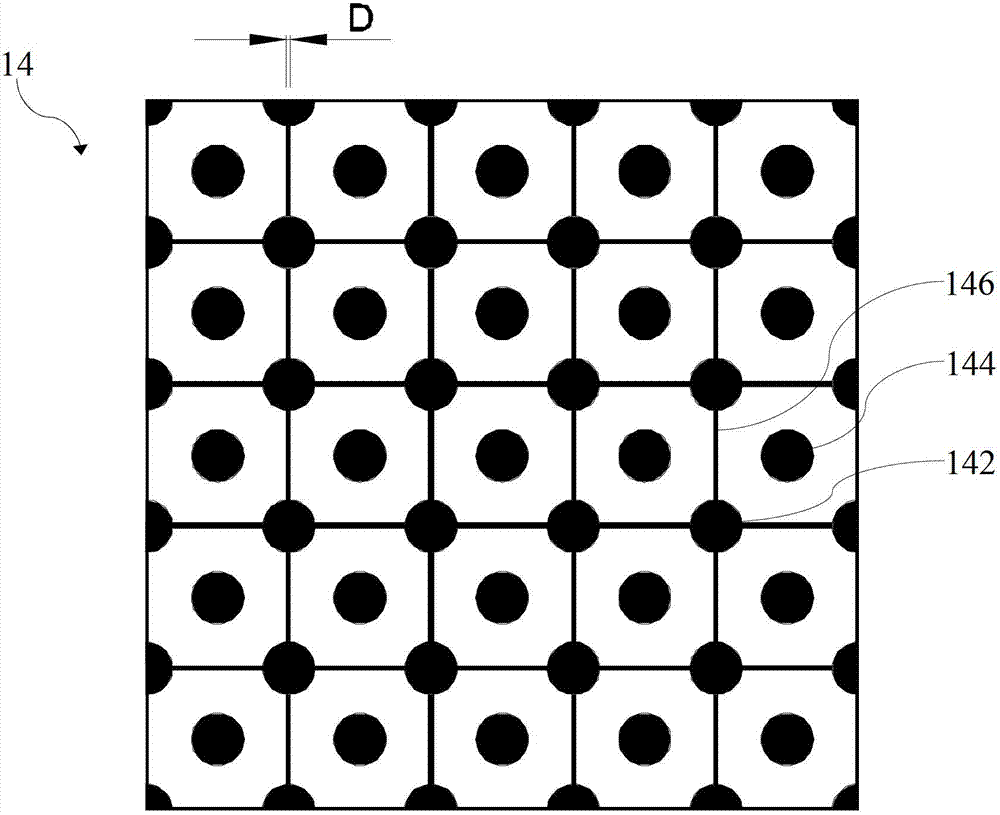

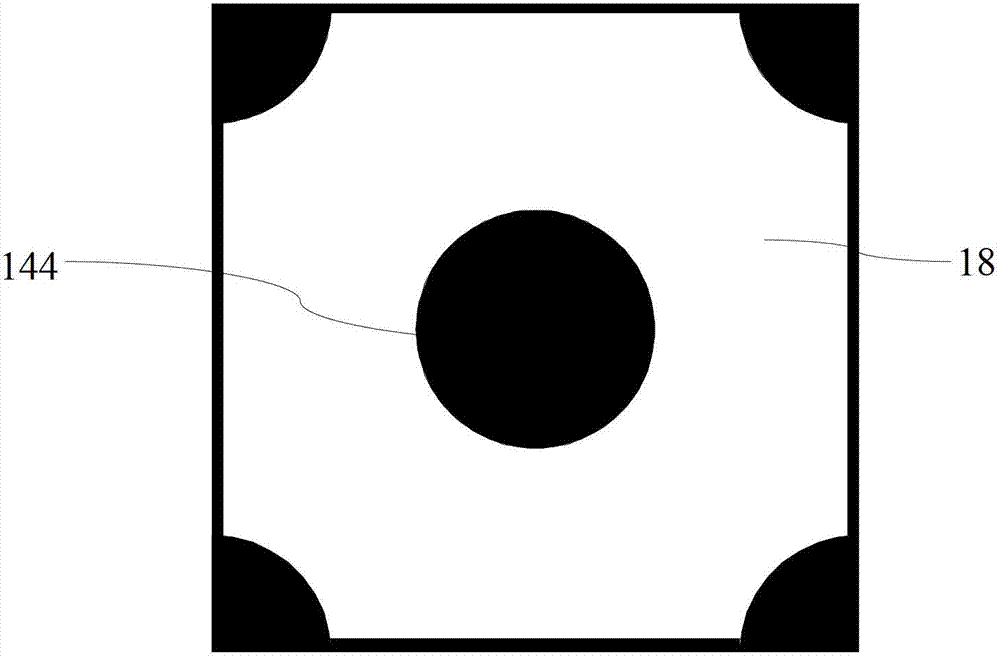

[0026] Such as figure 2 As shown, each metal layer 14 can be made...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com